Air knife width variable device with excellent operating efficiency

A technology of operating efficiency and air knife, applied in metal material coating process, hot-dip plating process, coating, etc., can solve vibration and noise, multiple circular tubes with different diameters, and unable to accurately adjust the range of high-pressure gas injection, etc. problem, to achieve the effect of improving blocking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

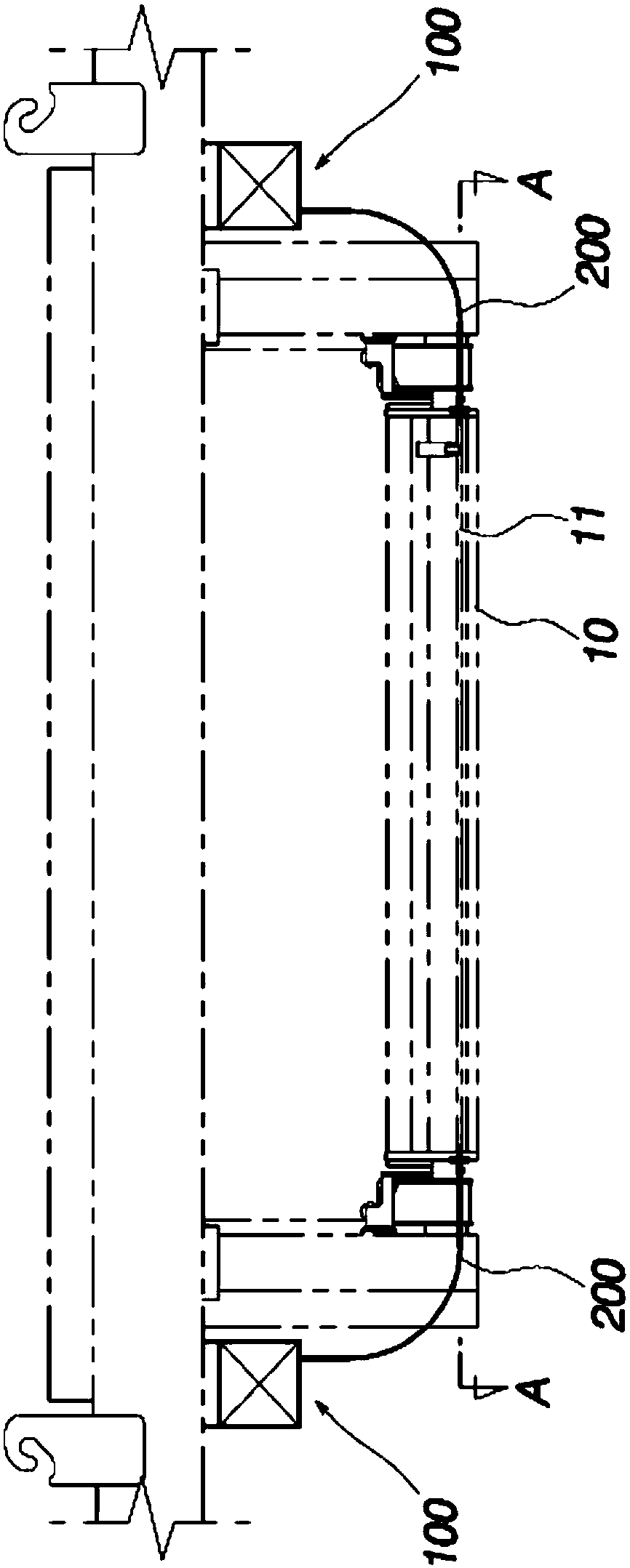

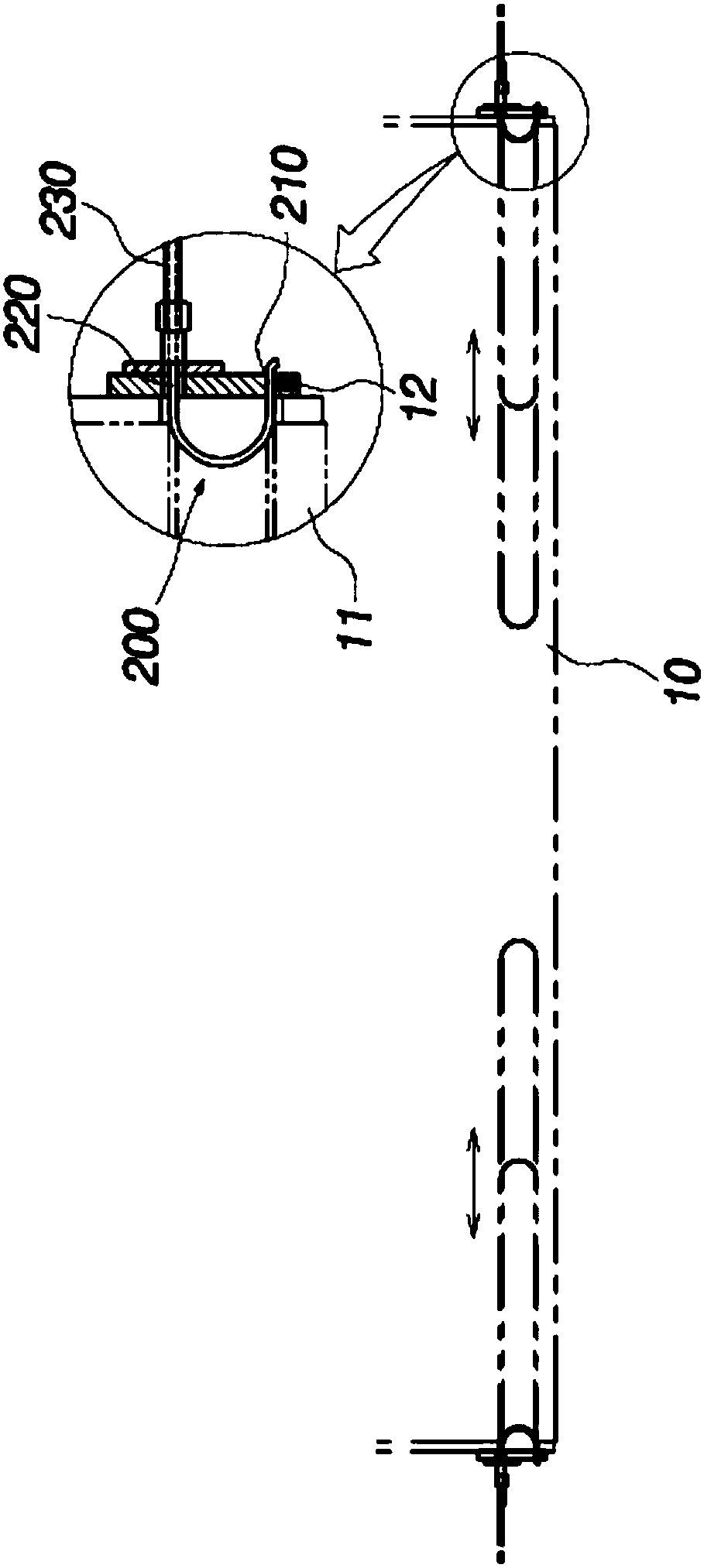

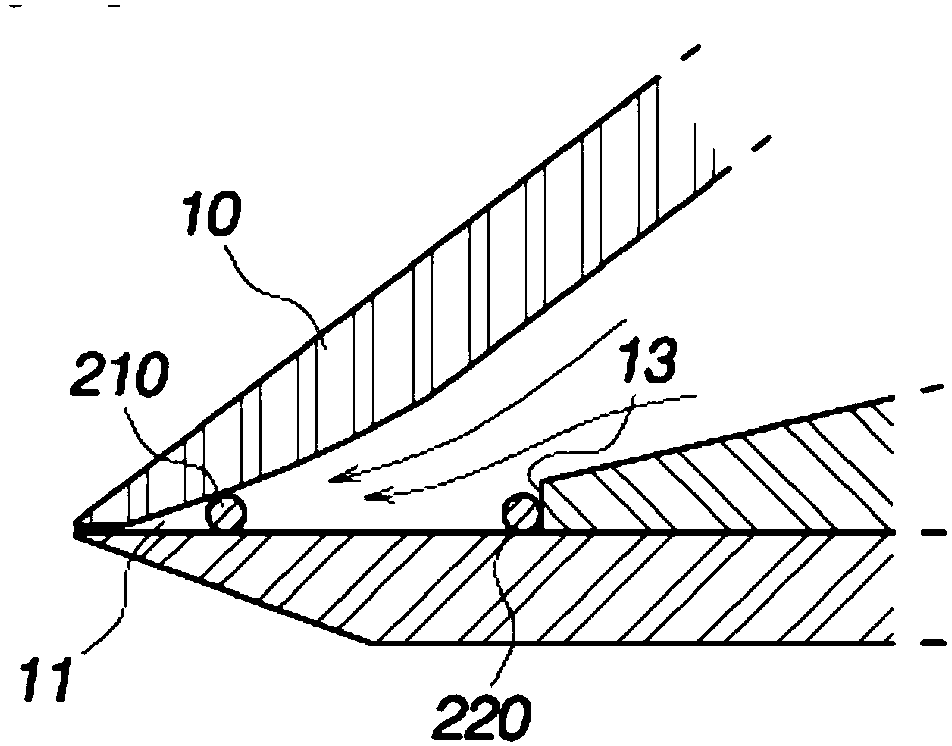

[0038] figure 1 It is a front view showing the structure of the air knife width variable device excellent in operating efficiency according to the present invention; figure 2 yes figure 1 A-A line profile; image 3 and Figure 4 is a sectional view for showing the operating state of the blocking member in the present invention; Figure 5 is a perspective view for illustrating the structure of the driving part in the present invention; Figure 6 is a front view for showing the structure of the driving part in the present invention; Figure 7 is a rear view for showing the structure of the driving part in the present invention; Figure 8 It is a reference figure for showing the structure of the position setting means in this invention.

[0039] The present invention is, according to the variable width device of the air knife composed of the driving part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com