Bale wrapping machine

A packaging machine and rod mechanism technology, applied in packaging, agricultural machinery and implements, applications, etc., can solve the problems of complex structure, high manufacturing cost, easy failure of guide rail and chain transmission mechanism, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

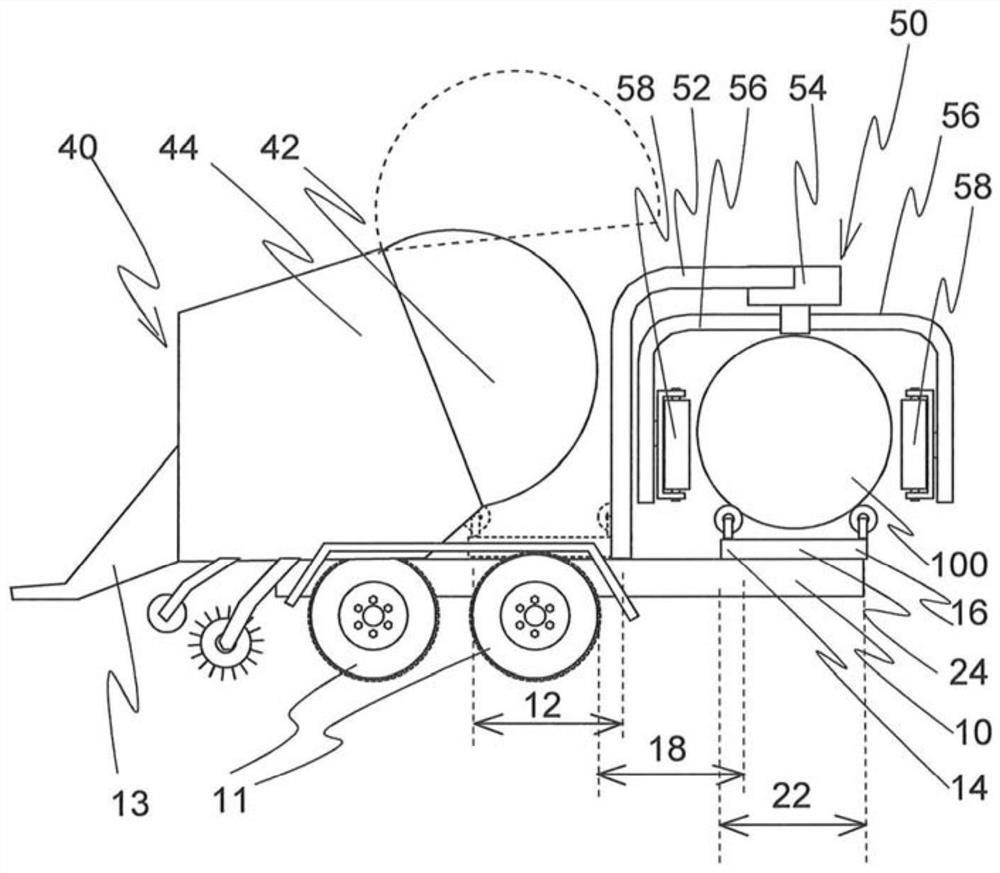

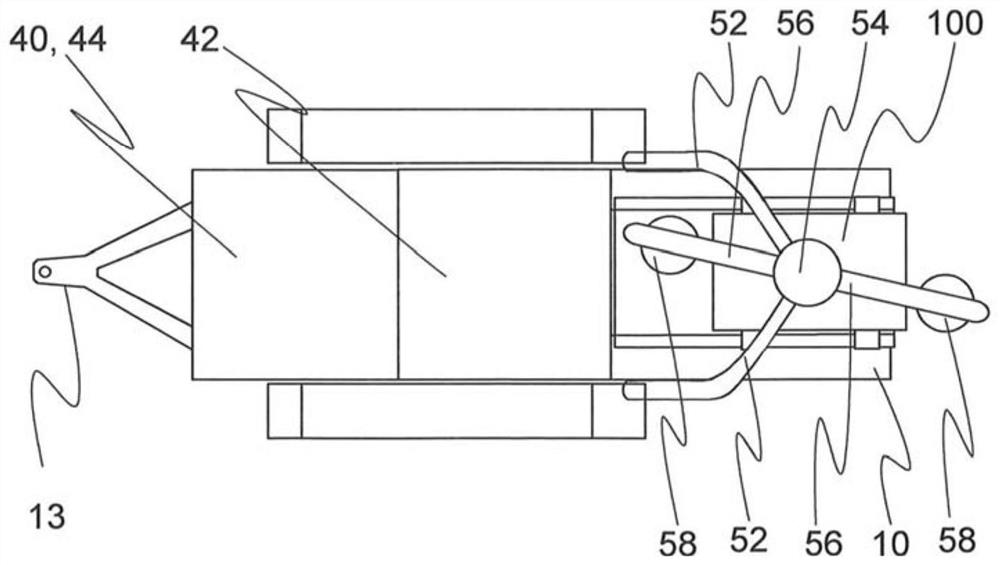

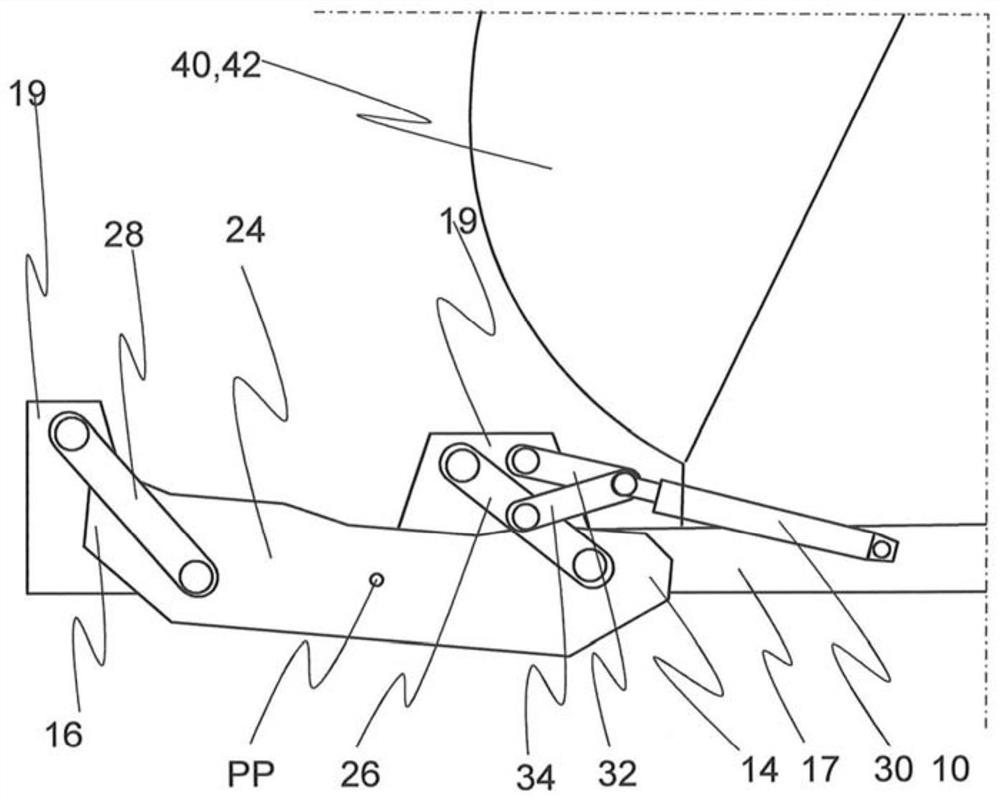

[0027] Figure 1a and Figure 1b An embodiment of a combination machine provided with the bale wrapper of the invention is illustrated. exist Figure 1a The combined machine is shown from the side in , and in Figure 1b The combined machine is shown from the top in . The combined machine has an elongated frame 10 comprising beam-type parts to which are attached two axles with wheels 11 at their ends. At a first end of the frame there is a tow bar 13 with a towing eyelet for fastening to a work machine or tractor vehicle. At the first end of the frame there is also a baling chamber 40, the edge of which facing the draw bar is provided with means for collecting material to be baled from the field and for guiding the material into the baling chamber. The baling chamber has a baling tool by which the baler forms the raw material supplied to the baling chamber, such as forage plants or hay, into round bales. The packing chamber comprises a front section 44 fixedly attached to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com