rotating electrical machine

A technology for rotating motors and rotors, which is applied to electrical components, electromechanical devices, and electric components. It can solve problems such as increased workload, shedding of balance weights, and increased corrections, and achieve the effect of preventing accidental movement of keys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

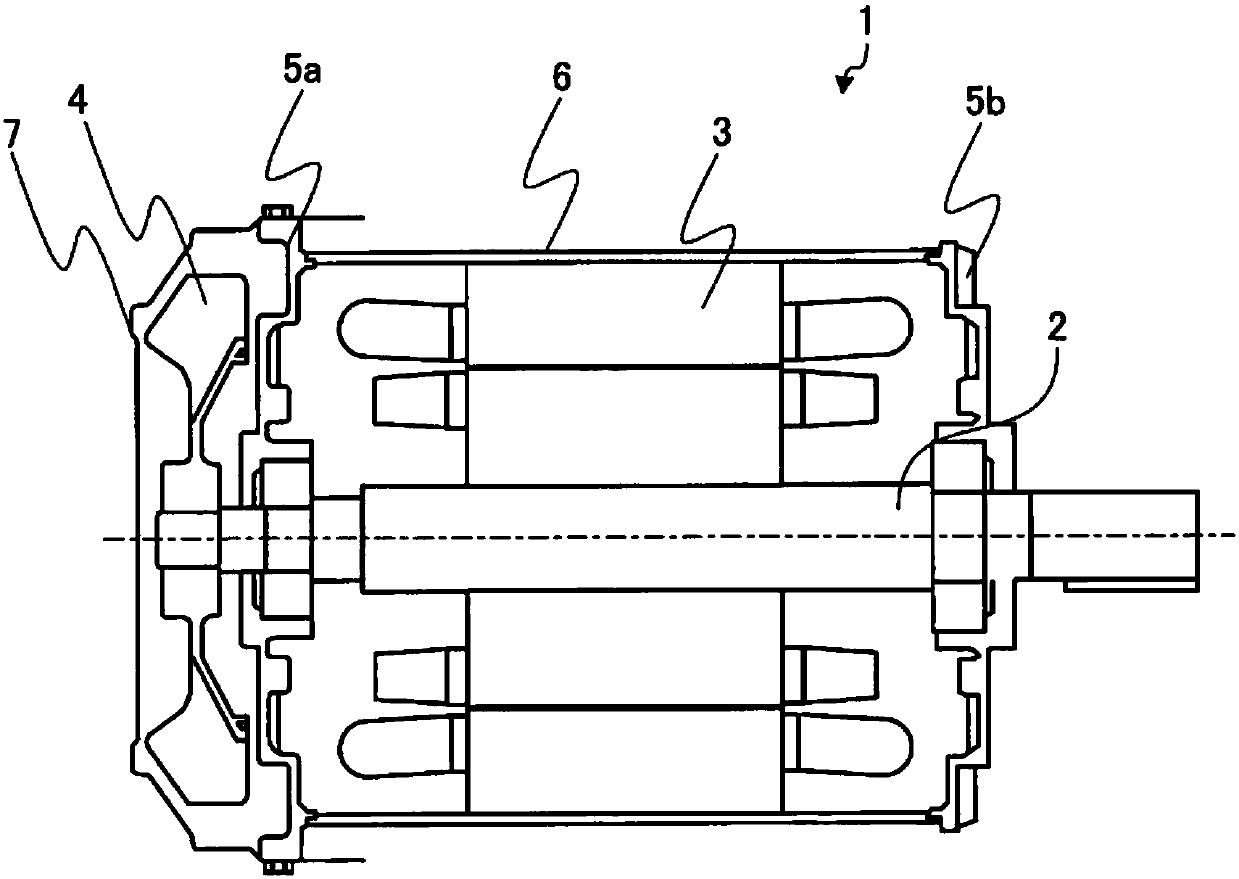

[0056] figure 1It is a figure which shows the cross-sectional shape of Embodiment 1 of the rotating electric machine concerning this invention. The rotating electrical machine 1 is composed of a rotor 2 and a stator 3 , and an external fan 4 is attached to one side of the rotor 2 for cooling the heat generated by the rotating electrical machine 1 . Brackets 5 a and 5 b and a frame 6 are attached to the outside of the stator 3 , and a fan cover 7 is attached to the outside of the external fan 4 .

