Method for preventing decarbonization through blank charging sequence control

A sequence control and anti-decarburization technology, applied in the field of metallurgy, can solve the problems of heating furnaces too late to adjust temperature, product heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

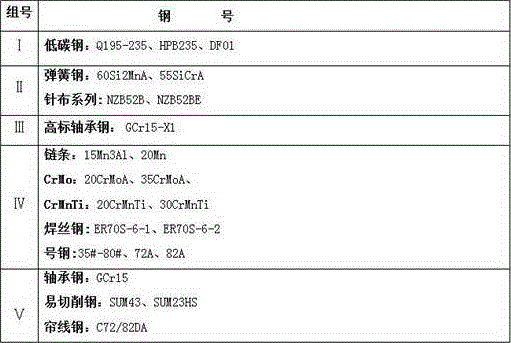

[0029] A method for preventing decarburization by controlling the sequence of blanks entering the furnace, classifying the heating temperatures of all steel types according to the composition, temperature, and sensitivity to temperature of the steel types, reducing the large difference in temperature, the sequence of entering the furnace is too close, and the heating furnace is too late Adjust the temperature to cause product heating defects; the specific requirements are as follows:

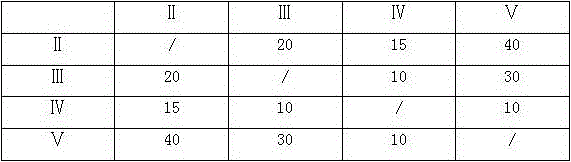

[0030] See Table 1 for the classification table of steel types. Through the above classification research, the sequence control and control principles of different steel types when entering the furnace are formulated. The same type of steel is prioritized together; the order of furnace loading is: Ⅱ → Ⅲ → Ⅳ → Ⅴ or Ⅴ → Ⅳ → Ⅲ → Ⅱ; type Ⅰ steel is used as the transition steel between any two types of Ⅱ-Ⅴ, and the quantity is more than 20 ; If the quantity of Class I steel is not enough, carry out e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com