Vapor deposition and thin film collecting mechanism

A material receiving mechanism and a technology for evaporating film, applied in metal processing and other directions, can solve the problems of incomplete metal film cutting, no shock absorption and buffering effect, insufficient metal film tension, etc., so as to reduce preparation time and improve flatness. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

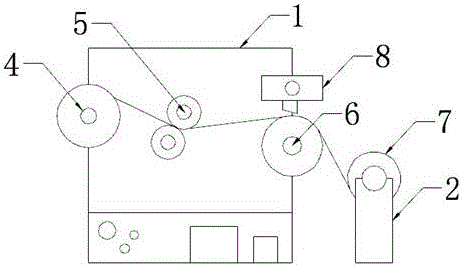

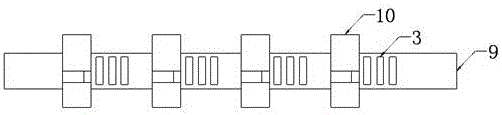

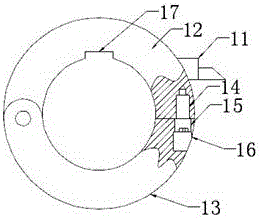

[0026] An evaporation film receiving mechanism, comprising a slitting support 1 and a winding support 2, the slitting support 1 is provided with a transmission device and a cutting device, and the rewinding support 2 is provided with a winding roller 7, the Said conveying device comprises material receiving rotating shaft 4, rolling straight rotating shaft 5 and cutting rotating shaft 6, and said cutting device comprises cutter shaft fixed support 8, cutter shaft 9, knife seat 10 and cutting knife 11, and described cutting knife 11 is installed in knife seat 10, the knife seat 10 is set on the cutter shaft 9, and the knife shaft 9 is installed on the fixed frame of the knife shaft 9, and the knife seat 10 is formed by connecting the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com