A three-dimensional porous g-c3n4/c airgel based on cellulose and its preparation method

A cellulose airgel, three-dimensional porous technology, applied in the direction of carbon preparation/purification, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of difficult recycling, secondary pollution, etc., and achieve low cost, The effect of uniform pore size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

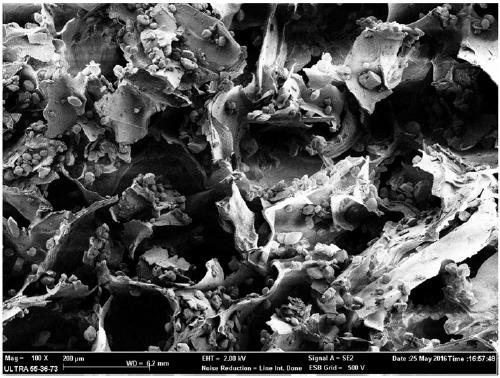

[0028] (1) Preparation of cellulose airgel: Dissolve 2g of cellulose powder in a pre-cooled sodium hydroxide / urea / water mixed solution with a mass ratio of 7:12:81 at -12°C, and stir vigorously to obtain a concentration of 2wt % cellulose solution; then add 1.5 g of cross-linking agent N, N'-methylenebisacrylamide, stir at room temperature for 30 minutes to carry out chemical cross-linking, wash with water and then freeze-dry to obtain cellulose airgel.

