Site-clearing float device used for liquid surface volatile gas detectors

A technology for volatile gas and detectors, which is applied in the field of clearing and floating devices for liquid surface volatile gas detectors, which can solve the problems of sampling failure and the difficulty of completely covering the water surface with a closed gas chamber structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

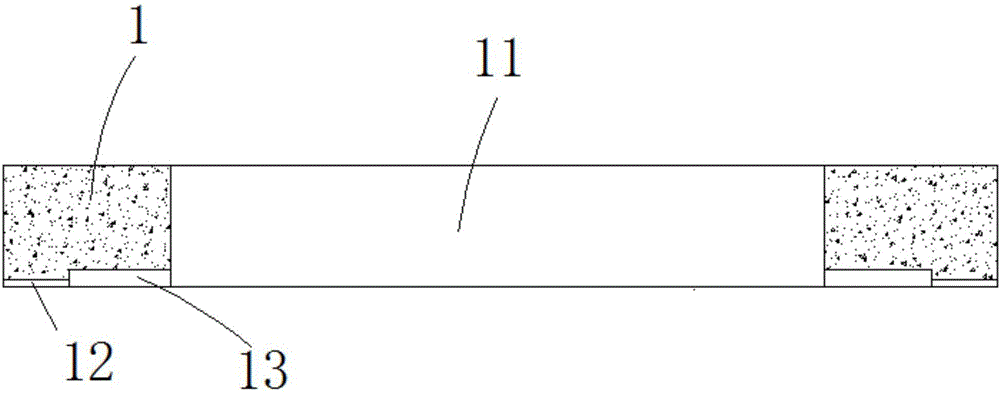

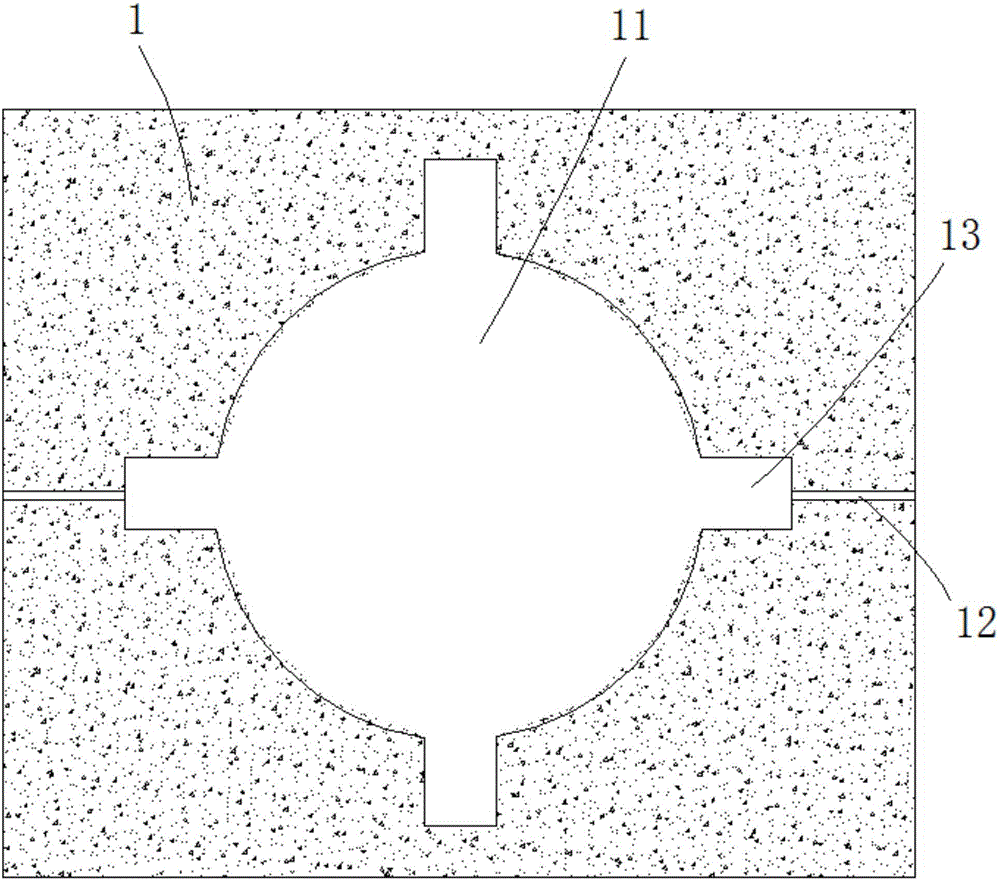

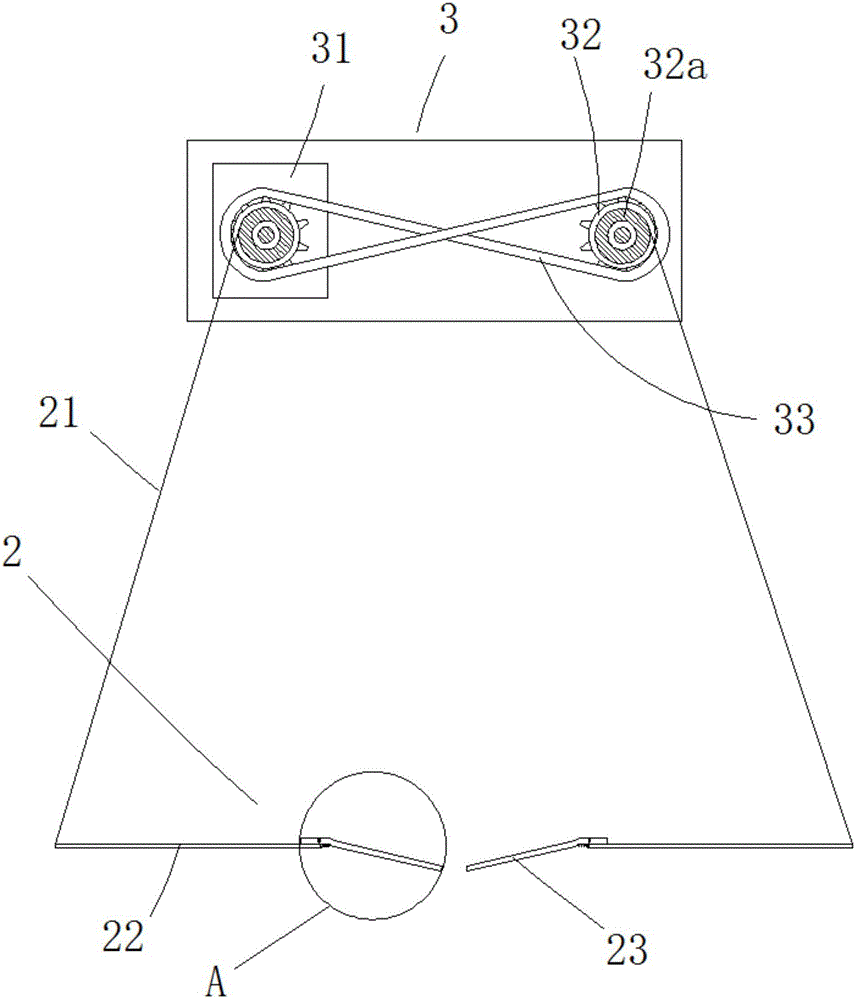

[0025] A clearing and floating device for a liquid level volatile gas detector according to the present invention, which includes a floating plate 1, two symmetrically arranged two clearing structures 2 and a clearing motor device 3, and the floating plate 1 is provided with a through cavity 11 that penetrates up and down The lower surface of the floating plate 1 is provided with two left and right damping grooves 12, and the field clearing motor device 3 includes a field clearing motor 31, two transmission gears 32 and a transmission chain 33 that is 8-shaped around the two transmission gears 32, and the field clearing motor 31 and One of the transmission gears 32 is transmission connected, and each transmission gear 32 is provided with a winding groove 32a, and the winding groove 32a is coaxially arranged with the gear shaft of the transmission gear 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com