Graphene heating fabric and method for preparing same

A heating fabric and graphene technology, applied in the field of fabrics, can solve the problems of non-heating fabrics and cumbersome preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the graphene heating fabric in this implementation comprises the following steps:

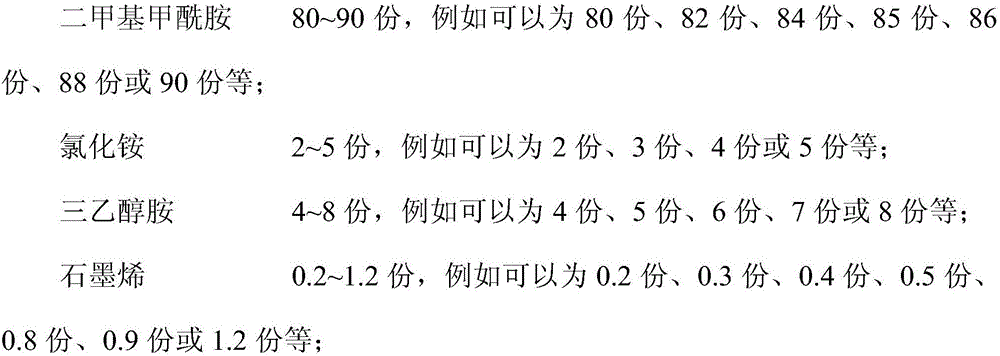

[0024] Configuration graphene printing paste, by mass parts, graphene printing paste comprises the following components:

[0025]

[0026] The graphene printing paste is printed on the fabric, and the graphene heating fabric is obtained by printing, drying, steaming, color fixing, washing, and expanding according to the pattern.

Embodiment 2

[0028] The preparation method of the graphene heating fabric in this implementation comprises the following steps:

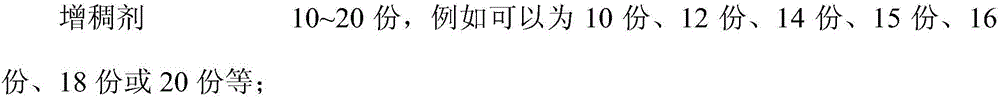

[0029] Configuration graphene printing paste, by mass parts, graphene printing paste comprises the following components:

[0030]

[0031] Graphene printing paste is printed on the fabric, and the fabric is fixed between the upper and lower molds of the embossing machine, and the molds are closed. The fabric is transported to the bottom of the pressing plate through the transmission part, and the heating chamber is started to heat the fabric, embossing Press the heated fabric with rollers and bottom rollers, dry at 135°C for 30s, steam at 120°C for 8 minutes, wash at 65°C at a rate of 10m / min, and at 126°C at a rate of 36m / min. The expansion is carried out at a rate of min to obtain a graphene heating fabric.

Embodiment 3

[0033] The preparation method of the graphene heating fabric in this implementation comprises the following steps:

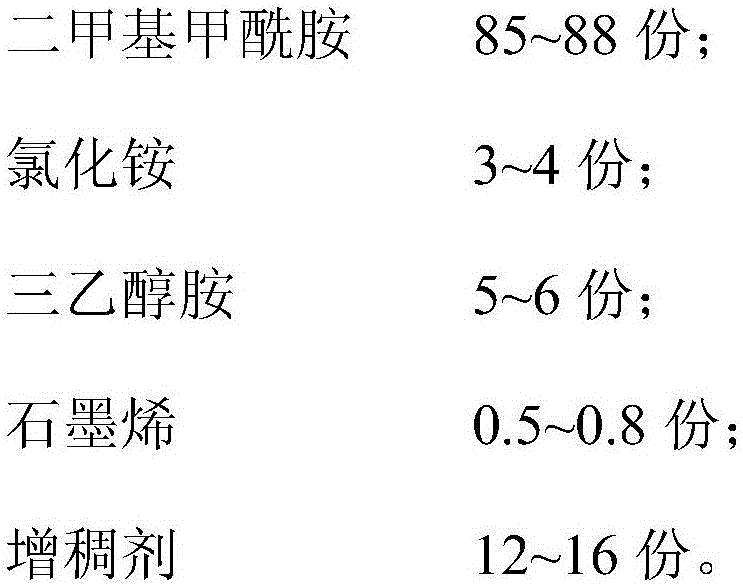

[0034] Configuration graphene printing paste, by mass parts, graphene printing paste comprises the following components:

[0035]

[0036] Graphene printing paste is printed on the fabric, and the fabric is fixed between the upper and lower molds of the embossing machine, and the molds are closed. The fabric is transported to the bottom of the pressing plate through the transmission part, and the heating chamber is started to heat the fabric, embossing Press the heated fabric with rollers and bottom rollers, dry at 142°C for 20s, steam at 122°C for 7 minutes, wash at 64°C at a rate of 9m / min, and at 126°C at a rate of 36m / min. The expansion is carried out at a rate of min to obtain a graphene heating fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com