Wing-spreading shelter and its unfolding and withdrawing method

A shelter and wing-spreading technology, which is applied in the field of shelters and container equipment, can solve the problems that large-scale wing-spreading shelters cannot be realized, cannot meet special production conditions, have no heat preservation, rainproof and dustproof functions, and achieve deployment and withdrawal. The collection time is short, the effect of ensuring that the unfolding is not deformed, and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

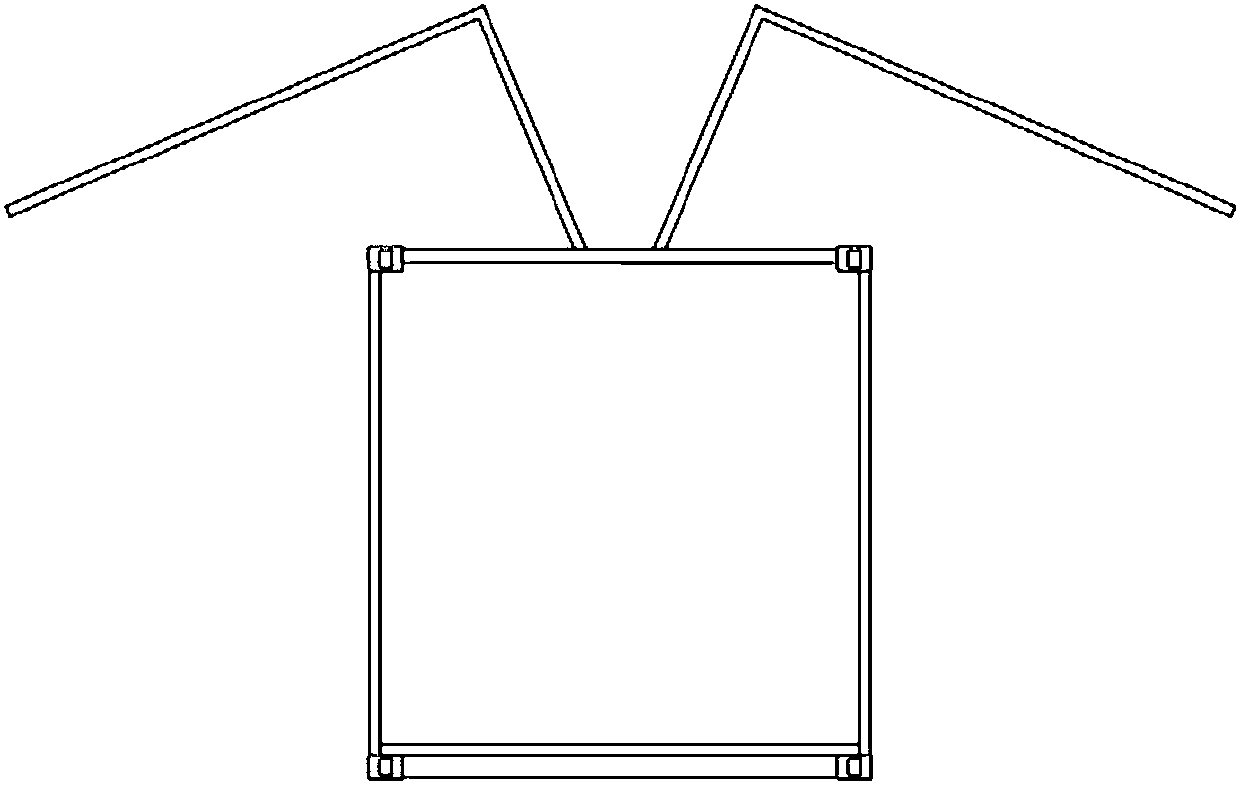

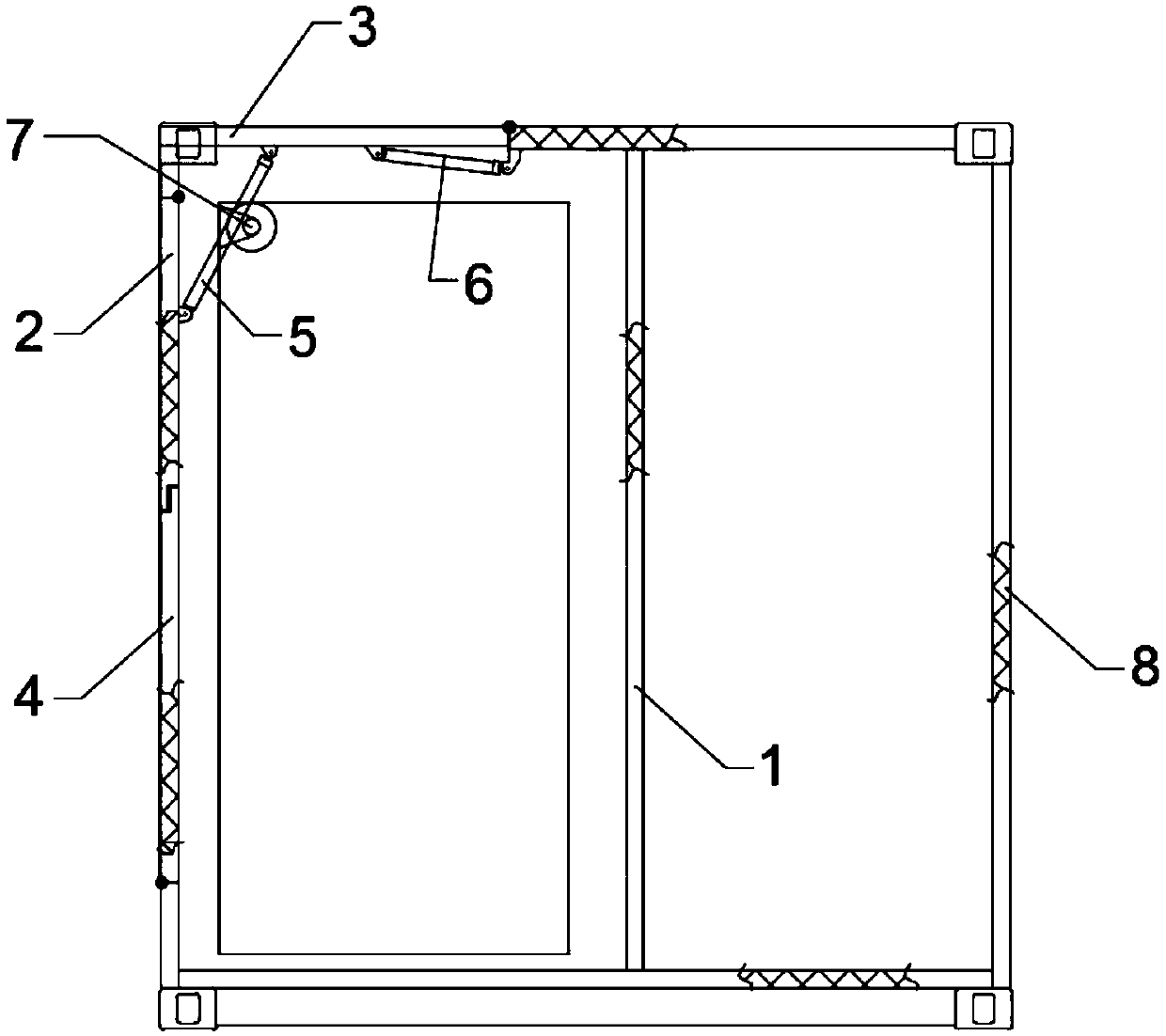

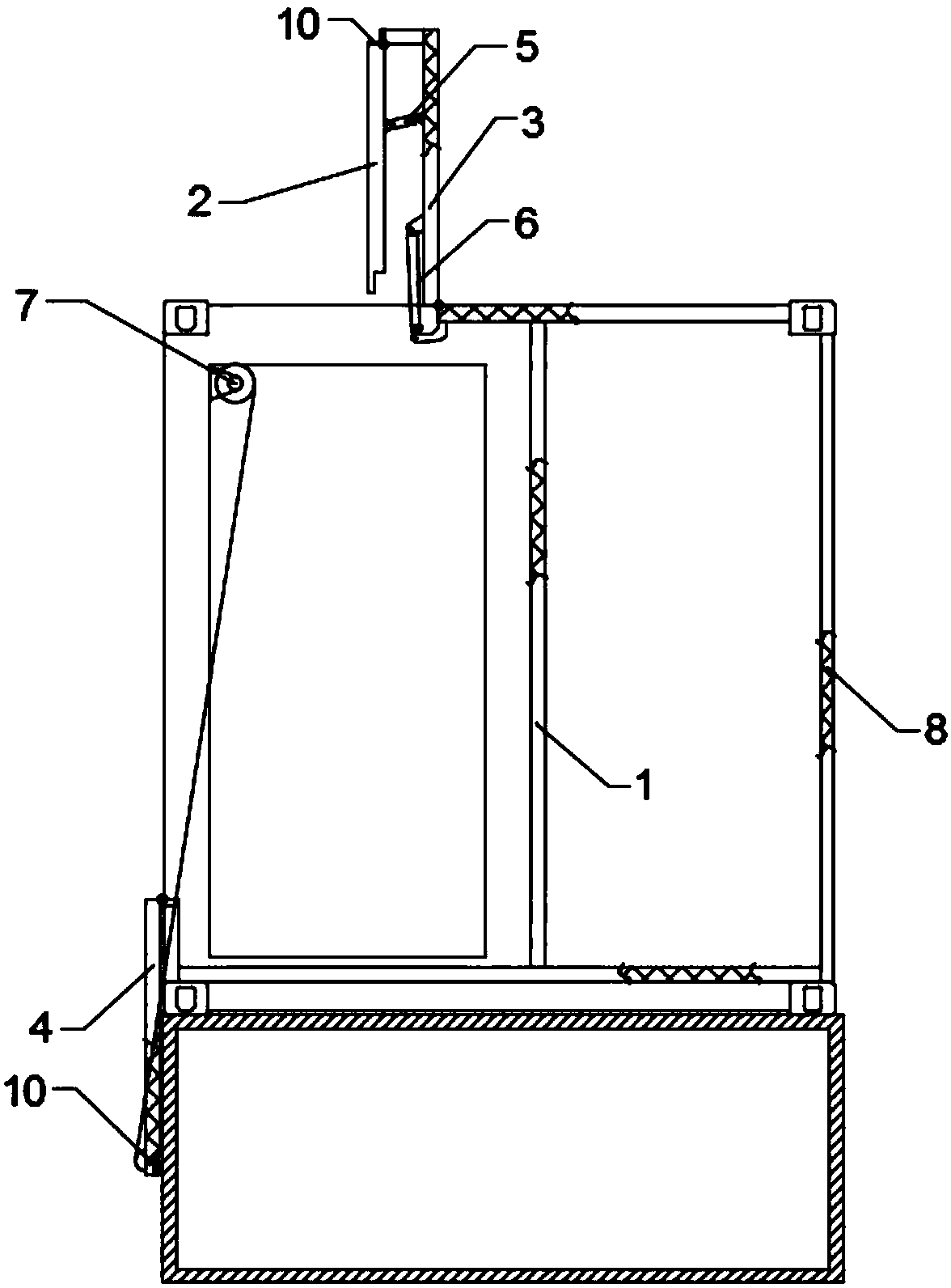

[0034] The wing-spreading shelter of this embodiment includes a shelter main body 1, a side upper wing 2, a top wing 3, a side lower wing 4, a hydraulic device 5, a hydraulic device 2 6, and a winch 7; the side upper wing 2 is hinged