Guide sleeve for installing aircraft braking wheel

A technology of guide sleeves and wheels, applied in the field of guide sleeves, can solve the problems of broken parts, inconsistencies, lack of axes of machine wheel assemblies and brake devices, etc., and achieve the effects of preventing bumps, convenient operation, and convenient ground operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

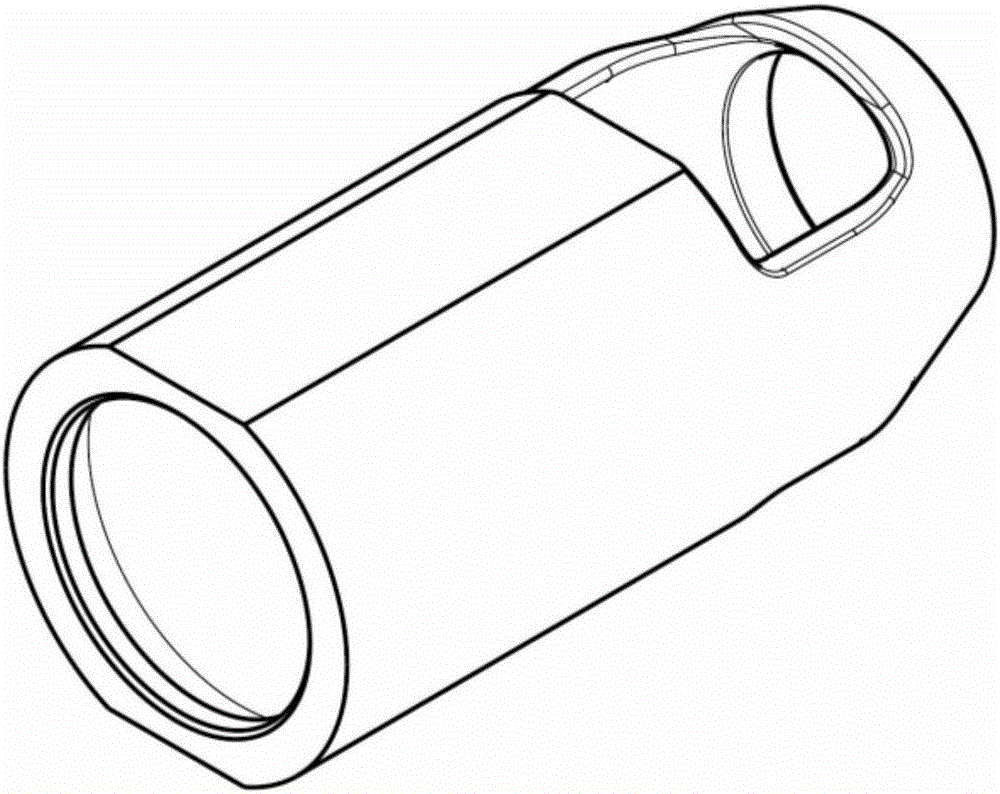

[0024] This embodiment is a guide sleeve for installing a brake wheel of a certain type of aircraft.

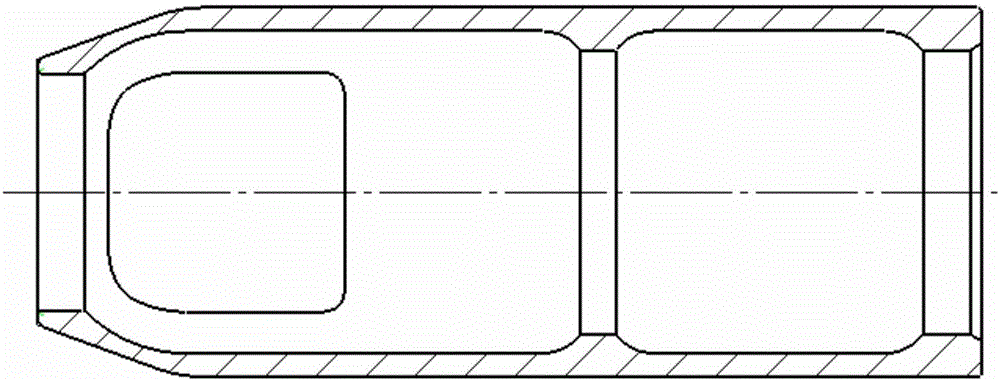

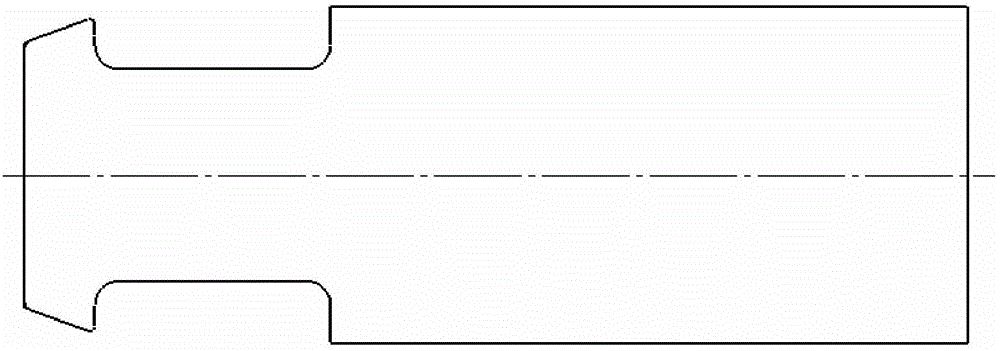

[0025] The guide sleeve 6 is cylindrical. The cylinder body of the guide sleeve is composed of an equal-diameter section and a cone section. The cylinder body of the equal-diameter section is located at one end of the guide sleeve, and its outer circular surface matches the inner circular surface of the bearing outer ring on the wheel assembly with a small clearance. There are two planes symmetrically distributed on the outer circle of the section, which can reduce the sliding friction force by reducing the contact area between the equal-diameter cylinder and the outer ring of the bearing outer ring of the wheel assembly, so that the guide sleeve and the wheel assembly are easy to move during installation and disassembly. , the plane can also play a role in reducing weight. The two radially protruding bosses on the inner surface cooperate with the outer surface of the landin...

Embodiment 2

[0029] This embodiment is a guide sleeve for installing a brake wheel of a certain type of aircraft. The guide sleeve of this embodiment has the same structure as the guide sleeve of Embodiment 1, only the dimensions are adjusted according to the shaft diameter of the landing gear and the size of the wheels, and high-strength steel materials are selected for use.

[0030] In this embodiment, the installation guide sleeve is selected from 45 steel, with a total weight of 8kg, and the surface treatment is bluish. The guide sleeve 6 has a length of 380mm and is composed of an equal-diameter section and a cone-section cylinder. The gap between the inner circular surfaces of the outer ring is 0.15mm, and two symmetrical planes are distributed on the outer circular surface. The planes are 245mm long, 35mm wide and 2mm deep. The inner circular surface of the equal-diameter section cylinder is 5mm and 150mm away from the end surface of the equal-diameter section, and each has a boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com