Energy-saving hot freon drying and dehumidification system and control method thereof

A ventilation system and control device technology, applied in the direction of control/regulation system, drying, drying machine, etc., can solve the problems of high energy consumption, waste of resources, drying pollution, etc., to expand the use conditions, reduce economic costs, The effect of improving the energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

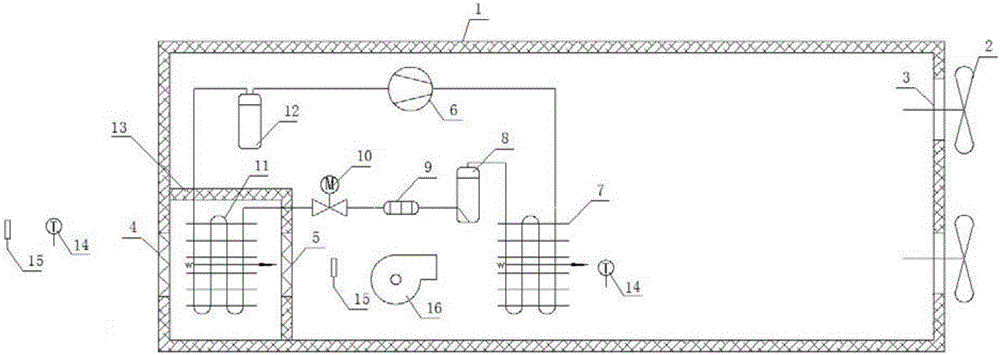

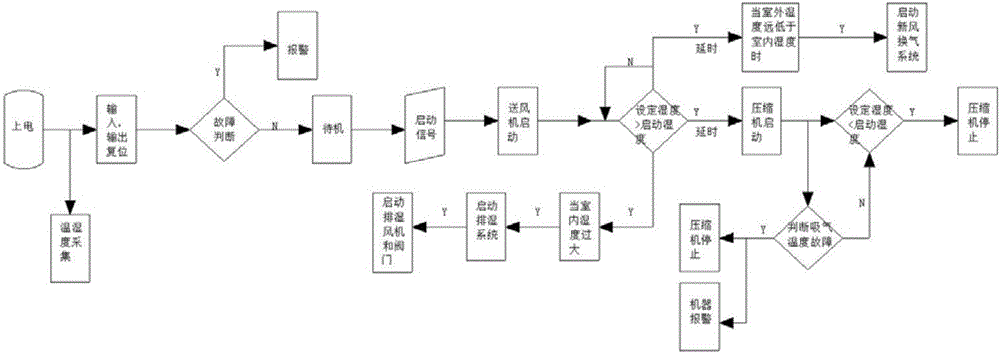

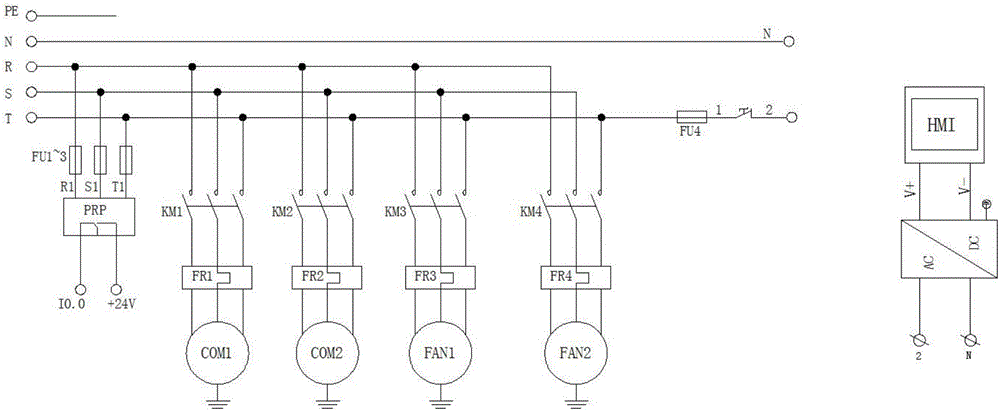

[0023] Such as figure 1 As shown, the present invention is realized in such a way that the hot fluorine drying and dehumidification system includes a drying and dehumidification chamber 1, and its structural feature is that it also includes a hot fluorine drying and dehumidification unit arranged in the drying and dehumidification chamber 1 and fresh air The ventilation system and the dehumidification system, the hot fluorine drying and dehumidification unit, the fresh air ventilation system and the dehumidification system are all connected to the control device, and the control device is respectively connected to the temperature sensor 14 and the humidity sensor located inside and outside the drying and dehumidification chamber 1. The sensor 15 is electrically connected; the present invention can realize the coordinated and integrated opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com