Method for designing flow coefficient 0.0242 pipeline compressor model grade and impeller

A pipeline compressor and flow coefficient technology, applied in the field of compressors, to achieve the effect of small span, lower working speed, and narrow bearing span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

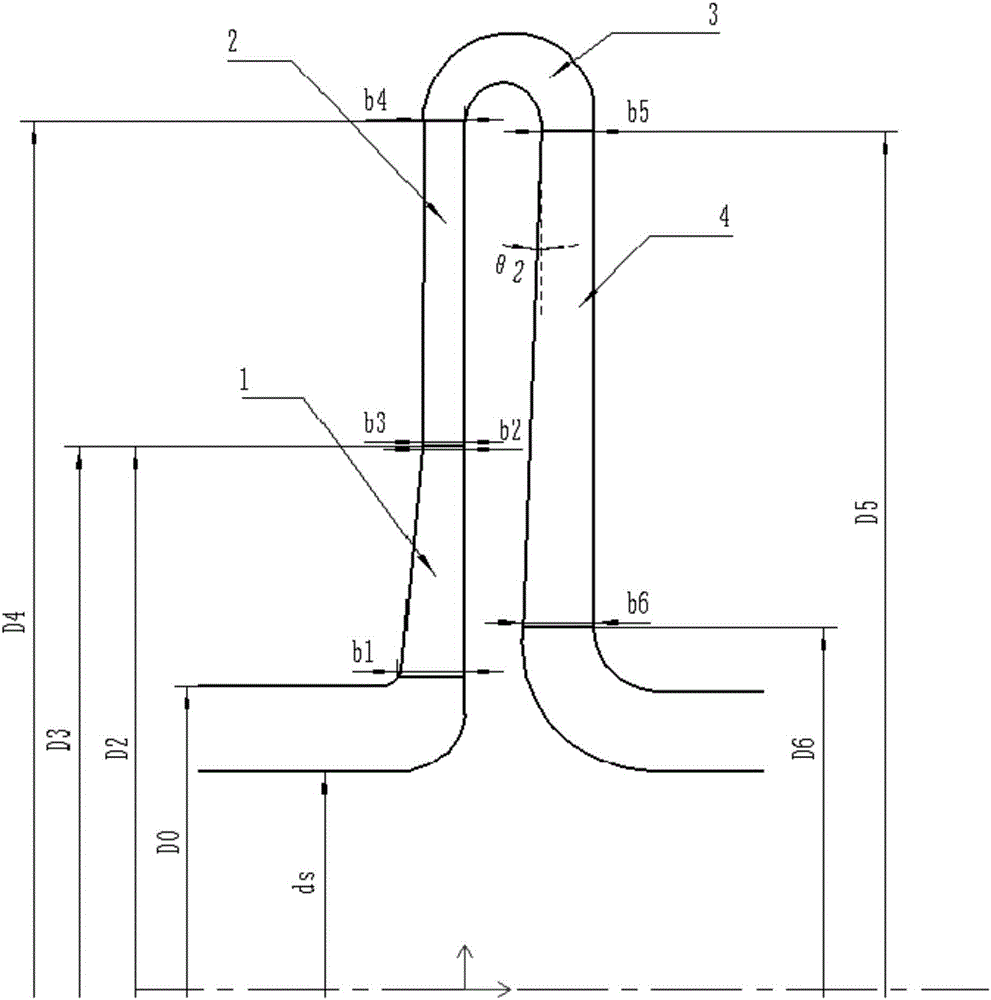

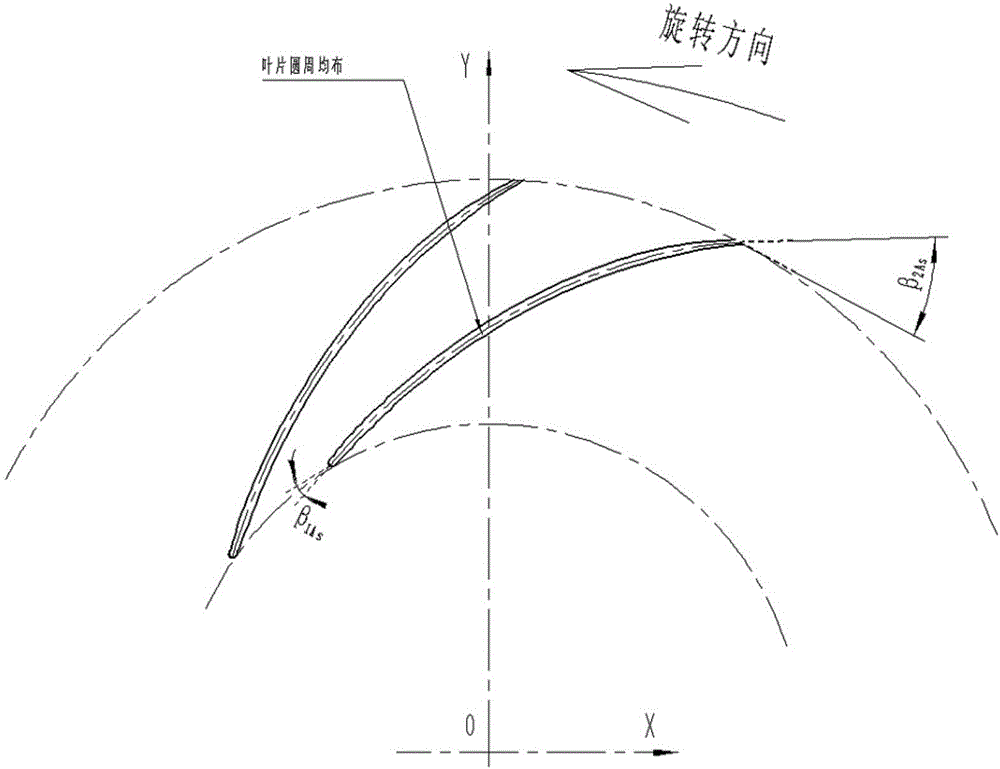

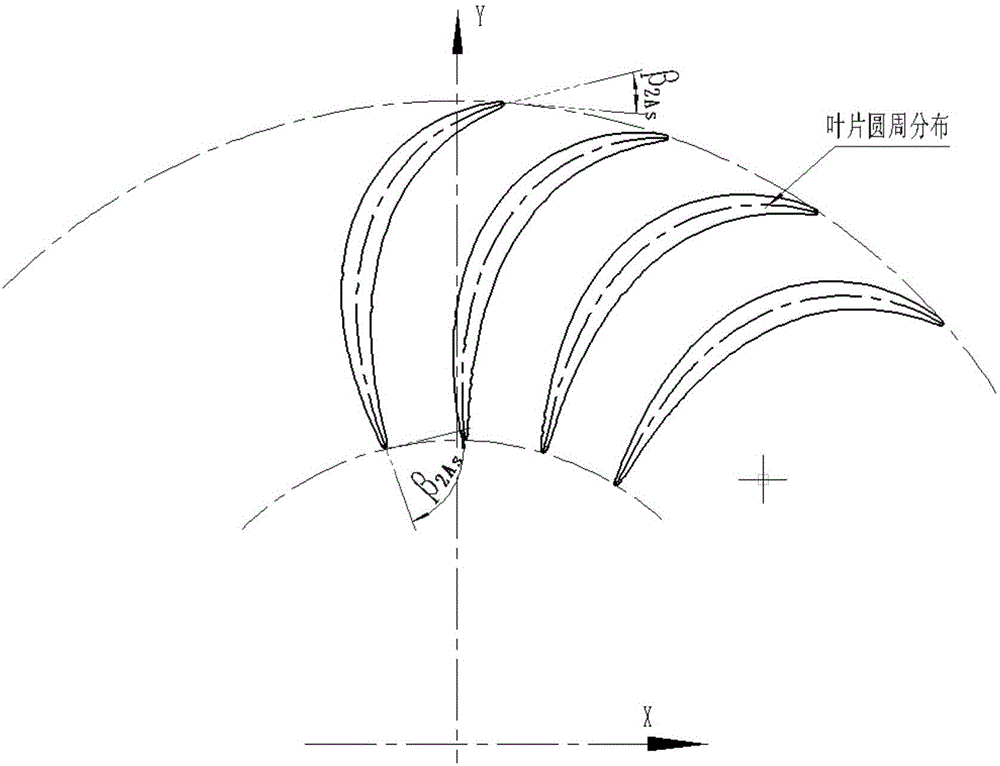

[0034] See figure 1 , The embodiment of the present invention provides a pipeline compressor model stage with a flow coefficient of 0.0242, which is suitable for the modular design of pipeline compressors and other light medium compressor products, including impeller 1, vaneless diffuser 2, curve 3 and Reflux 4, in which the impeller 1 is located at the inlet of the model stage, the outlet of the impeller 1 is provided with a vaneless diffuser 2, and the recirculation device 4 is located at the outlet of the model stage, between the vaneless diffuser 2 and the reflow 4 Connect through curve 3. The machine Mach number that can be used in this model level M u2 =0.35~0.65, design point discharge coefficient Φ1 =0.0242, design point energy coefficient τ=0.585, variable efficiency η under design flow coefficient working conditions under each Mach number pel =0.819~0.825, the applicable flow range is 60%-150% of the design point. Specific performance curve such as Figure 17-19 Sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outlet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com