Scanning digital high-speed inkjet printing machine

An inkjet printing machine and digital technology, applied in the textile and printing fields, can solve the problems of limiting the quantity of receiving and discharging materials, low production efficiency, limiting the amount of materials prepared, etc., to solve the problem of material and labor loss, clean workshop production Environment, effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

[0016] When the digital inkjet department performs inkjet printing, the printed matter (rolled printed matter) needs to be kept in a static state. After one round of inkjet printing is completed, the printed matter is driven forward by a distance of one printing unit for the second round of inkjet Printing; the printed matter is always in a state of intermittent motion. Therefore, in a conventional digital inkjet printing machine, the unwinding part and the winding part can only move intermittently accordingly, which brings many disadvantages.

[0017] The present invention has been improved for this purpose, and now further description will be given in conjunction with the embodiments shown in the accompanying drawings.

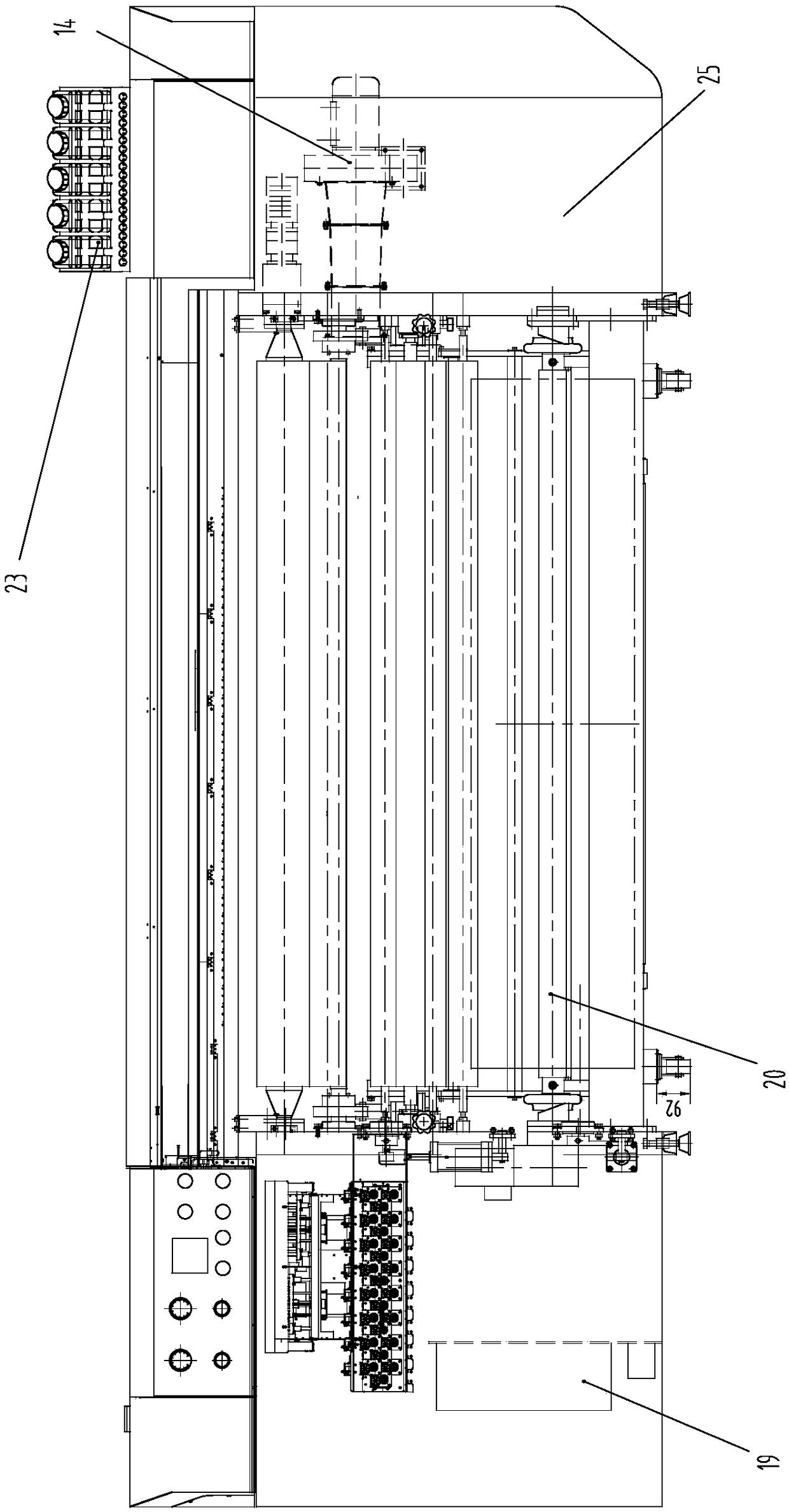

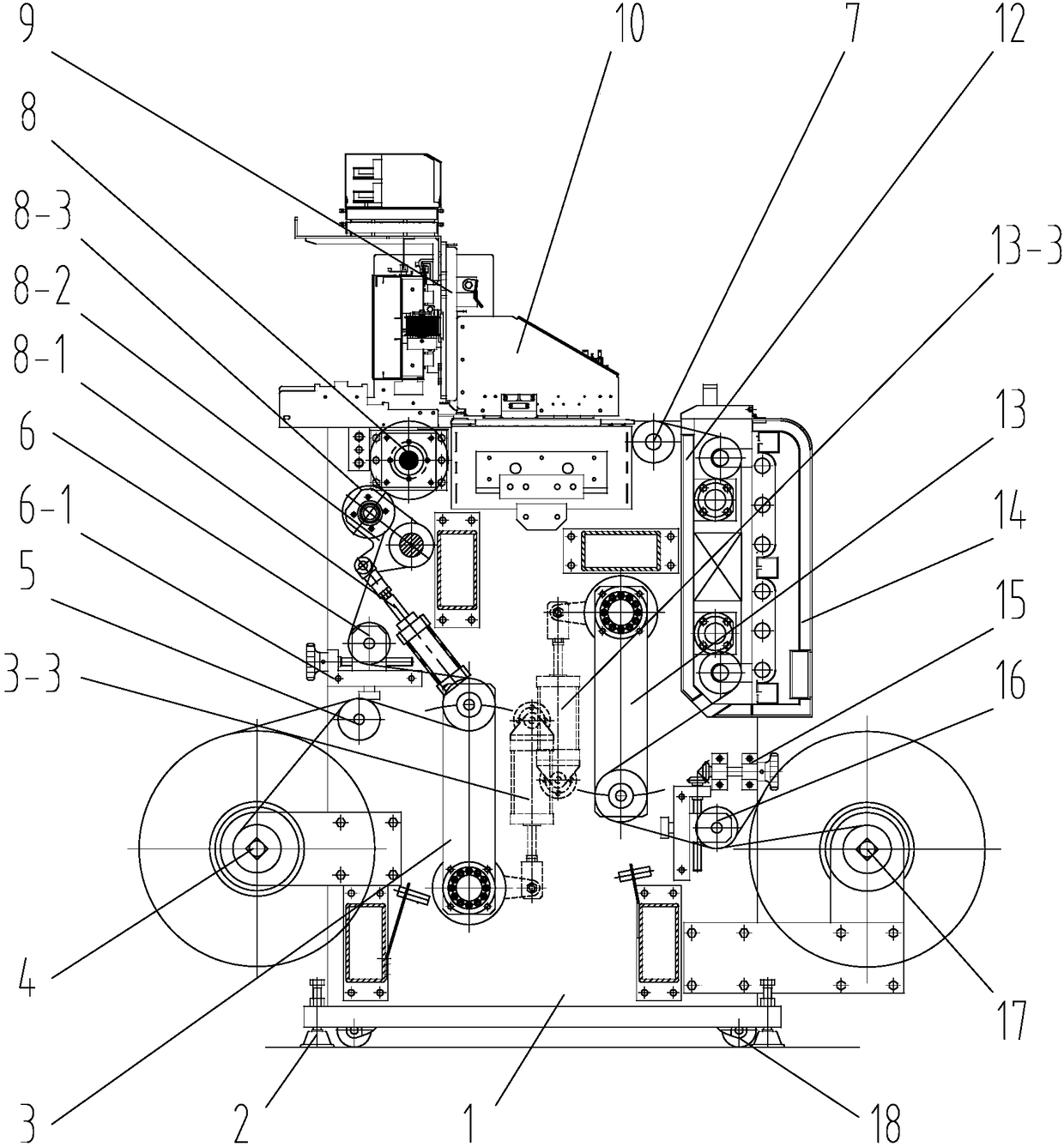

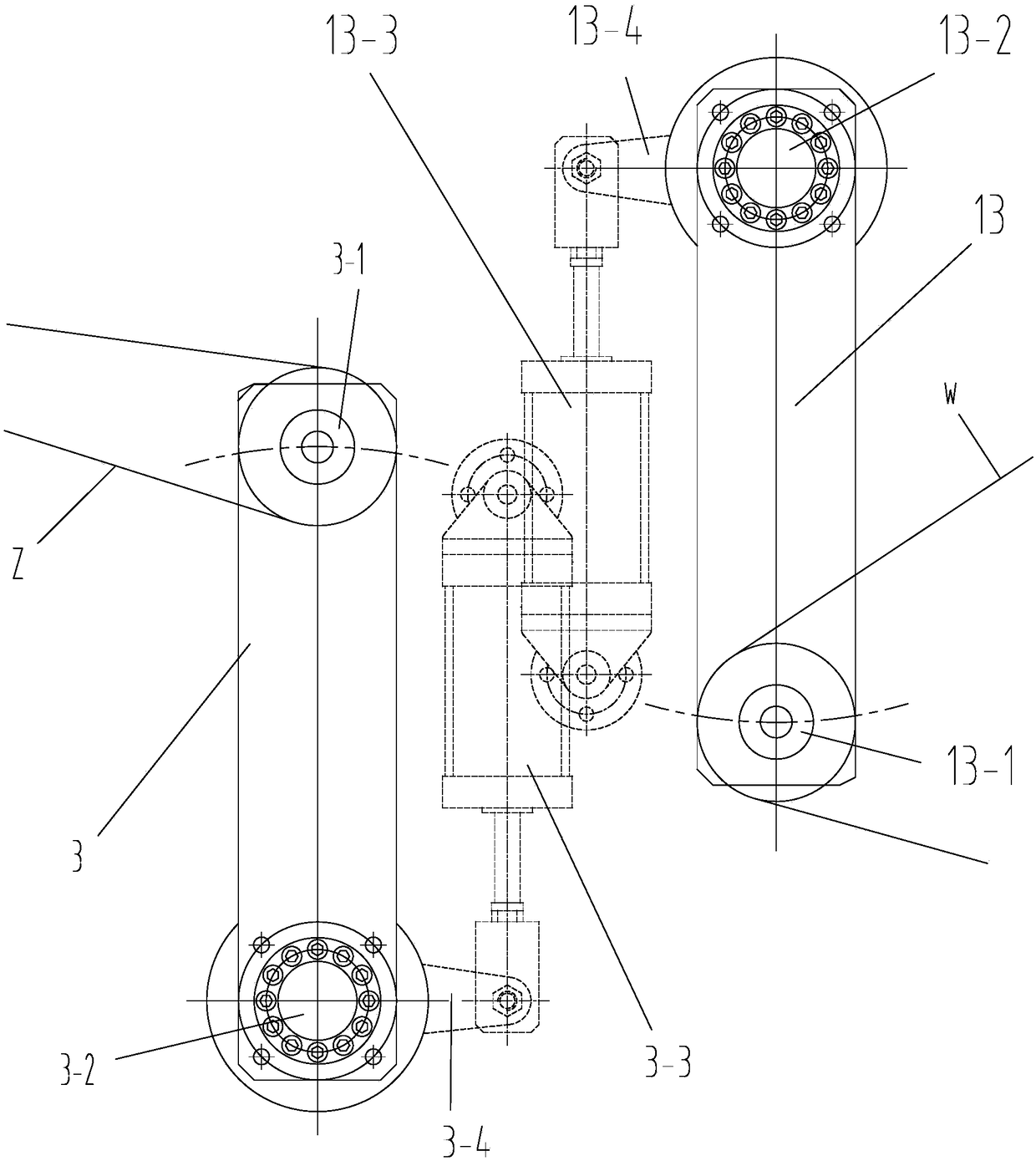

[0018] As shown in the figure, a scanning digital high-speed inkjet printing machine includes a discharge part 4, a traction part 8, a digital inkjet part 9, a drying part and The unwinding section 17; the unwinding se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com