Flexible parallel drive device for ship propeller swing and rotation

A driving device and propeller technology, which is applied in propulsion transmission devices, ship propulsion, ship parts, etc., can solve the problems such as complexity, complexity and failure of the rudder drive mechanism and rudder control system, and achieve small vibration, easy control, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

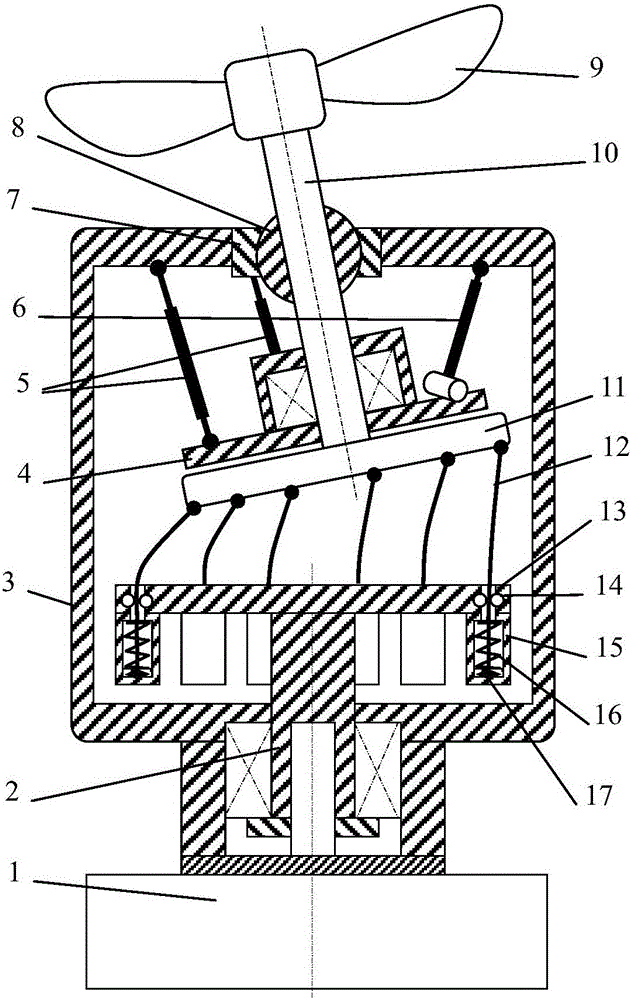

[0015] exist figure 1 In the schematic diagram of the ship propeller oscillating flexible parallel driving device shown, the base 3 is a cylindrical cavity, and the upper and lower ends of the base cylinder are provided with coaxial through holes; In the cylindrical cavity of the seat; two SPS-type drive branches 5 and one SPR-type drive branch 6 with the same structure are evenly distributed on the circumference between the upper end of the base and the moving table 4; the SPS-type drive branch is a conventional linear hydraulic drive cylinder, Its two ends are respectively connected with the upper end of the machine base and the moving billiard ball pair. The SPR type drive branch is a conventional linear hydraulic drive cylinder, one end of which is connected with the ball pair at the upper end of the machine base, and the other end is connected with the rotating pair tangential to the circumference of the moving table. ; The ball seat 7 of the middle SP-type restraint bran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap