Automatic flaw detection device suitable for detection of rail train wheelset

A train wheel and train wheel technology, which is applied in the direction of wheel rim measurement/measurement, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of potential safety hazards, low detection efficiency, easy misjudgment and missed judgment, etc. The effect of high detection probability, strong flaw detection ability and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] The automatic flaw detection equipment suitable for rail train wheel set detection provided by the present invention is equipped with a secondary lifting platform, and the rotary platform located on the upper part of the equipment is equipped with a slewing mechanism, which has a 180-degree rotation function, so that the flaw detection equipment can be inspected and maintained according to the rail train trench environment and The height of the detection platform can be flexibly adjusted in the space under the vehicle, and the detection position can be freely selected.

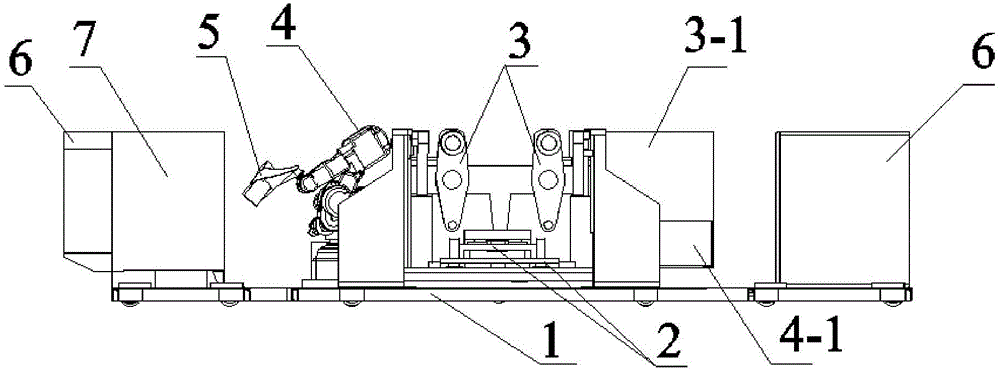

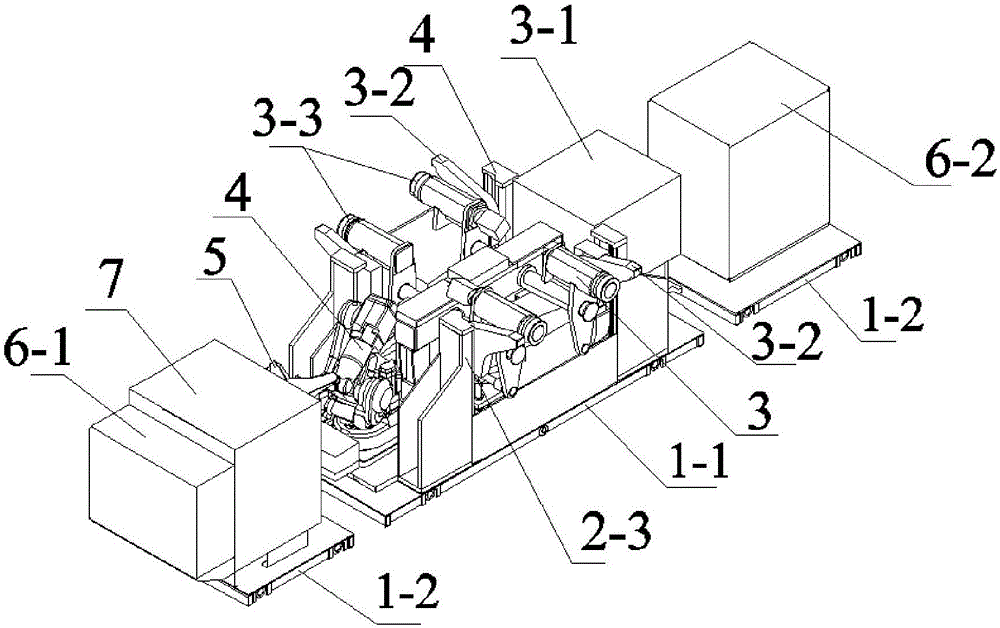

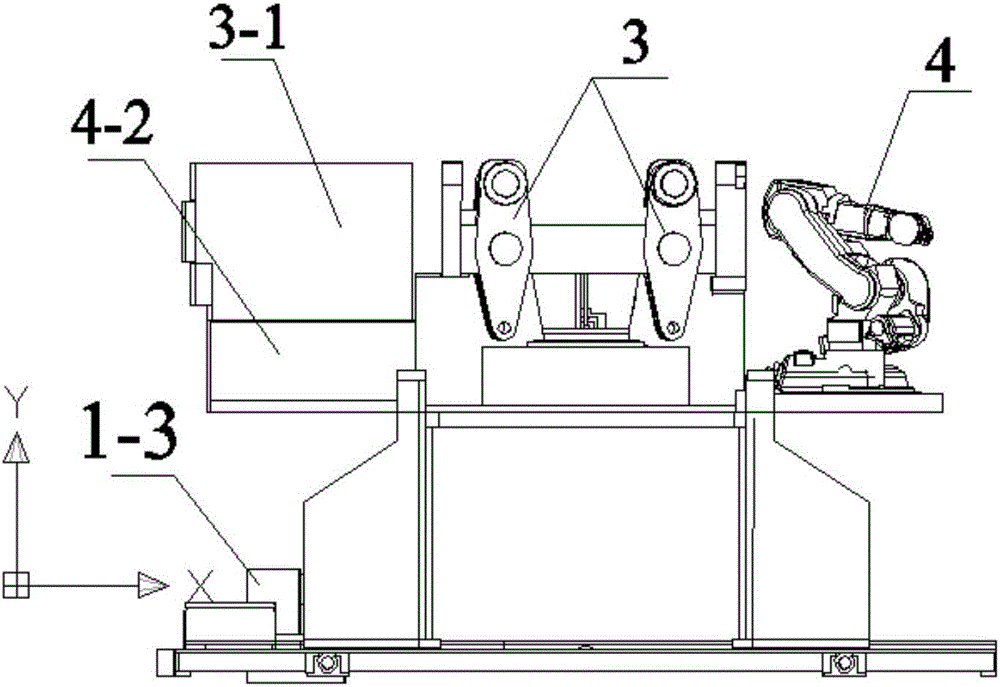

[0039] see figure 1 , 2 , 3, 4, what the present invention describes is an automatic flaw detection equipment suitable for rail train wheel set d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com