A high-pressure fuel rail assembly for an engine

A high-pressure oil and engine technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of fast fuel heating and heating, slow fuel heating, affecting the effect of fuel atomization, etc. Compact structure and fast start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

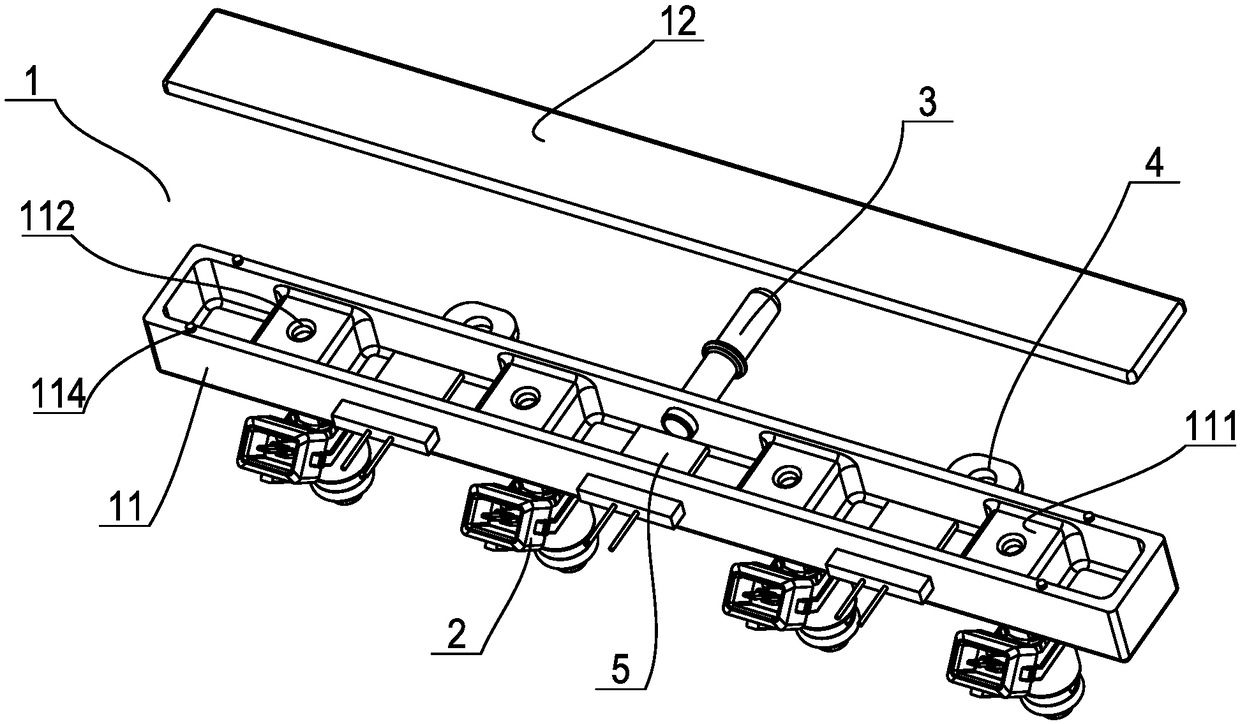

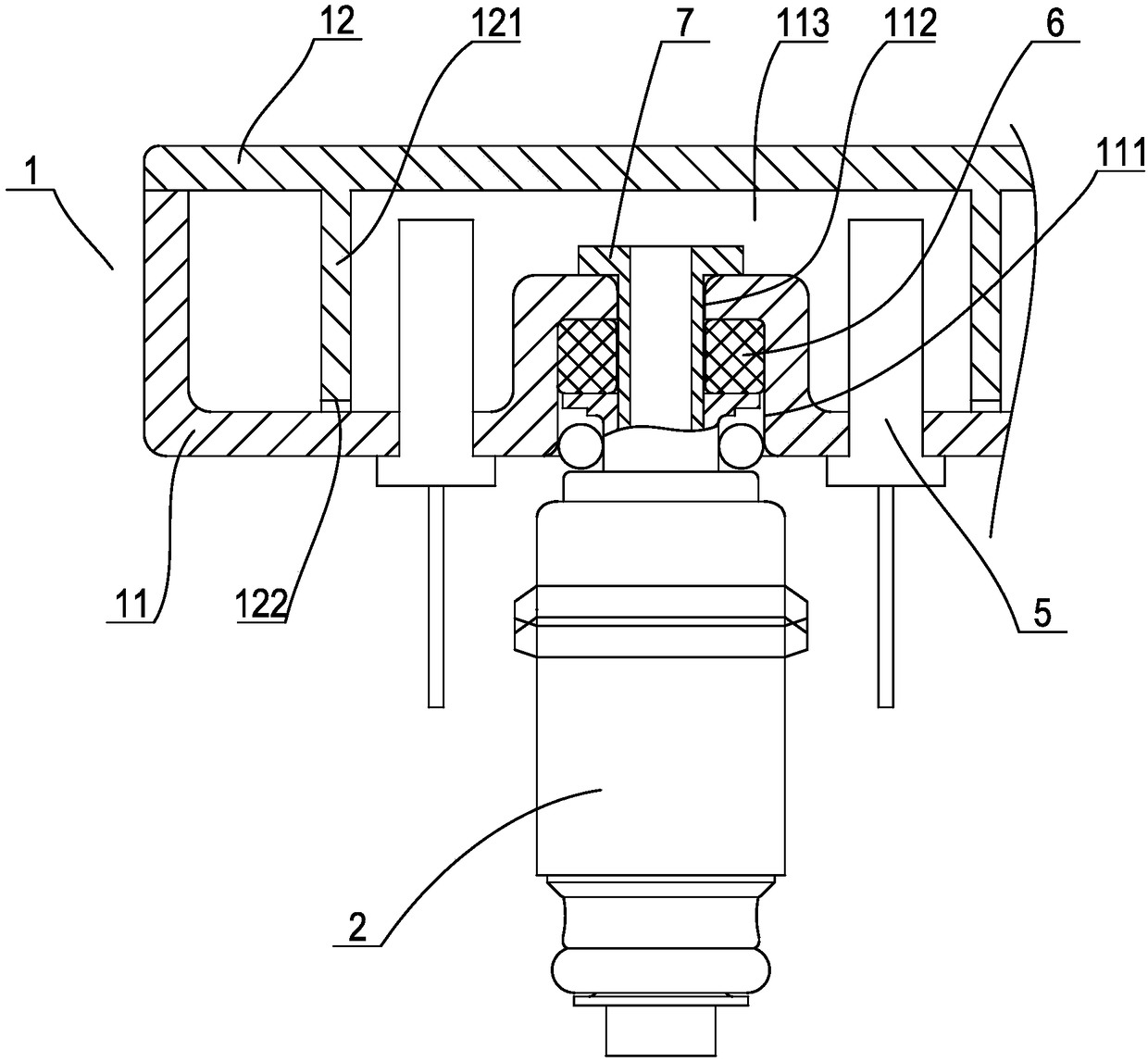

[0031] Such as figure 1 As shown, an engine high-pressure fuel rail assembly includes a tubular fuel rail 1 with a rectangular cross section and four fuel injectors 2 . In order to facilitate processing and installation, the oil rail 1 of the present invention adopts a split structure. Specifically, the oil rail 1 includes a long box body 11, and the box body 11 forms an opening on one side of the length direction, thereby having two opposite A box cover 12 is welded on the opening of the box body 11 on the side surfaces, the bottom surface connecting the two sides, and the end surfaces at both ends. In addition, an oil inlet pipe 3 is provided in the middle of one side of the box body 11 to facilitate the input of high-pressure fuel, and a mounting bracket 4 is provided on the bottom surface of the box body 11 to install and fix the oil rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com