Rapid crushing and recycling device for town refuse

A technology of urban garbage and recycling device, applied in grain processing, fluid using vibration, removal of solid waste, etc., can solve the problem of slow garbage crushing, and achieve the effect of fast crushing, cost reduction and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

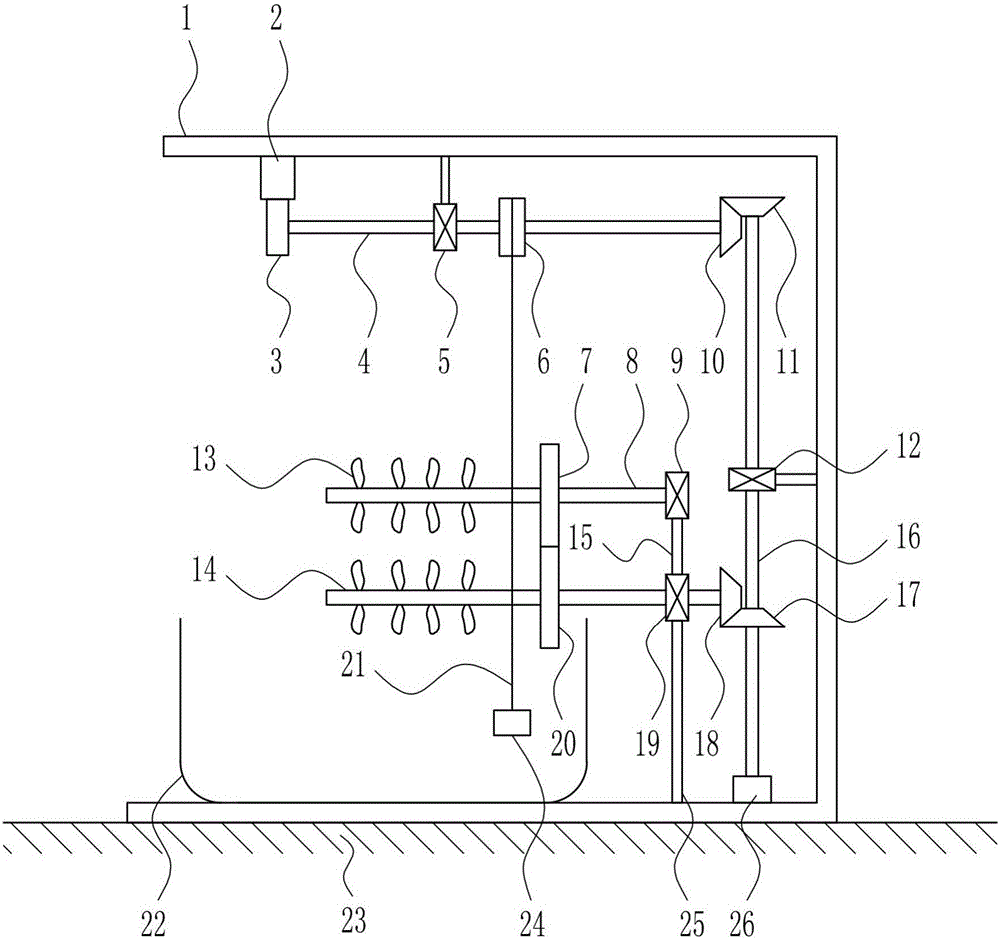

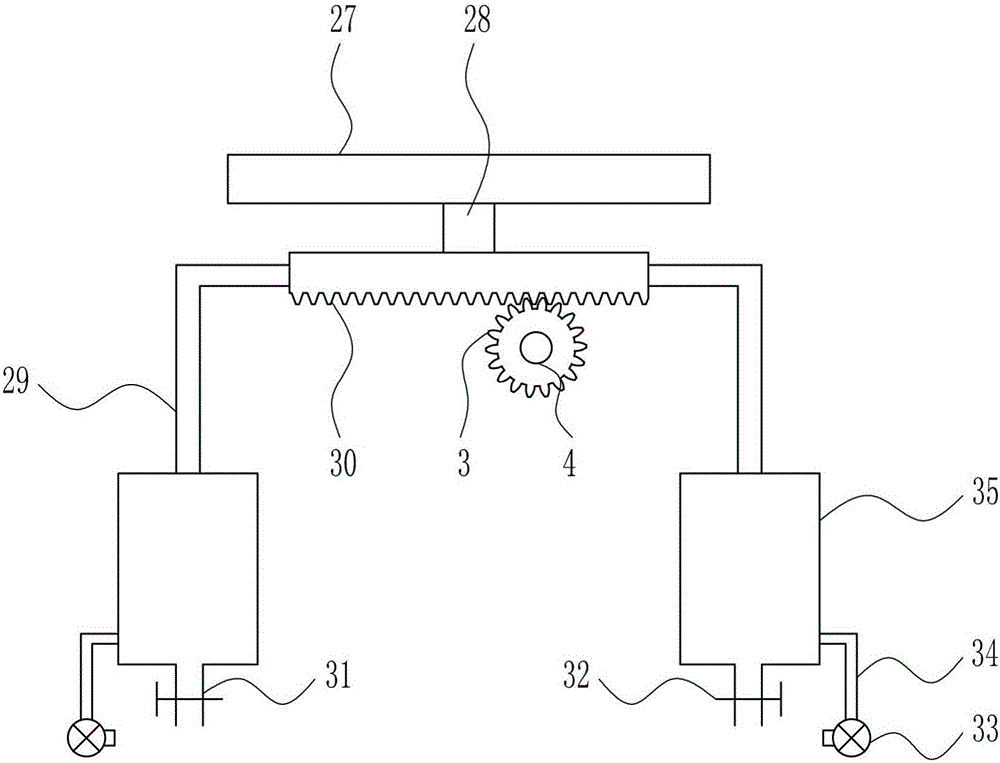

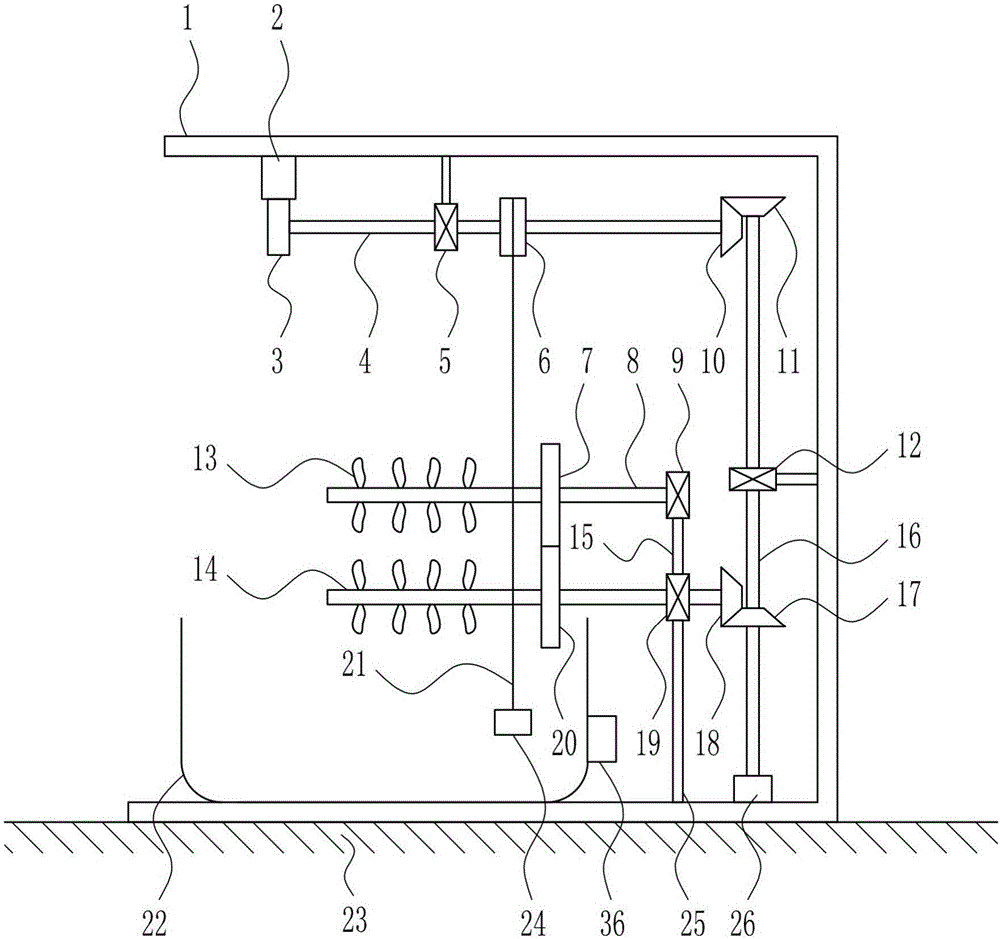

[0030] A kind of rapid crushing and recycling device for urban waste, such as Figure 1-6As shown, it includes a bracket 1, a disinfection device 2, a first gear 3, a first rotating shaft 4, a first bearing seat 5, a winding wheel 6, a second gear 7, a second rotating shaft 8, a second bearing seat 9, a first One bevel gear 10, the second bevel gear 11, the third bearing seat 12, the blade 13, the third rotating shaft 14, the first pole 15, the fourth rotating shaft 16, the third bevel gear 17, the fourth bevel gear 18, the fourth bevel gear Bearing seat 19, third gear 20, pull wire 21, collection tank 22, sachet 24, second pole 25 and motor 26; support 1 is placed on the ground 23, and the inner bottom of support 1 is provided with collection tank in turn from left to right 22. The second pole 25 and the motor 26, the upper end of the second pole 25 is connected with the fourth bearing seat 19, the third rotating shaft 14 is installed on the fourth bearing seat 19, the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com