Control method for improving surface quality of hot rolled variety steel

A control method and surface quality technology, applied in metal rolling, temperature control, metal rolling, etc., can solve the problems of a large amount of corrosion on the surface between layers, affecting product quality and customer interests, etc., to reduce customer quality objections and ensure cooling Function, the effect of improving the quality of hot-rolled products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation process of the present invention is completely realized in the computer program to automatically control the opening and closing of the G roller table, the pinch roller, the winding help roller, and the cooling water of the reel equipment. According to the strip material code sent by the secondary computer, the hot-rolled steels that are prone to corrosion are distinguished, and then the cooling water opening and closing of the G roller table, pinch rollers, auxiliary winding rollers, and reels are controlled respectively.

[0019] When the material code is easy-to-corrosion steel, turn off the cooling water of all equipment when coiling steel; when the steel is rolled, turn on the cooling water of all equipment;

[0020] When the material code is not an easy-to-corrosion steel, the program uses the cooling water control logic of the original coiling equipment.

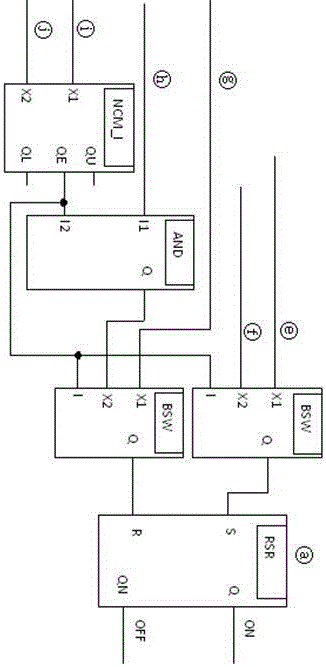

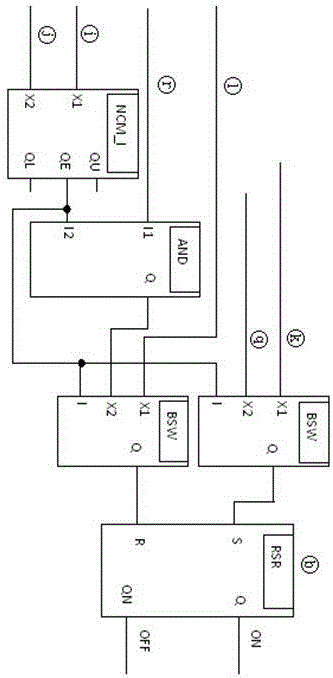

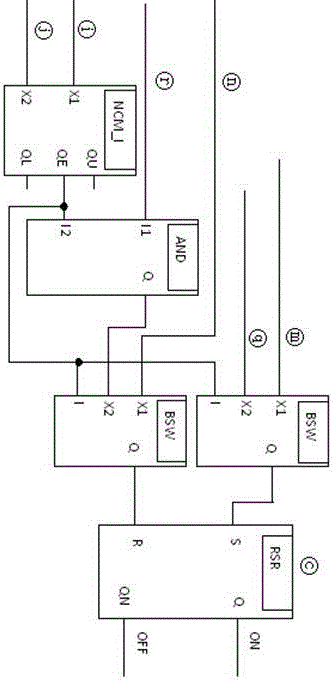

[0021] figure 1 As shown, NCM_I is a comparison integer logic block: X1 and X2 are input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com