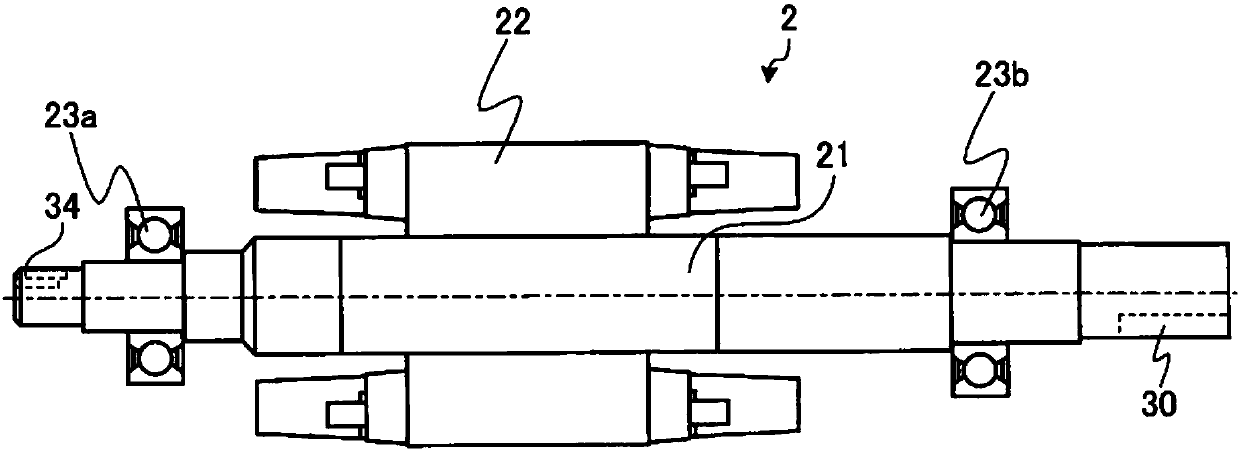

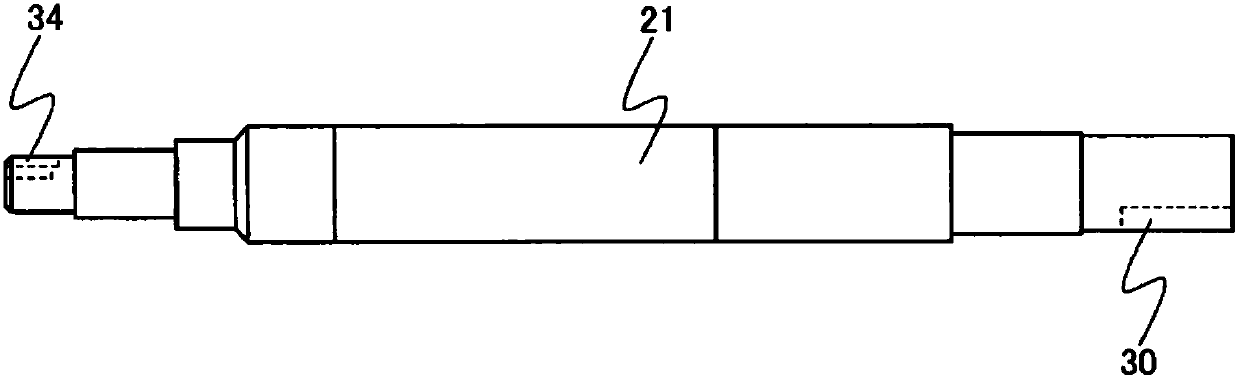

[0057] figure 2 It is a figure which shows the structure of a rotor. The rotor 2 is constructed such that a shaft 21 passes through the center of an iron core 22, and they are held by bearings 23a, 23b. image 3 It is a figure showing the structure of the shaft. On the P side of the shaft 21, a key groove 30 for inserting a key for coupling with a coupling or a mechanical device is engraved. In addition, on the O side of the shaft 21, a key groove 34 into which a key for coupli...

Embodiment approach 2

[0077]Regarding Embodiment 1, in the step of machining the key groove of the shaft, two key grooves having different widths must be produced. For this reason, it is necessary to prepare tools with different sizes when milling the key groove, and the complexity of the work increases. In Embodiment 2, a method realized by using grooves of the same width will be described.

[0078] Figure 29 , Figure 30 as well as Figure 31 It is an enlarged view of the end portion of the shaft on the O side of Embodiment 2 of the rotating electric machine according to the present invention, Figure 29 for top view, Figure 30 main view, Figure 31 for side view. The key groove 36 has a shape in which, in addition to the shallow groove 361 having a first depth as a key fitting groove, it has the same width as the shallow groove 361 and a second depth deeper than the first depth as a balance adjustment. The groove is provided with a deep groove 362 . The depth of the key groove 36 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com