Sliding assembly

A technology of sliding components and sliding elements, which is applied in the direction of furniture parts, furniture accessories, lighting and heating equipment, etc., and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

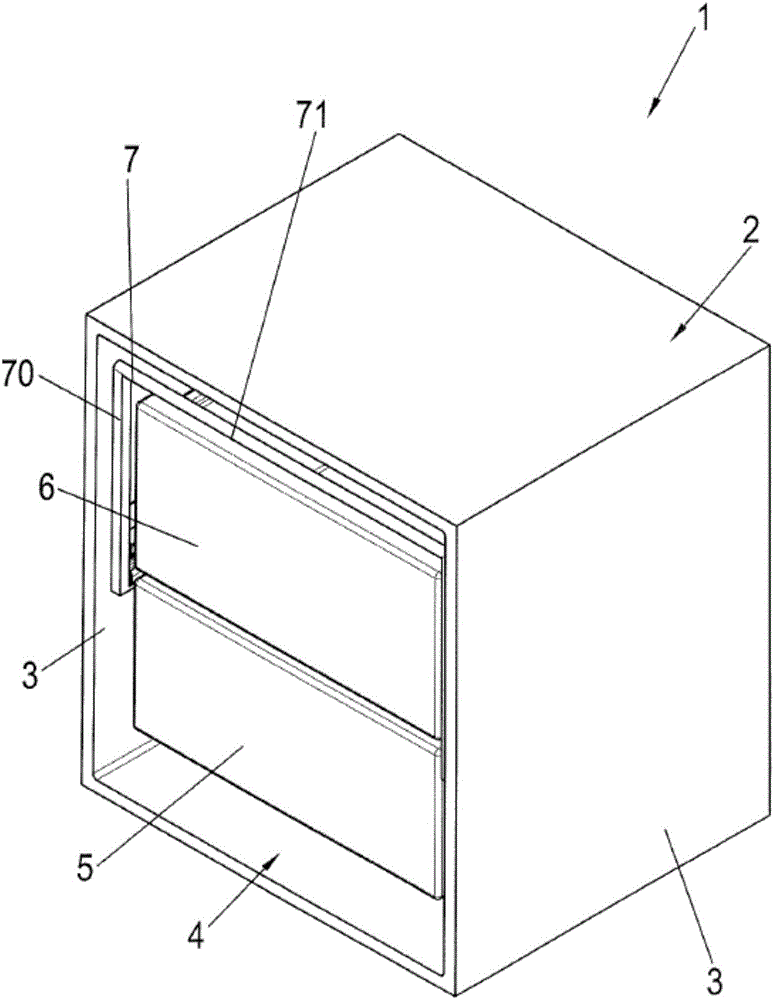

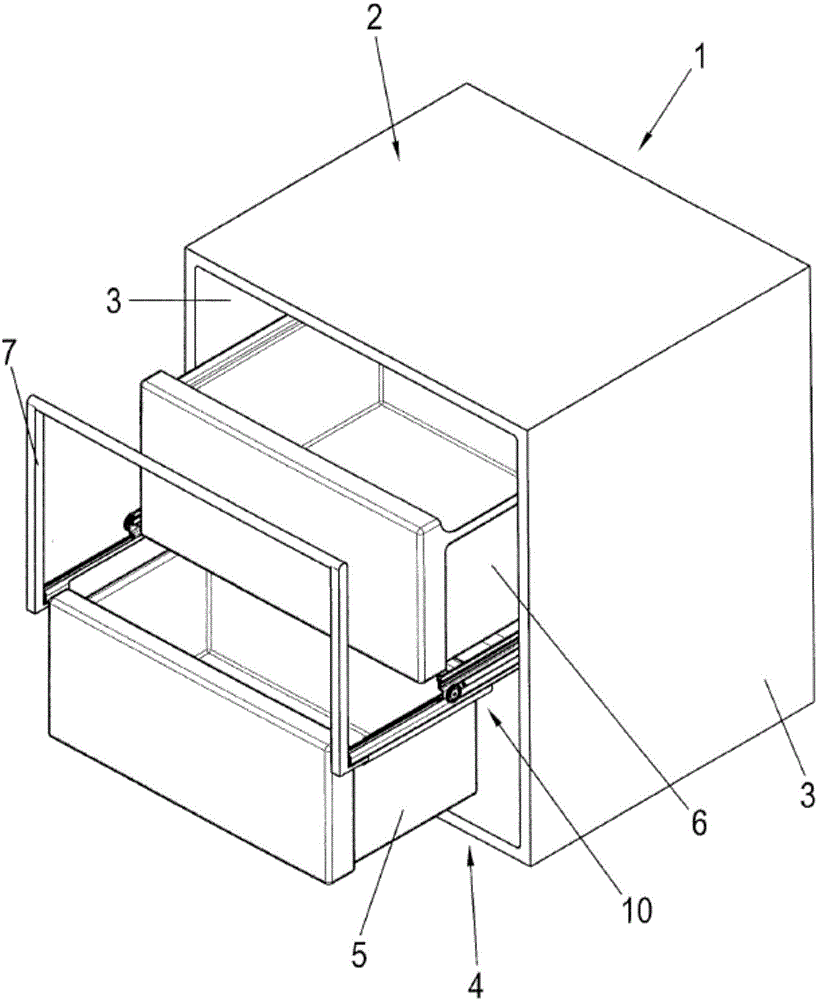

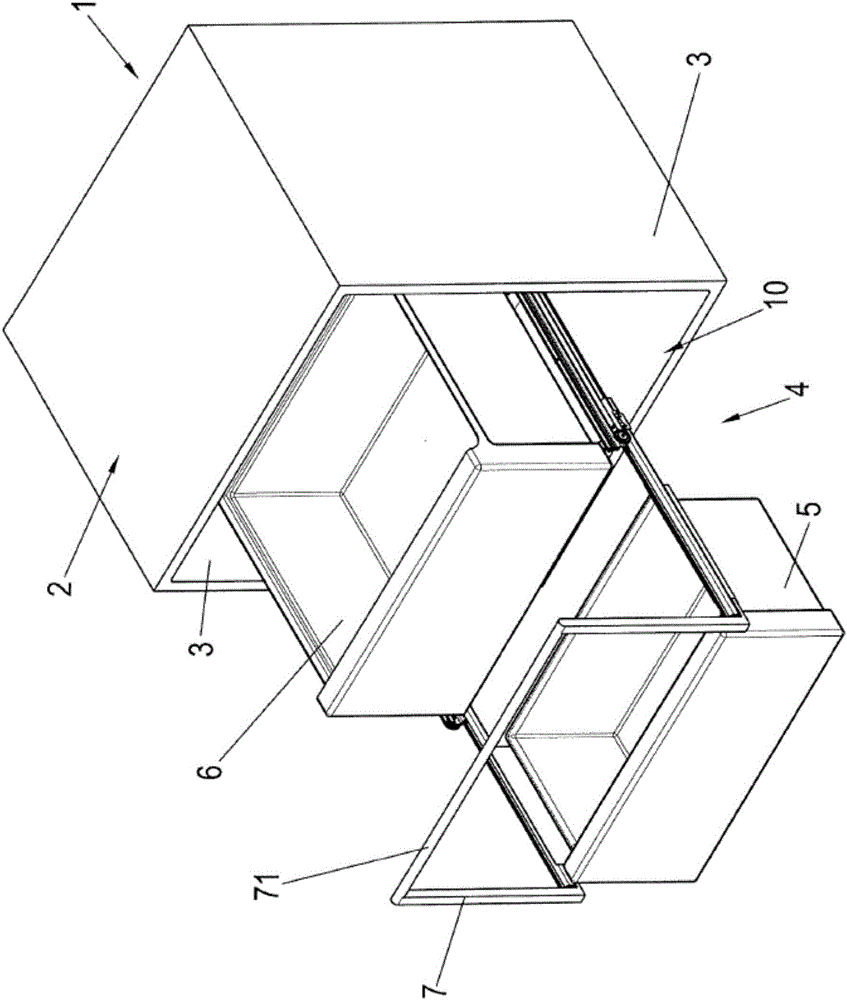

[0023] A piece of furniture or a household appliance 1 comprises a furniture body 2 , for example the body of a refrigerator or a cold room of a refrigerator-freezer combination, which body 2 includes two side walls 3 on which a sliding assembly 4 is mounted. The slide assembly 4 can be mounted on the side wall 3 directly or via additional fastening elements.

[0024] The slide assembly 4 comprises a bottom first slide element 5 and an upper second slide element 6, both of which are formed as drawers and are used to store items such as food. Arranged on the bottom sliding element 5 is an actuating element 7 which is formed as a U-shaped bracket and comprises two vertical struts 70 and a connecting element 71 which is arranged in front of the upper sliding element 6 in the closed position. side above. Thus, the connecting element 71 can be easily grasped to move the slide assembly from the closed position to the open position.

[0025] figure 2 The slide assembly 4 is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com