An automatic folding and recycling device for the coaming box of automobile exterior parts

A technology for recycling equipment and coaming boxes is applied in the field of automatic folding and recycling equipment, which can solve the problems of time-consuming and laborious work efficiency, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

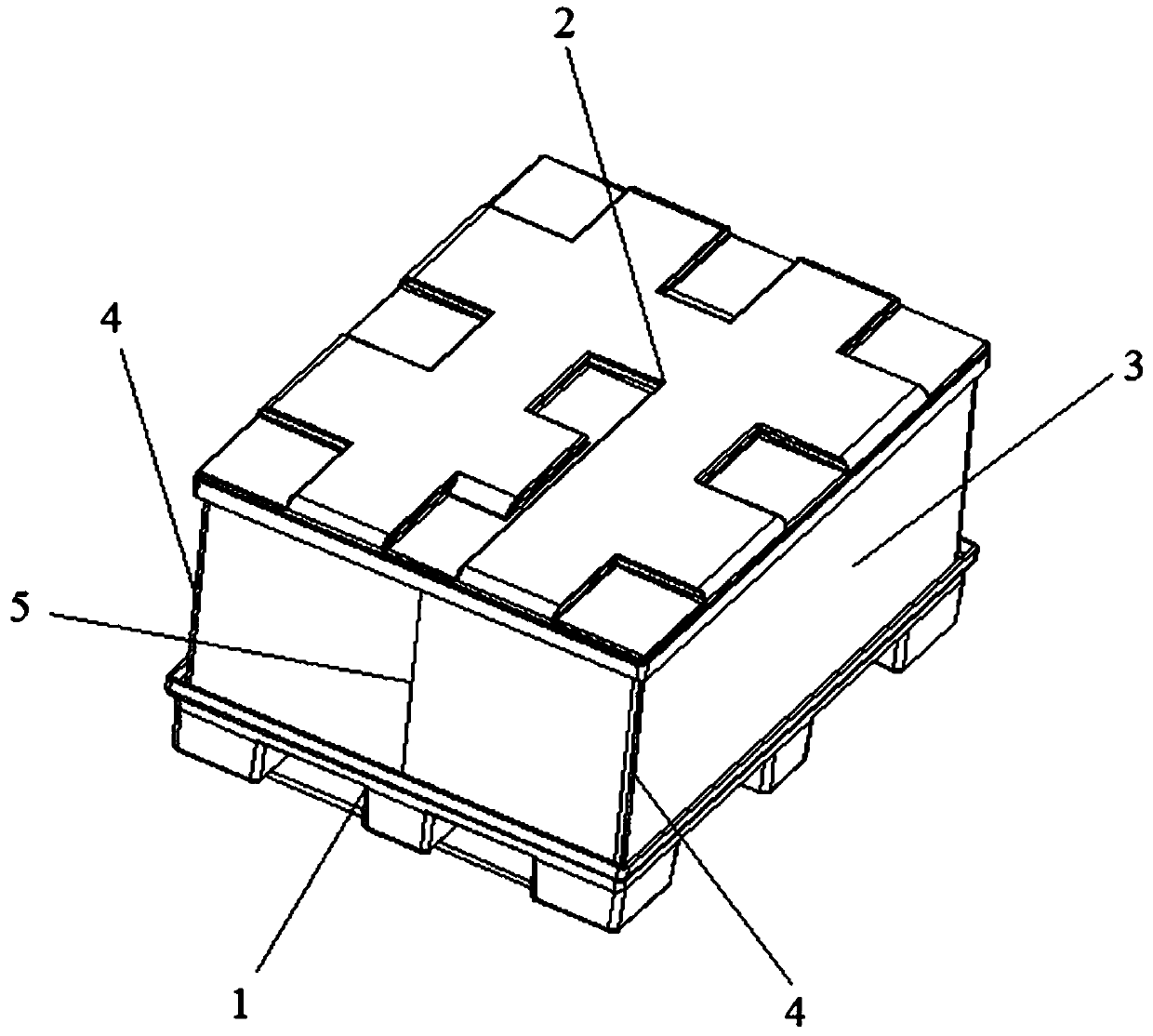

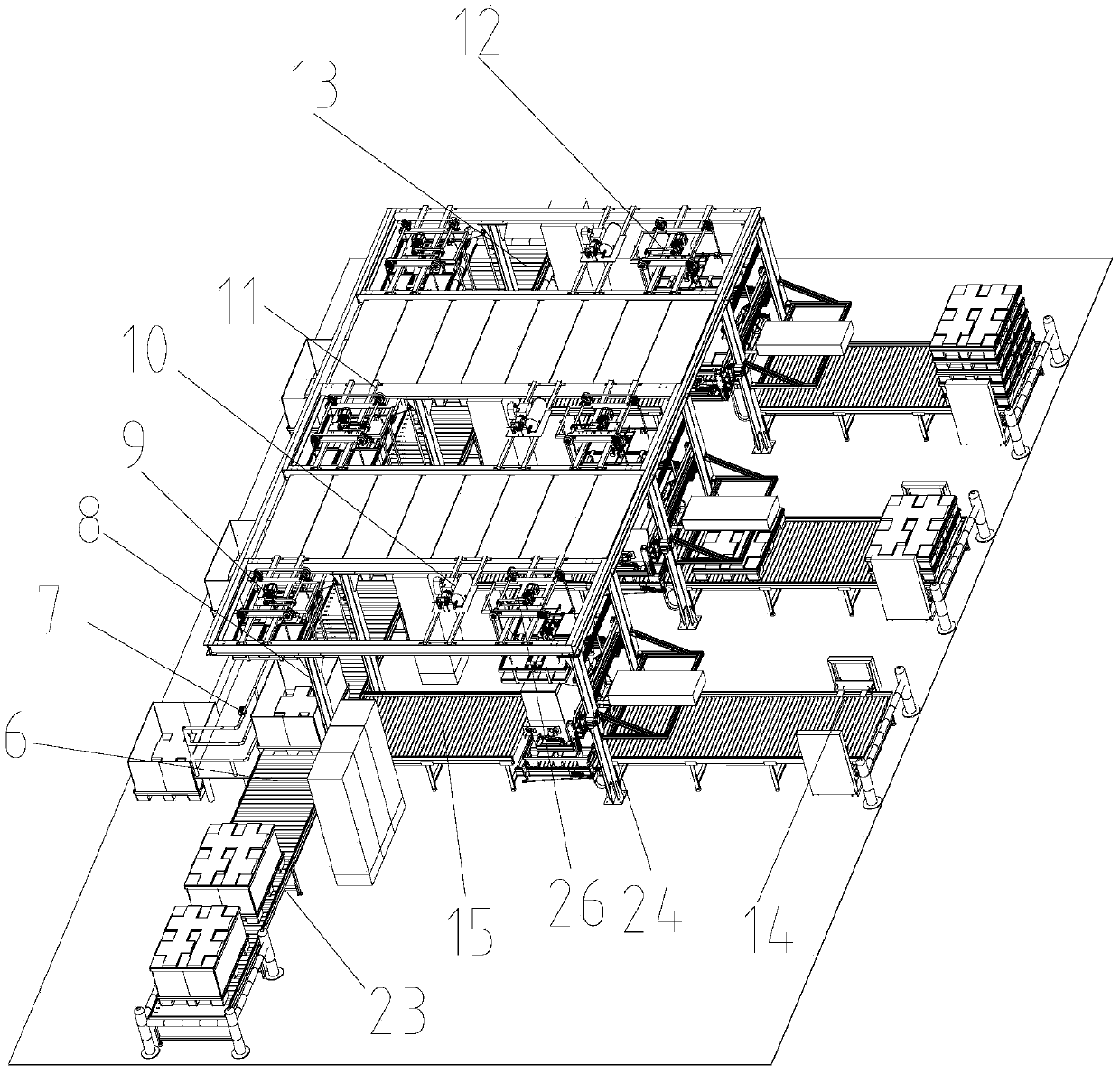

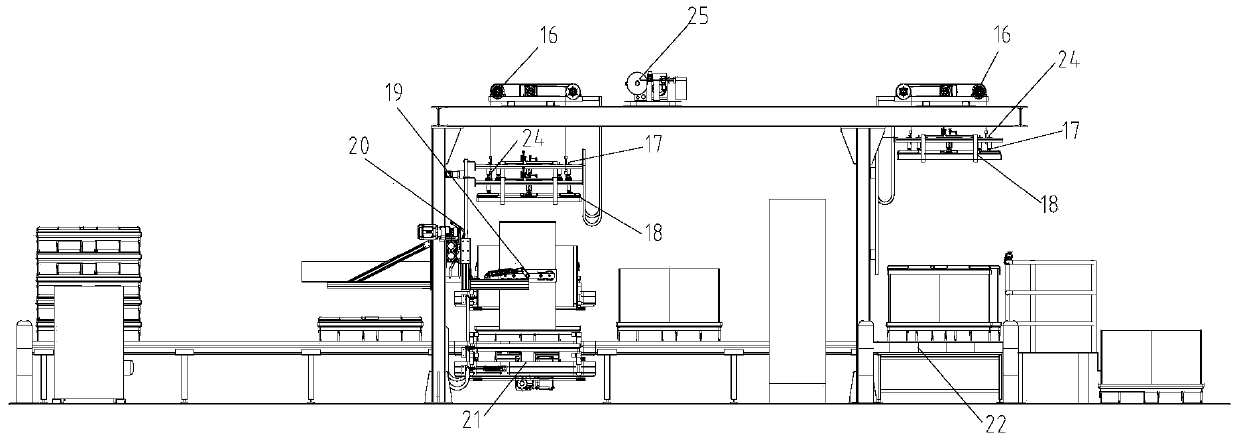

[0028] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown in the figure, an automatic folding and recycling equipment for the coaming box of the automobile exterior trim includes a roller bed conveying device 6, a box automatic identification device 8, a steel structure bearing device 11, a first box cover suction and lifting device 9, a rotating The folding device 12 , the second case cover suction and lifting device 26 and the stacking and collecting device 14 . Wherein the roller bed conveying device 6 comprises a main line roller bed 13 and three branch line roller beds 15 vertically connected thereto, and the connection between the main line roller bed 13 and the branch line roller beds 15 is provided with a coaming box from the main line roller bed 13 to the branch line rollers. Mainline roller bed transitions from bed 15 to conveyor 22 and block stops for positioning coaming boxes. The roller bed conveying device 6 also includes a casing running track gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com