with the top wing 3, the top wing 3 is hinged with the top center of the shelter main body 1, the side lower wing 4 is hinged with the bottom of the shelter main body 1, the side lower wing 4 is provided with a hook, and the winch 7 is fixed in the shelter At the top corner of the main body 1, one end of the steel cable is wound on the winch 7, and the other end of the steel cable can be disconnected from the hook on the side lower wing plate 4; one end of the hydraulic device one 5 is fixed on the inner side of the top wing plate 3, and the other end It is fixed on the inner side of the side upper wing 2; one end of the hydraulic device 26 is fixed on the inner side of the top wing 3, and the other end is fixed on the top center of the inner side ...

Embodiment 2

[0036] The wing-spreading shelter of the present embodiment is the same as Embodiment 1 except the following differences:

[0037] The side upper wing 2, the top wing 3, and the side lower wing 4 are provided with sealing strips 10; the winch 7 is a manual winch, and the main body of the shelter is provided with a production operation area 12 and a plurality of separate compartments 11; The inner sides of the upper wing 2, the top wing 3 and the side lower wing 4 are all provided with an insulation layer 8, and the insulation layer 8 is made of thermal insulation rock wool board, which is close to the side upper wing 2, the top wing 3 and the side lower wing 4 each side of the inner wall.

[0038] The expansion steps of the wing-spreading shelter of the present embodiment are:

[0039] Step 101: Unlock the latch for locking the upper side wing 2 and the lower side wing 4;

[0040] Step 102: Start the hydraulic device, and the hydraulic device 2 6 is extended, driving the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com