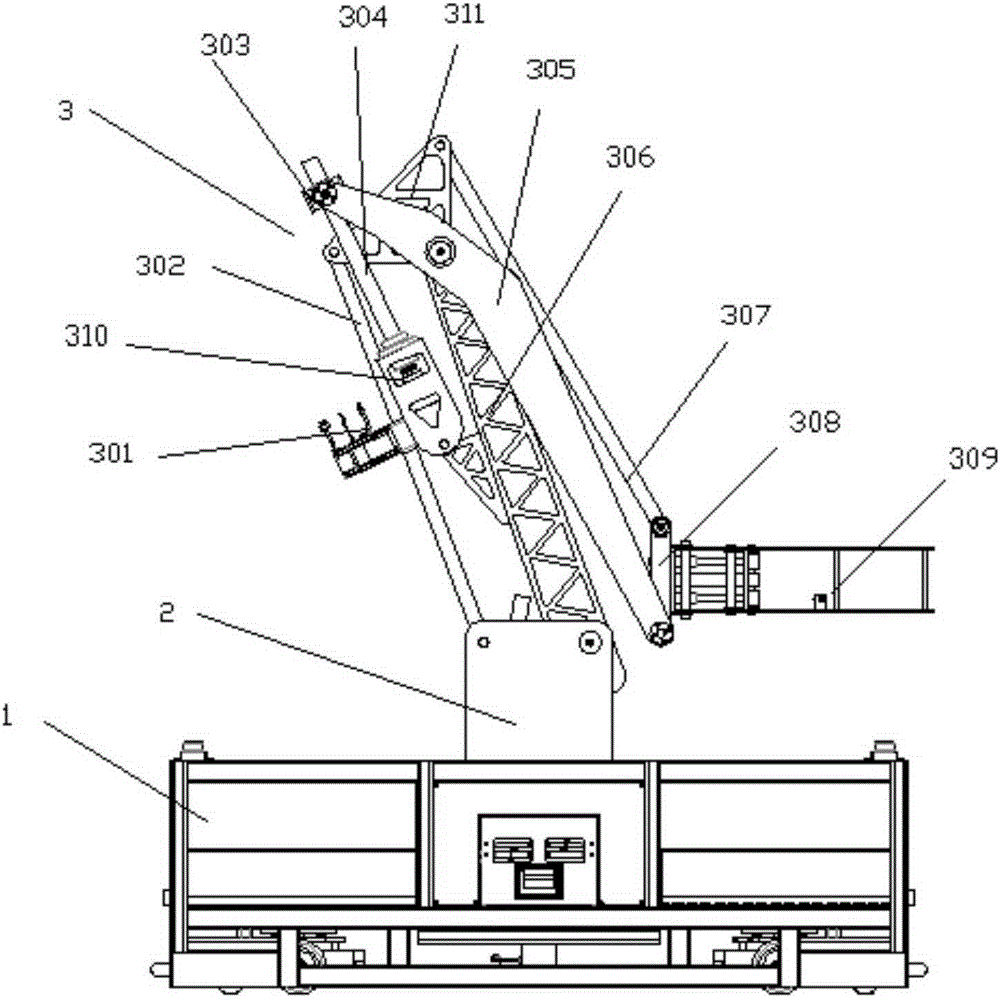

Vehicle-mounted cotton spinning mechanical arm

A manipulator, cotton textile technology, applied in the field of robots, can solve the problems of inconvenient transportation of textile products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0023] like figure 1 As shown, a vehicle-mounted cotton textile manipulator, the AGV car 1 is provided with a turntable slewing bearing, the turntable slewing bearing includes a slewing bearing and a turntable, the center line of the slewing bearing is vertically arranged, and the turntable of the turntable slewing bearing A support seat 2 is fixed on it. In this embodiment, the turntable type slewing bearing is arranged in the middle part of the AGV vehicle, and the driving shaft of the turntable type slewing bearing is connected to a second motor. The second motor communicates with the battery of the AGV vehicle. The battery of the car provides power to the second motor to drive the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com