Pipe welding jig and welding method

A technology for pipe fitting welding and pipe fittings, which is applied in the field of pipe fitting welding fixtures and welding, can solve the problems of high scrap rate, easy relative displacement, reverse welding of pipe fitting sheet metal parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

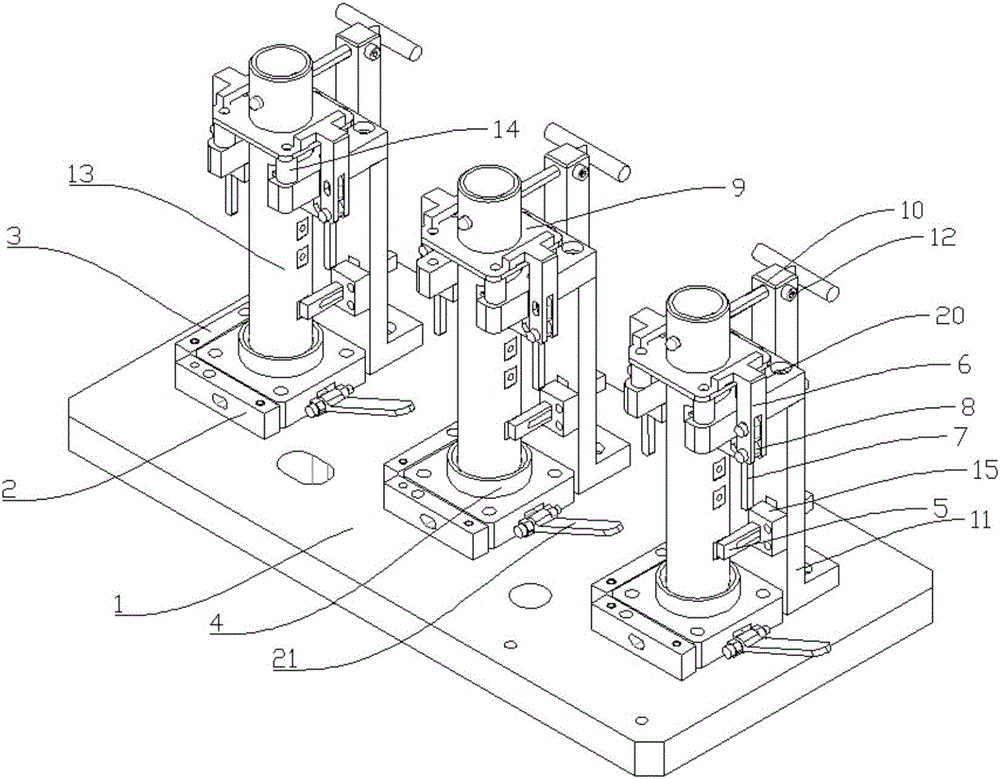

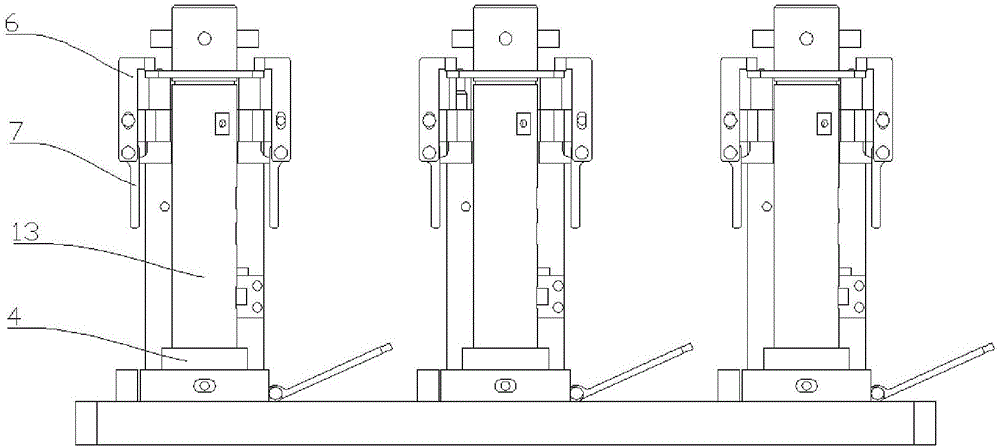

[0036] In order to achieve the purpose of the present invention, as shown in the figure, an embodiment of the present invention is:

[0037] The pipe fitting welding jig is used for welding the pipe fittings 13 and the sheet metal parts 9. It includes a jig bottom plate 1 and at least one set of pipe fitting welding units connected to the jig bottom plate 1. The pipe fitting welding unit includes: a pipe fitting positioning mechanism for The positioning of the pipe fitting 13; the anti-rotation mechanism of the pipe fitting is used to prevent the rotation of the pipe fitting 13 during welding; the positioning mechanism of the sheet metal part is used for the positioning of the sheet metal part 9; the pressing mechanism of the sheet metal part is used for pressing the sheet metal part 9 , one end of the pipe fitting 13 is provided with a positioning hole, the pipe fitting positioning mechanism includes a pipe fitting lower positioning block 4 connected with the jig bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com