Modal parameter test method of rigid body of power assembly suspension system based on full-automobile states

A powertrain and rigid body modal technology, which is applied to vehicle suspension/shock absorber testing and other directions, can solve the problems of non-simultaneous acquisition of frequency response function data, loss of modal identification, and irrelevance of frequency response function consistency. Avoids irrelevant effects of FRF consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the present invention will be described in detail by taking the power assembly of the three-point suspension system as an example, with reference to the accompanying drawings and specific embodiments.

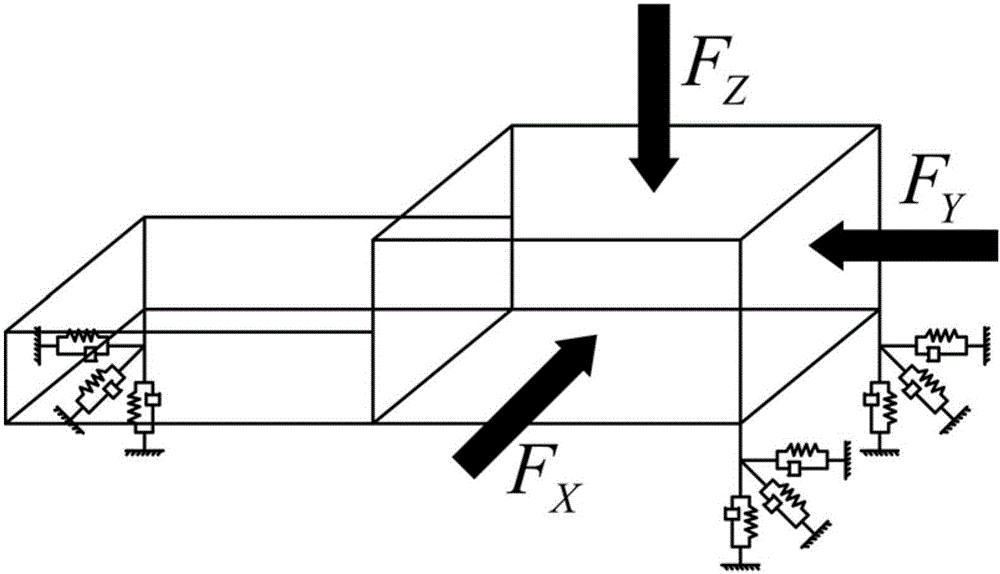

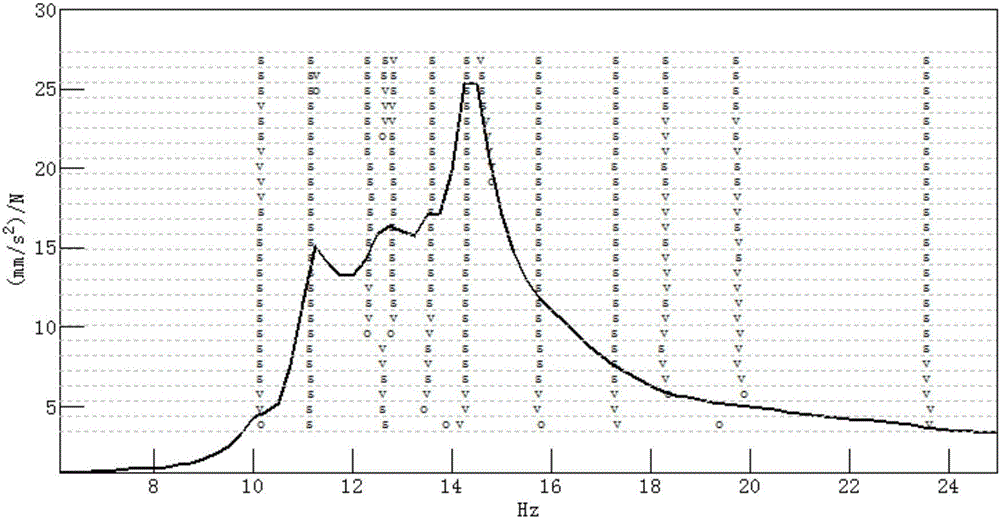

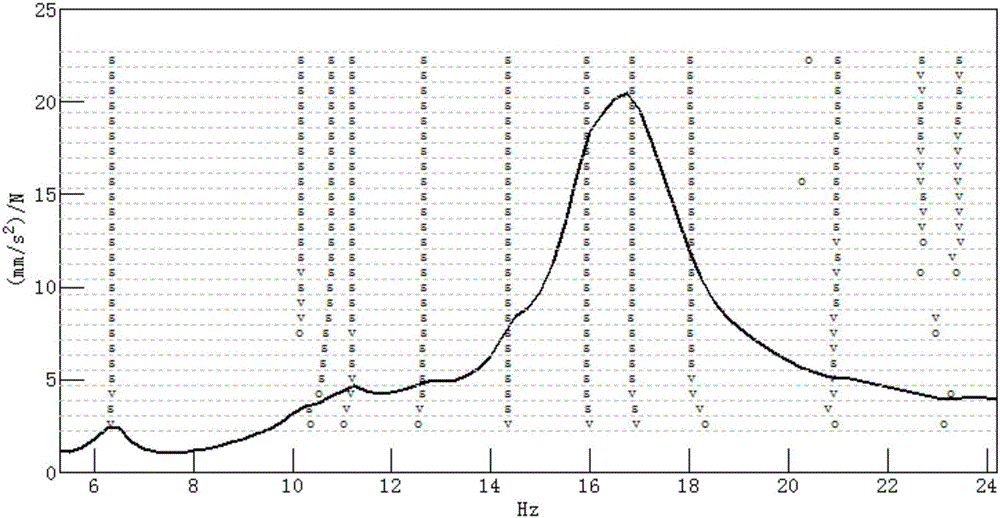

[0034] A test method for the rigid body modal parameters of the powertrain suspension system in the vehicle state. The test method is to use the rubber soft hammer head of the counterweight as the hammer excitation, and take the direction of the vehicle coordinate system as the reference: the X axis points to the rear of the vehicle Perpendicular to the front axis, the Z axis is vertically upward, and the Y axis is determined according to the right-hand rule; figure 1 As shown, taking the powertrain of the three-point suspension system as an example, the six free rigid body modes (translation in three directions and rotation in three directions) are divided into three groups, and each group is subjected to a separate modal parameter Identification; the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com