Flexible explosion-proof joint box and production method thereof

A joint box, flexible technology, applied in the direction of cable joints, etc., can solve the problems of complicated materials, unsatisfactory insulation performance of flexible bellows, and thick coating layer, so as to reduce the probability of accidents, facilitate normal inspection, and facilitate installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

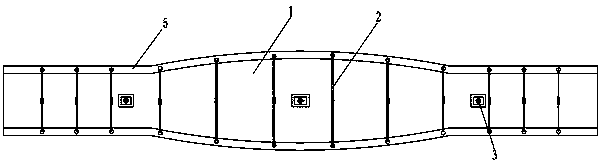

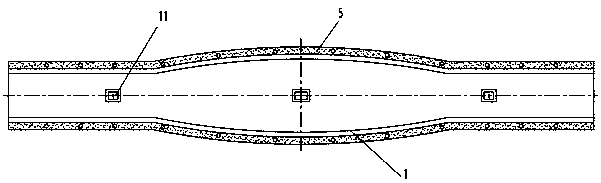

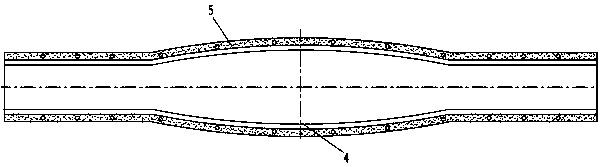

[0020] Such as Figure 1 to Figure 4 As shown, a flexible explosion-proof joint box includes an upper box cover 1 and a lower box cover 4 that are detachably connected, and both the upper box cover 1 and the lower box cover 4 have an arc that bulges outward in the middle Structure, the upper box cover 1 and the lower box cover 4 are buckled along the axis of the cable 7, and the arc-shaped structure is formed to wrap the cable 7 after the upper box 1 cover and the lower box cover 4 are buckled Space for joints.

[0021] In the above embodiment, the flexible explosion-proof joint box has the characteristics of flexibility, fire prevention, arc extinguishing, pressure relief, flame retardancy, etc., is easy to install, and has functions such as tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com