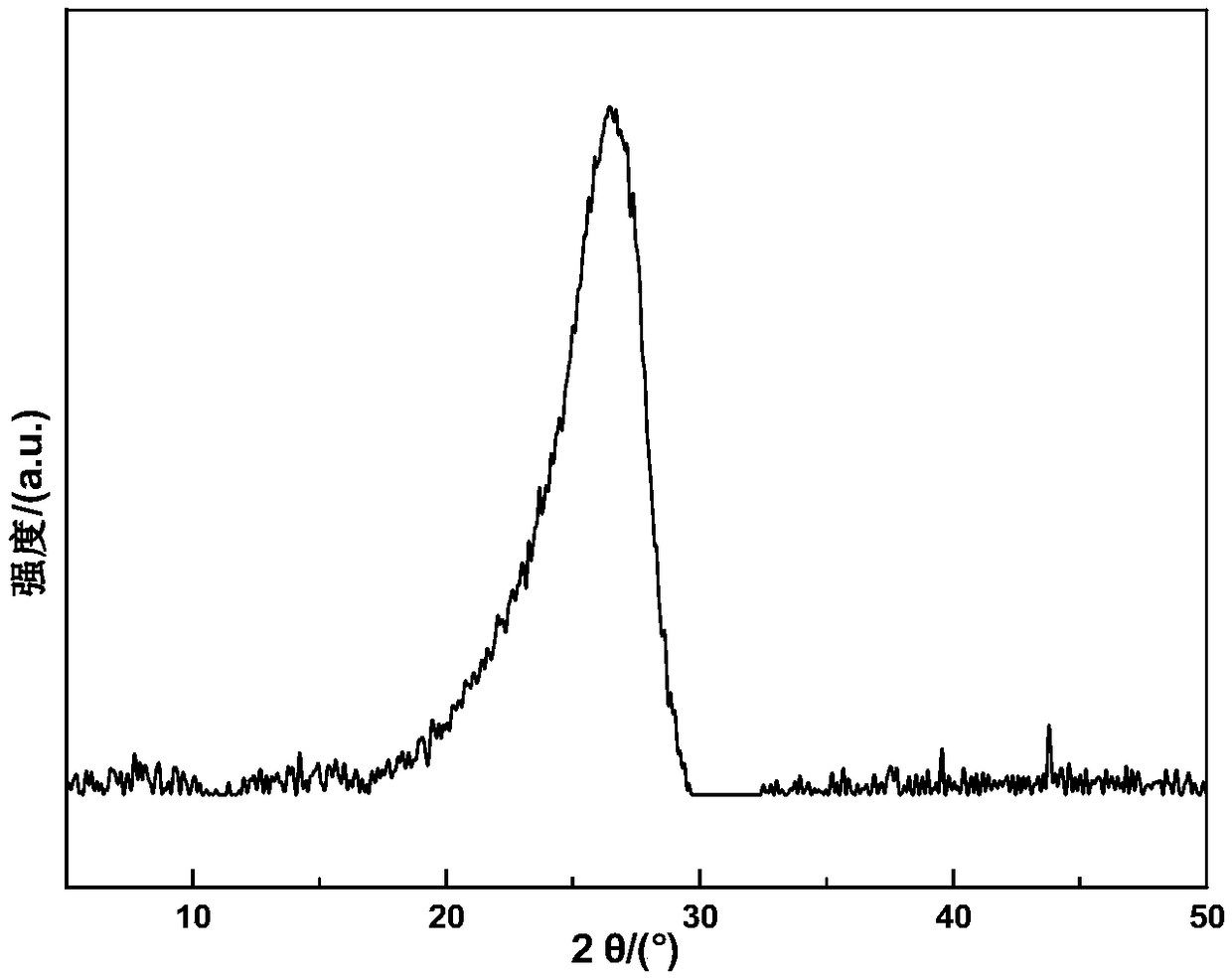

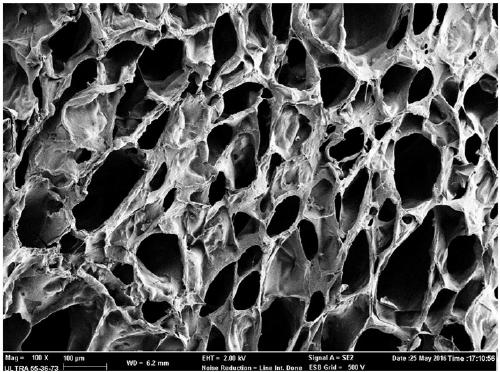

[0029] (2) Three-dimensional porous g-C 3 N 4 Preparation of / C airgel: Pour 5g of melamine into 300mL deionized water and stir to obtain a melamine suspension, then immerse the cellulose airgel prepared in step (1) in the melamine suspension, and then squeeze and absorb the suspension Melamine in the turbid liquid was freeze-dried or oven-dried at 60°C to obtain cellulose aerogels loaded with melamine; finally, the cellulose aerogels loaded with melamine was placed in a tube furnace, under the protection of argon, to The t...

Embodiment 2

[0032] (1) Preparation of cellulose airgel: Dissolve 4g of absorbent cotton in a pre-cooled sodium hydroxide / urea / water mixed solution with a mass ratio of 7:12:81 at -12°C, and stir vigorously to obtain a cellulose airgel with a concentration of 4wt%. Cellulose solution; then add 0.6 g of cross-linking agent N, N'-methylenebisacrylamide, stir at room temperature for 30 minutes to carry out chemical cross-linking, wash with water and then freeze-dry to obtain cellulose airgel.

[0033] (2) Three-dimensional porous g-C 3 N 4 Preparation of / C airgel: Pour 15g of melamine into 300mL deionized water and stir to obtain a melamine suspension, then immerse the cellulose airgel prepared in step (1) in the melamine suspension, and squeeze and absorb the suspension Melamine in the turbid liquid was freeze-dried or oven-dried at 60°C to obtain cellulose aerogels loaded with melamine; finally, the cellulose aerogels loaded with melamine was placed in a tube furnace, under the protection...

Embodiment 3

[0036](1) Preparation of cellulose airgel: Dissolve 4.5g of pulp pulp in a pre-cooled sodium hydroxide / urea / water mixed solution with a mass ratio of 7:12:81 at -12°C, stir vigorously to obtain a concentration of 4.5 wt% cellulose solution; then add 1.0 g of cross-linking agent N, N'-methylenebisacrylamide, stir at room temperature for 30 minutes to carry out chemical cross-linking, wash with water and then freeze-dry to obtain cellulose airgel.

[0037] (2) Three-dimensional porous g-C 3 N 4 Preparation of / C airgel: Pour 10g of melamine into 300mL deionized water and stir to obtain a melamine suspension, then immerse the cellulose airgel prepared in step (1) in the melamine suspension, and squeeze and absorb the suspension Melamine in the turbid liquid was freeze-dried or oven-dried at 60°C to obtain cellulose aerogels loaded with melamine; finally, the cellulose aerogels loaded with melamine was placed in a tube furnace, under the protection of argon, to Heat up to 550°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com