Full-automatic electropolishing equipment

An electrolytic polishing, fully automatic technology, applied in the electrolytic process, electrolytic components and other directions, can solve the problems of low hourly output, high labor cost, difficult recruitment, etc., to achieve the effect of large clamping force, improve product quality, and prevent short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

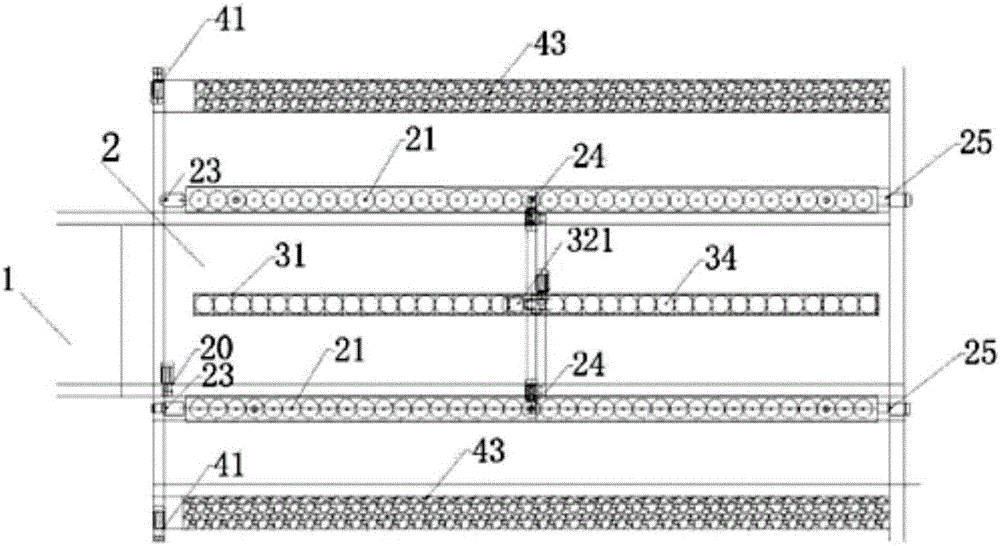

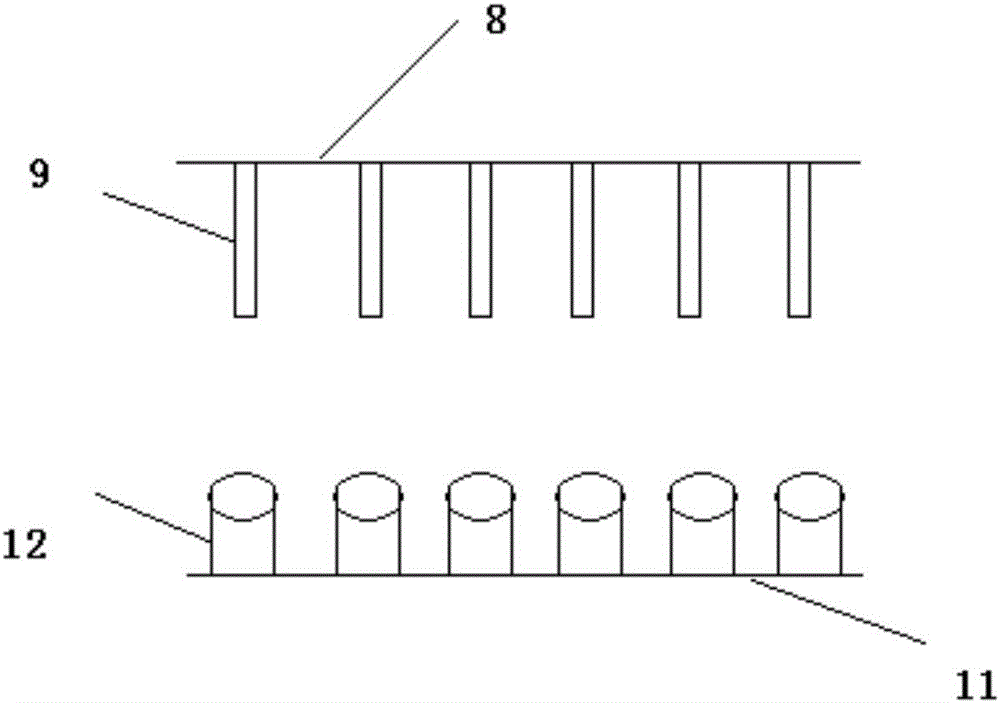

[0040] This embodiment provides a kind of automatic electrolytic polishing equipment, such as figure 1 and figure 2 As shown, it includes two sets of electrolysis tables 21, a primary conveyor belt 1, a secondary conveyor belt 2, a mechanical glove set 31, an overturning mechanism 25, two sets of cup inversion conveyor belts 43, a motor and a cleaning device. An anode plate platform 11 is provided on the electrolysis table 21, and a cathode rod 9 is arranged at a certain distance above the anode plate platform 11, and the polishing cup 12 is placed on the anode plate platform 11; After the control descends, it extends into the polishing cup 12 for a certain distance along the axis of the polishing cup 12 and does not contact the inner wall of the cup (to ensure that the cathode and anode will not be short-circuited during the electrolytic polishing process), and the electrolyte is passed through the polishing cup 12 at the same time. One end of the cathode rod 9 in the cup i...

Embodiment 2

[0061] Such as figure 2 As shown, in the present embodiment, an anode plate platform 11 is provided on the electrolysis platform, a cathode plate 8 is arranged at a certain distance above the anode plate platform 11, and a plurality of cathode rods 9 are arranged on the cathode plate 8, and the polishing cup 12 is placed On the anode plate platform 11; the cathode plate 8 is connected to the lifting mechanism, and the cathode plate 8 is controlled by the lifting mechanism to ensure that multiple cathode rods 9 rise and fall at the same time and perform electrolytic polishing on multiple polishing cups 12. During electropolishing, a plurality of cathode rods 9 descend and extend into the polishing cup 12 along the axis of the corresponding polishing cup 12 for a certain distance without contacting the inner wall of the cup (to ensure that the cathode and anode will not short circuit during the electropolishing process) , Electrolyte is injected into the cup body by stretching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com