Automatic wire storage ring opening and closing device for winding machine

A technology of automatic opening and closing, winding machine, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as fatigue deformation, affecting winding operations, and unfavorable automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

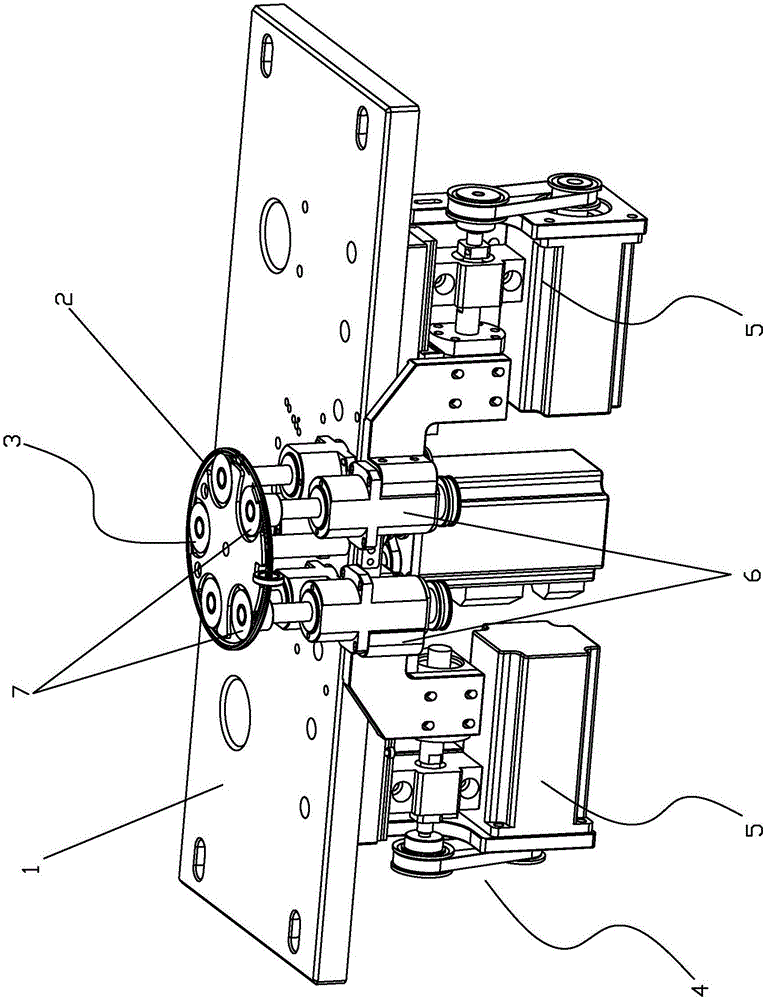

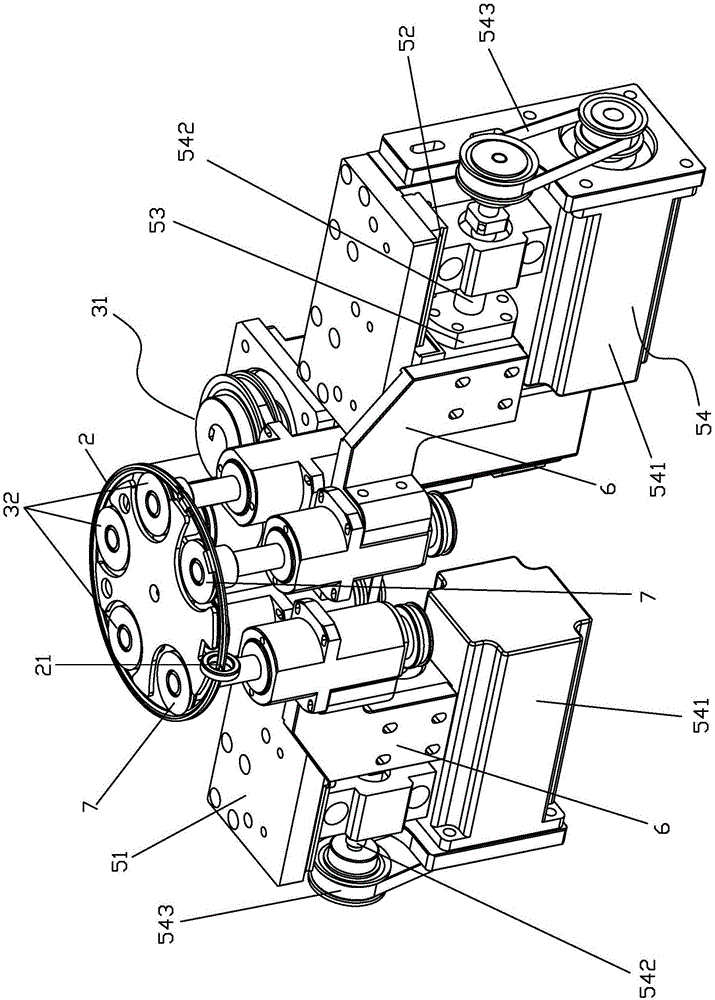

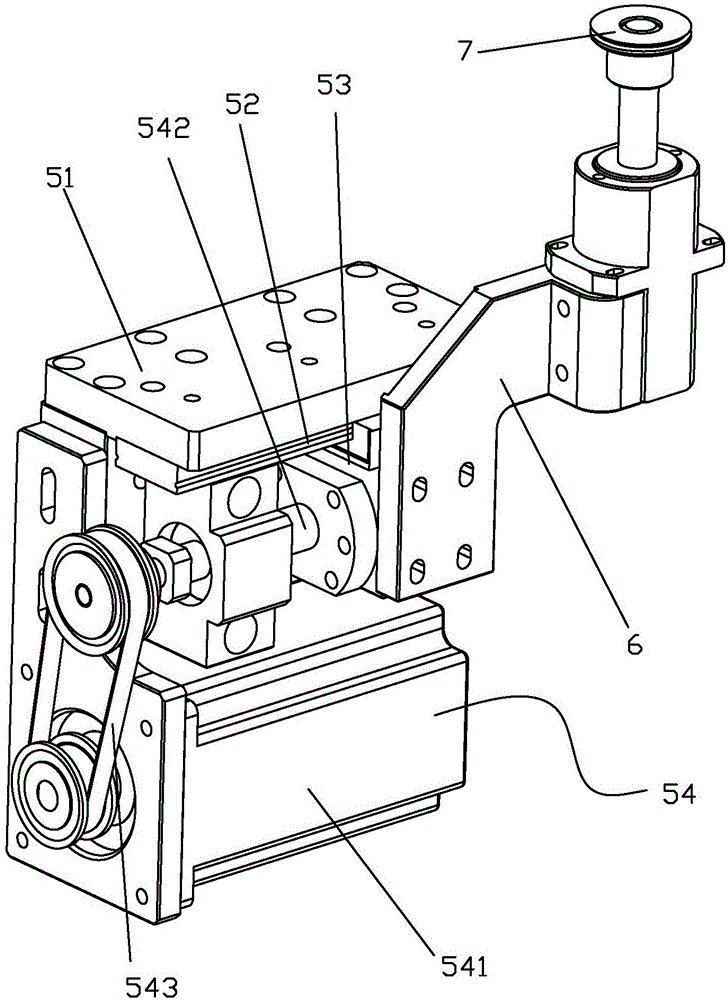

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0029] Such as Figure 1-5 As shown, an automatic opening and closing device for a wire storage ring for a winding machine includes a workbench 1 and a wire storage ring 2 arranged on the workbench 1. The wire storage ring 2 is provided with an opening 21, and on the workbench 1 There is a rotary drive mechanism 3 for driving the wire storage ring 2 to rotate, and an opening and closing ring mechanism 4 for opening and closing the wire storage ring 2 along the opening 21 in a plane, and the opening and closing ring mechanism 4 can also be closed by multiple actions Storage ring 2. The open-loop mechanism 4 includes an open-loop power assembly 5 arranged on the workbench 1, and an open-loop support part 6 driven by the open-loop power assembly 5 to reciprocate. The open-loop support part 6 extends into the ring of the wire storage ring 2 inside.

[0030] This device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com