Pressure touch screen and display device

A touch screen and pressure technology, which is applied to the input/output process of instruments, electrical digital data processing, data processing, etc., can solve the problems of low assembly yield and difficult assembly operations, and improve assembly yield and assembly accuracy. Low requirements and the effect of reducing the difficulty of assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

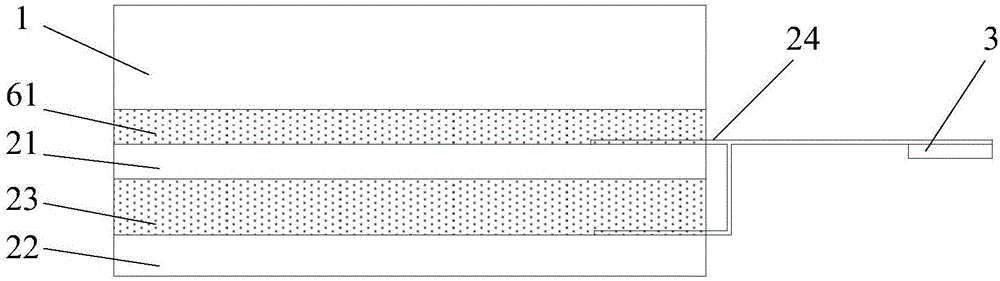

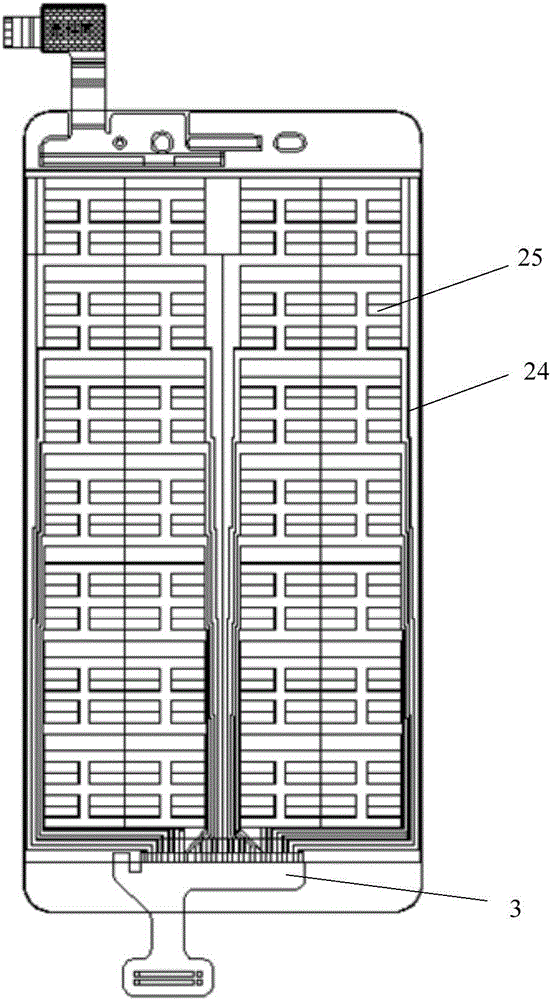

Embodiment 1

[0032] Such as Figure 1-4 As shown, the pressure touch screen provided by the embodiment of the present invention includes: a touch layer 1 and a pressure sensing detection device, the pressure sensing detection device is disposed on the light incident side of the touch layer 1, and the light incident side of the touch layer 1 is disposed There is a pressure sensing detection device, the pressure sensing detection device includes: a first electrode layer 21, a second electrode layer 22 and a flexible spacer layer 23, the first electrode layer 21 is bonded to the touch layer 1, the first electrode layer 21 and the second electrode layer The two electrode layers 22 are arranged oppositely, the flexible spacer layer 23 is located between the first electrode layer 21 and the second electrode layer 22, the hardness of the first electrode layer 21 is smaller than the hardness of the second electrode layer 22, the first electrode layer 21 and the second electrode layer 22 Since the ...

Embodiment 2

[0045] Such as Figure 1-4 As shown, Embodiment 2 of the present invention provides a display device, including the pressure touch screen provided in Embodiment 1 above.

[0046] Specifically, the pressure touch screen is arranged between the cover plate 4 and the color filter 5, and other functions are also arranged between the pressure touch screen and the cover plate 4, and between the pressure touch screen and the color filter 5. Layer 6 will not be repeated here. The pressure touch screen includes a touch layer 1 and a pressure detection device. The pressure detection device includes a touch layer 1, a first electrode layer 21, a flexible spacer layer 23 and a second electrode layer 22. The touch layer 1 is arranged near the cover plate 4, the pressure detection device is arranged on the side close to the color filter 5, the first electrode layer 21 is bonded to the side of the touch layer 1 close to the color filter 5 through an optically transparent adhesive, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com