Novel material mixer applied to garbage materials

A mixing machine and material mixing technology, which is applied to mixers, mixers with rotating stirring devices, biofuels, etc., can solve problems such as easy blockage of equipment, uneven mixing, and different particle sizes, so as to avoid Dust problem, effective material mixing, effect of reducing equipment size and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

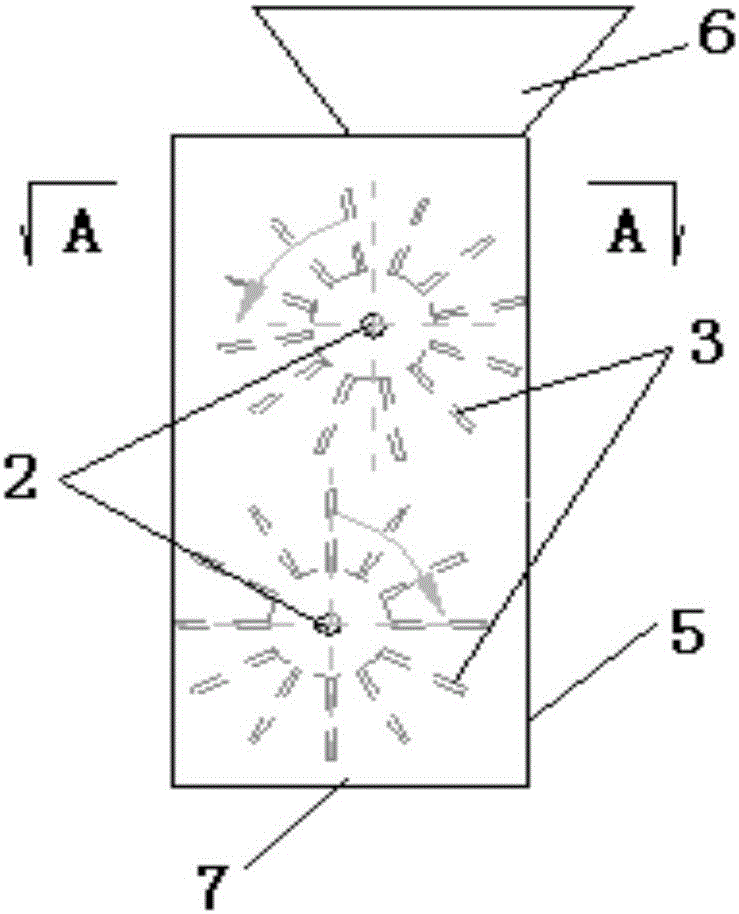

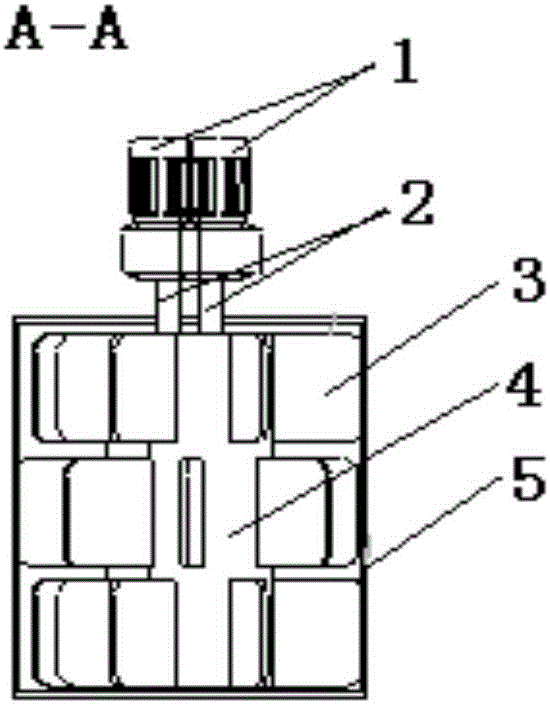

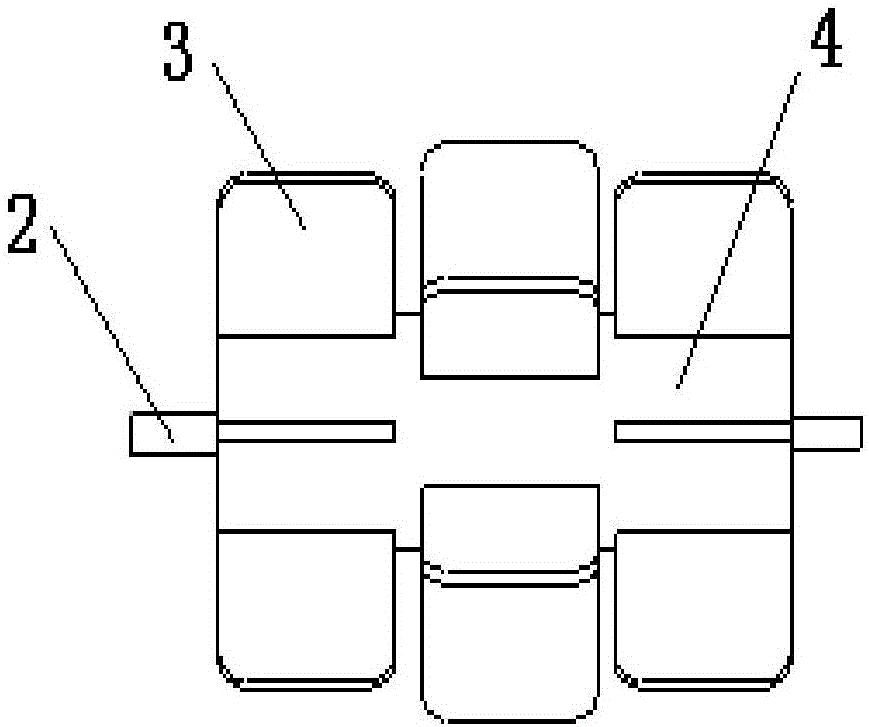

[0021] see Figure 1-Figure 4 , a kind of novel mixing machine that is applicable to rubbish material of the present invention, comprises feed port 6, casing 5, mixing roller, driving device 1 and frame (not shown), and mixing material is housed in casing 5 Roller, the end shaft 2 at one end of the mixing roller is in transmission connection with the driving device 1, and the top and bottom ends of the box body 5 are respectively provided with a material inlet 6 and a material outlet 7.

[0022] Described mixing roller is provided with at least two groups; In some preferred embodiments of the present invention, described mixing roller is provided with two groups, is respectively arranged on the upper part and the lower part of casing 5, upper and lower mixing roller The axial directions of the material rollers are the same and misplaced with each other, and the end shafts 2 of the two are connected by a transmission mechanism (such as a chain transmission, a gear transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com