Stacked mems sensor package, chip and manufacturing method thereof

A sensor chip and manufacturing method technology, applied in the sensor field, can solve the problems that restrict the intelligence of MEMS sensors, small size, high cost of MEMS sensors, low sensor performance, etc., so as to improve the design level and function, reduce process costs, The effect of reducing interference and circuit noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

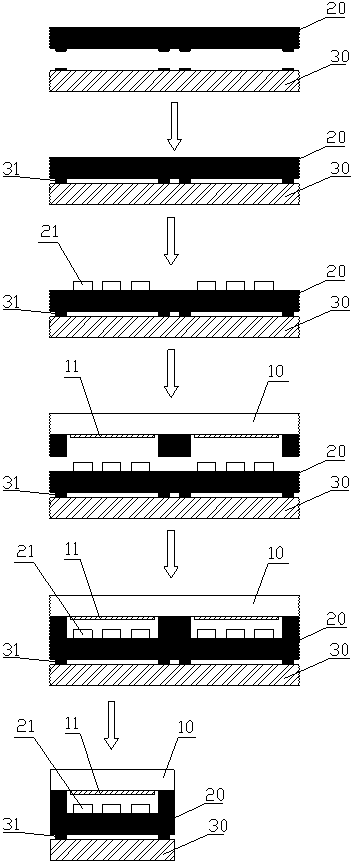

[0041] Embodiment 1: see figure 1 , a stacked MEMS sensor package, comprising: a cover plate 10 for packaging; an acquisition wafer 20, on which an acquisition circuit and a MEMS structure 21 are formed, and the acquisition circuit cooperates with the MEMS structure 21 to realize sensor acquisition signals Function; a processing wafer 30, on which a processing circuit is formed, used to control the acquisition circuit and the MEMS structure 21 to collect signals and process and output the collected signals; the processing wafer 30, the collection wafer 20 and the cover The board 10 is formed by bottom-up bonding using a wafer-level bonding process, wherein a MEMS structure packaging cavity is formed between the cover plate 10 and the collection wafer 20 , and between the collection wafer 20 and the processing wafer 30 Electrical interconnection is realized through conductive bridge piers 31 .

[0042] Further, the lower surface of the cover plate 10 also has a getter material...

Embodiment 2

[0060] Example 2: see Figure 5 , this embodiment also provides a stacked MEMS sensor package, the other parts are the same as in Embodiment 1, the difference is that: the processing wafer 30 is two wafers, which are processing wafer 1 (30a) and processing wafer 1 (30a) respectively. Circle 2 (30b). Preferably, the lower surface of the cover plate 10 also has a getter material layer 11 for realizing a vacuum environment in the packaging cavity, which is suitable for infrared thermal imaging sensors or other MEMS sensors that require vacuum packaging. The conductive bridge piers may be metal piers, or may be made of other materials capable of realizing electrical interconnection. The acquisition circuit adopts 0.13μm~0.5μm integrated circuit technology; the processing circuit adopts 14nm~180nm integrated circuit technology.

[0061] Same as Embodiment 1, the processing circuit on the wafer can include a central processing unit CPU or a microprocessor MPU with control, calcula...

Embodiment 3

[0071] Embodiment 3: see Figure 8, this embodiment also provides a stacked MEMS sensor package, the other parts are the same as in Embodiment 1, the difference is that: the acquisition wafer 20 is two wafers, which are acquisition wafer 1 (20a) and acquisition wafer 1 (20a) respectively. In circle 2 (20b), MEMS structures 21a and 21b are grown on acquisition wafer 1 and acquisition wafer 2, respectively. Here, the functions implemented by the MEMS structures 21a and 21b may be the same or different, and are driven by the acquisition circuit on the acquisition wafer. Preferably, the lower surface of the cover plate 10 also has a getter material layer 11 for realizing a vacuum environment in the packaging cavity, which is suitable for infrared thermal imaging sensors or other MEMS sensors that require vacuum packaging. The conductive bridge piers may be metal piers, or may be made of other materials capable of realizing electrical interconnection. The acquisition circuit adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com