Pulverizing device for fan and fan comprising pulverizing device

A crushing device and fan technology, which is applied in road cleaning, grain processing, construction, etc., can solve the problems of affecting the suction power of the fan, troublesome configuration and installation, and many production processes, so as to achieve good crushing and suction effects and easy disassembly and assembly And maintenance, crushing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

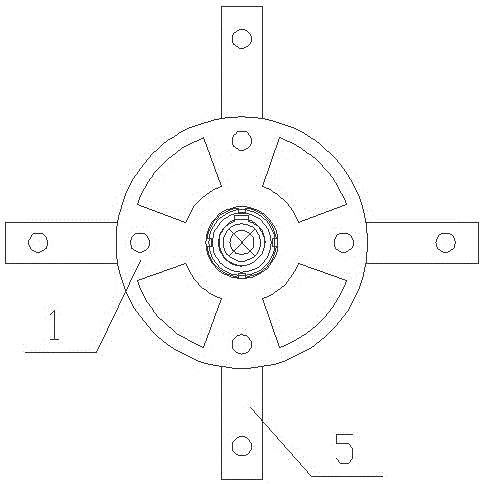

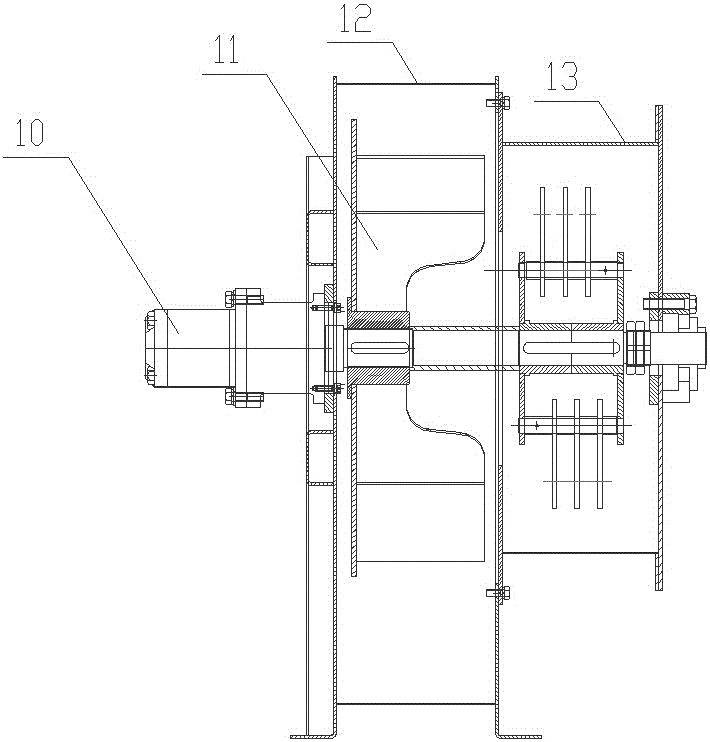

[0020] Combine below Figure 1 to Figure 3 The pulverizing device for the fan of the present invention and the fan with the pulverizing device are described in further detail.

[0021] Such as figure 1 with figure 2 As shown, the crushing device for a fan of the present invention mainly includes a shaft sleeve 1, a rotating disk end plate 2, a connecting shaft 3, a crushing blade 5, and a transmission shaft 9.

[0022] The shaft sleeve 1 and the rotating disk end plate 2 together constitute the rotating disk, the shaft sleeve 1 is a ring body, the rotating disk end plate 2 is a disc shape, and the shaft sleeve 1 is fixed at the center of one end surface of the rotating disk end plate 2. The rotating disk The weight-reducing holes are evenly distributed on the end plate 2.

[0023] The rotating disc is a pair, and the two rotating discs are distributed symmetrically. The end of the sleeve 1 that is not connected to the end plate 2 of the rotating disc is the symmetry plane. The end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com