A self-grouting back pressure valve

A self-grouting and mud backflow technology, applied in wellbore/well components, earthwork drilling, wellbore flushing, etc., can solve the problems of plugging water holes, broken valve stems, large engineering volume, etc., and reduce the engineering volume. , The effect of preventing the back spray of mud and reducing the cost of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

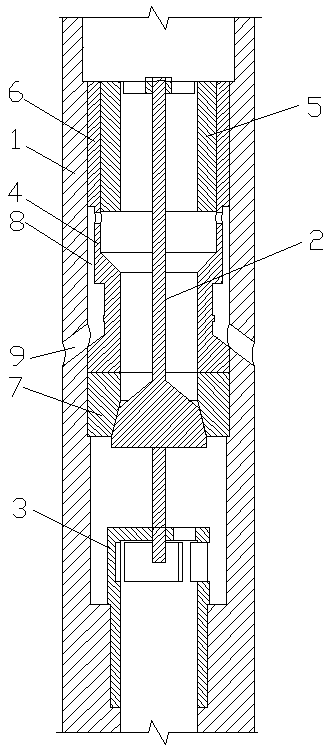

[0052] see figure 1 , a self-grouting back pressure valve, including a valve body 1, a valve core 2, a support seat 3 and a valve seat 4 arranged in the valve body 1, the support seat 3 is located below the valve seat 4, and the valve body 1 is set There is a piston 5, the piston 5 is set on the valve core 2, the valve seat 4 includes an upper valve seat 6 and a lower valve seat 7, the upper valve seat 6 is located between the piston 5 and the valve body 1, the upper valve seat 6 is provided with a mud return slot 8, and the mud return slot 8 communicates with the inner cavity of the valve body 1, and the valve body 1 is provided with a mud return hole 9, and the mud return slot 9 communicates with the mud return slot 8 .

[0053] This embodiment is the most basic implementation. A piston is arranged in the valve body, and the piston is sleeved on the valve core. The valve seat includes an upper valve seat and a lower valve seat. The upper valve seat is located between the pi...

Embodiment 2

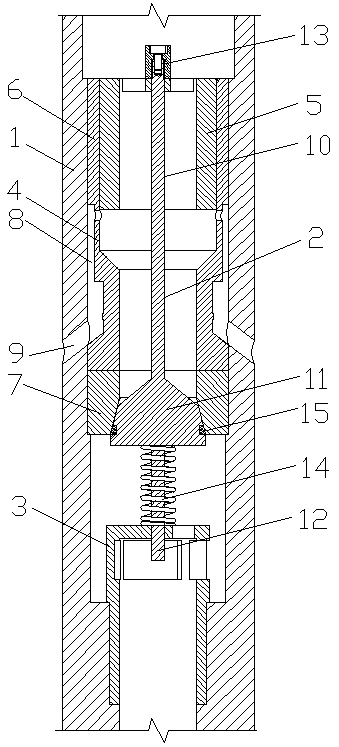

[0055] see figure 2 , a self-grouting back pressure valve, including a valve body 1, a valve core 2, a support seat 3 and a valve seat 4 arranged in the valve body 1, the support seat 3 is located below the valve seat 4, and the valve body 1 is set There is a piston 5, the piston 5 is set on the valve core 2, the valve seat 4 includes an upper valve seat 6 and a lower valve seat 7, the upper valve seat 6 is located between the piston 5 and the valve body 1, the upper valve seat 6 is provided with a mud return slot 8, and the mud return slot 8 communicates with the inner cavity of the valve body 1, and the valve body 1 is provided with a mud return hole 9, and the mud return slot 9 communicates with the mud return slot 8 .

[0056] Described spool 2 comprises upper valve stem 10, conical block 11 and lower valve stem 12 successively from top to bottom, and the upper end of upper valve stem 10 is provided with fixing nut 13, and the lower end is connected with the small end of...

Embodiment 3

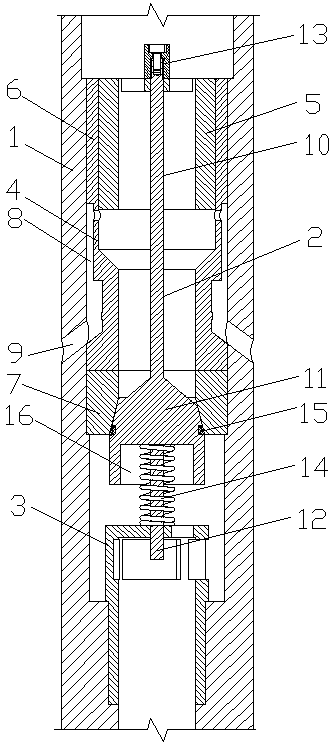

[0061] see image 3, a self-grouting back pressure valve, including a valve body 1, a valve core 2, a support seat 3 and a valve seat 4 arranged in the valve body 1, the support seat 3 is located below the valve seat 4, and the valve body 1 is set There is a piston 5, the piston 5 is set on the valve core 2, the valve seat 4 includes an upper valve seat 6 and a lower valve seat 7, the upper valve seat 6 is located between the piston 5 and the valve body 1, the upper valve seat 6 is provided with a mud return slot 8, and the mud return slot 8 communicates with the inner cavity of the valve body 1, and the valve body 1 is provided with a mud return hole 9, and the mud return slot 9 communicates with the mud return slot 8 .

[0062] Described spool 2 comprises upper valve stem 10, conical block 11 and lower valve stem 12 successively from top to bottom, and the upper end of upper valve stem 10 is provided with fixing nut 13, and the lower end is connected with the small end of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com