Connection system for axially securing a shaft-hub connection and method for axially securing a shaft-hub connection

A technology of axial fixation and connection system, which is applied in the direction of connection components, connections, rigid shaft couplings, etc., can solve the problems of increasing the quality of the connection system, and achieve the effects of simplified manufacturing, simple structure, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

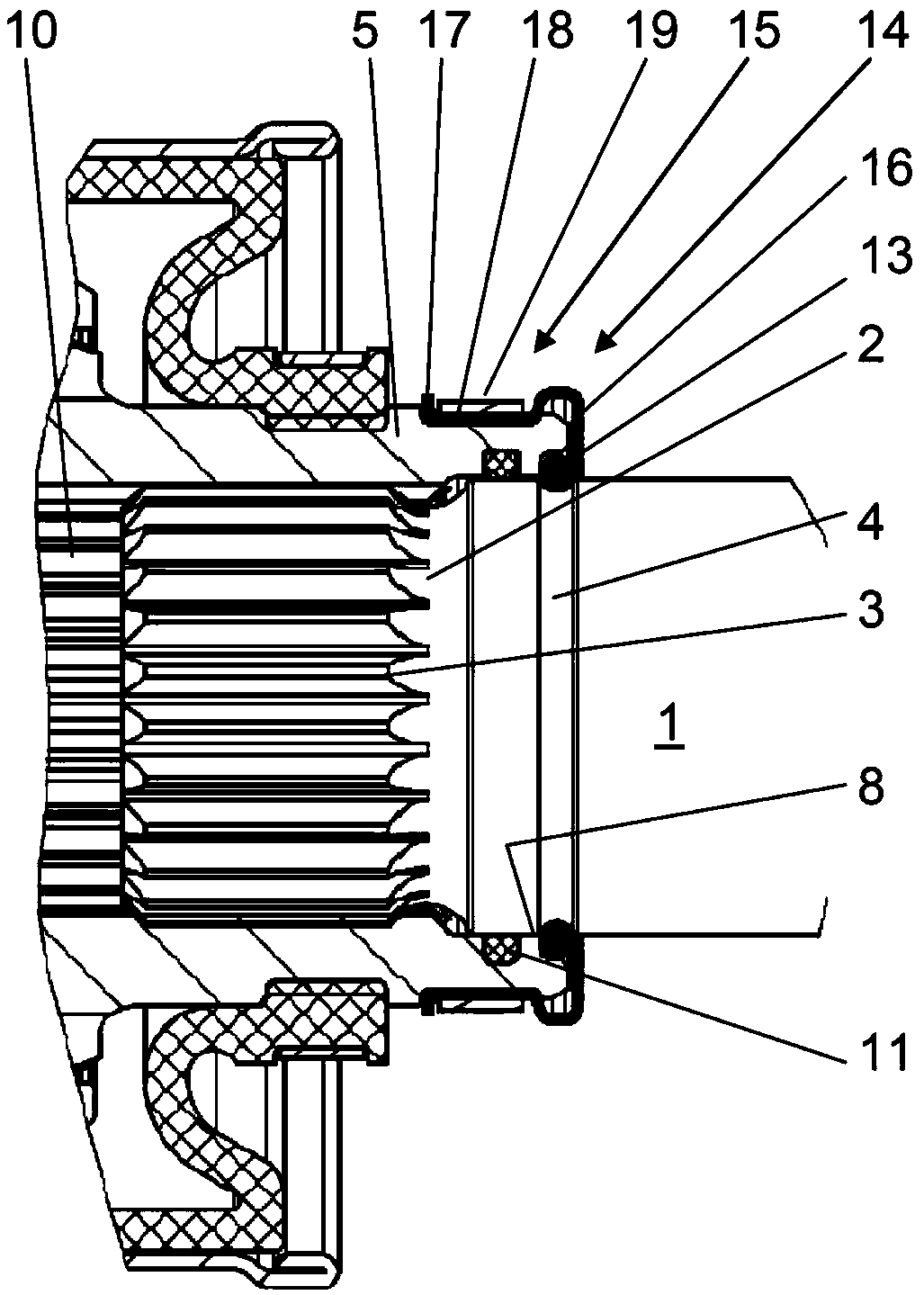

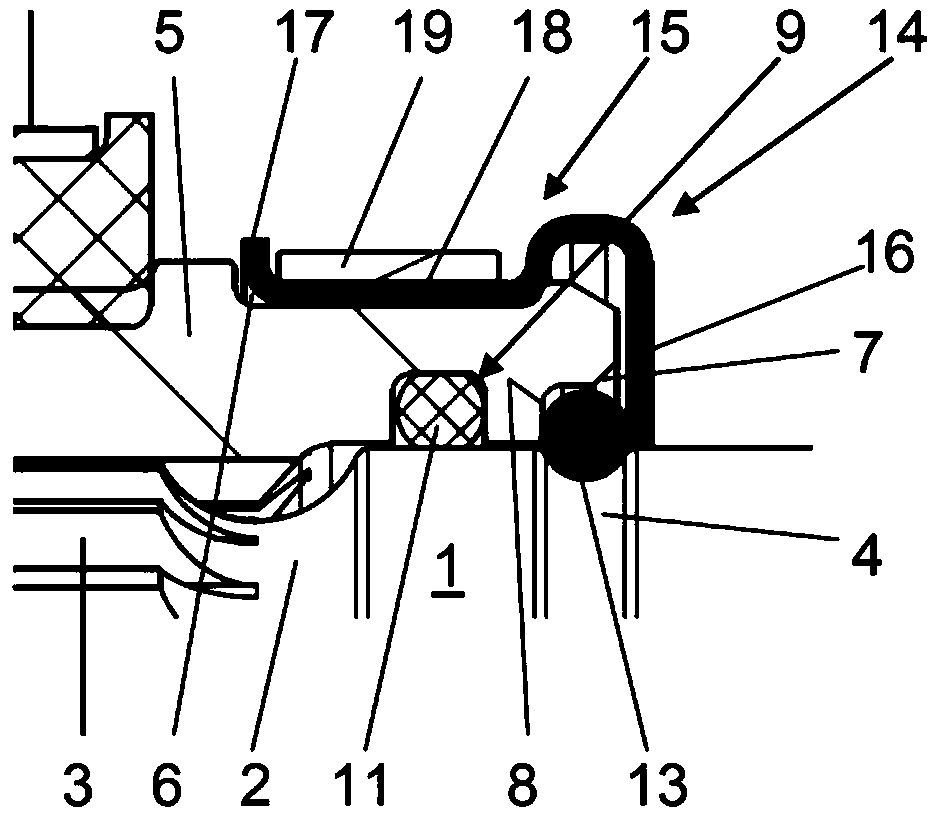

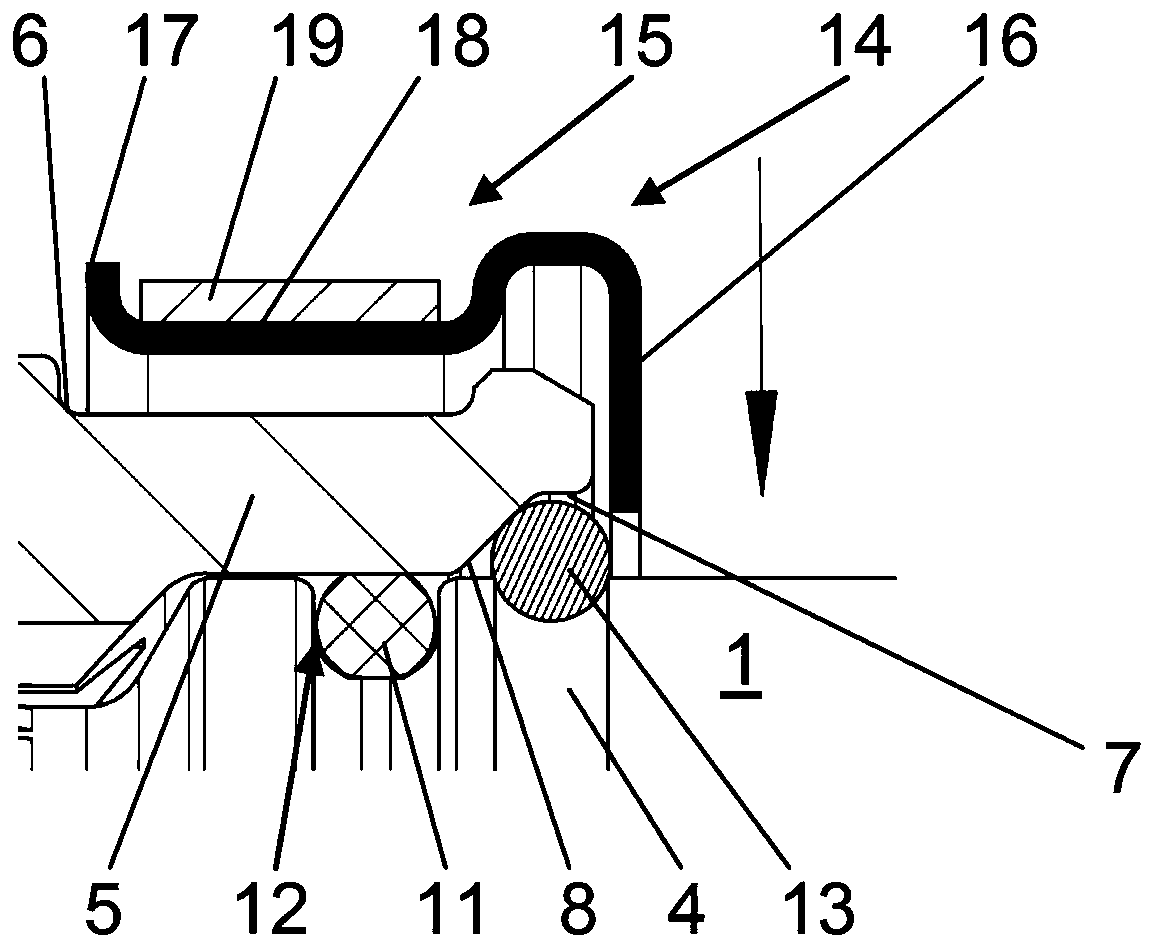

[0045] figure 1 shows the principle of the connection system according to the invention for axially securing the shaft-sleeve connection in the assembled state, while figure 2 An enlarged view showing a detail of the connection system. Said connection system comprises a shaft 1 and a bushing 5, said shaft having on one end thereof a journal 2 with external splines 3 and provided with a groove 4 at a short axial distance from the journal, In the present exemplary embodiment, the bushing is designed as the inner ring of the joint. The bushing 5 has a widened outer groove 6 on its outer circumference and a notch 7 on its end face facing the shaft 1, said notch 7 having a larger diameter than the inner diameter of the bushing so that behind its end face The axial stop surface 8 is formed at the shorter axial distance. The inner diameter of the bushing 5 axially adjoining the recess 7 corresponds to the outer diameter of the shaft 1, where the two diameters form a fit with each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com