Impeller type aerator

An aerator and impeller-type technology, applied in the field of impeller-type aerators, can solve the problems of increased use cost, inability to aerate deep water bodies, and limited use of impeller-type aerators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

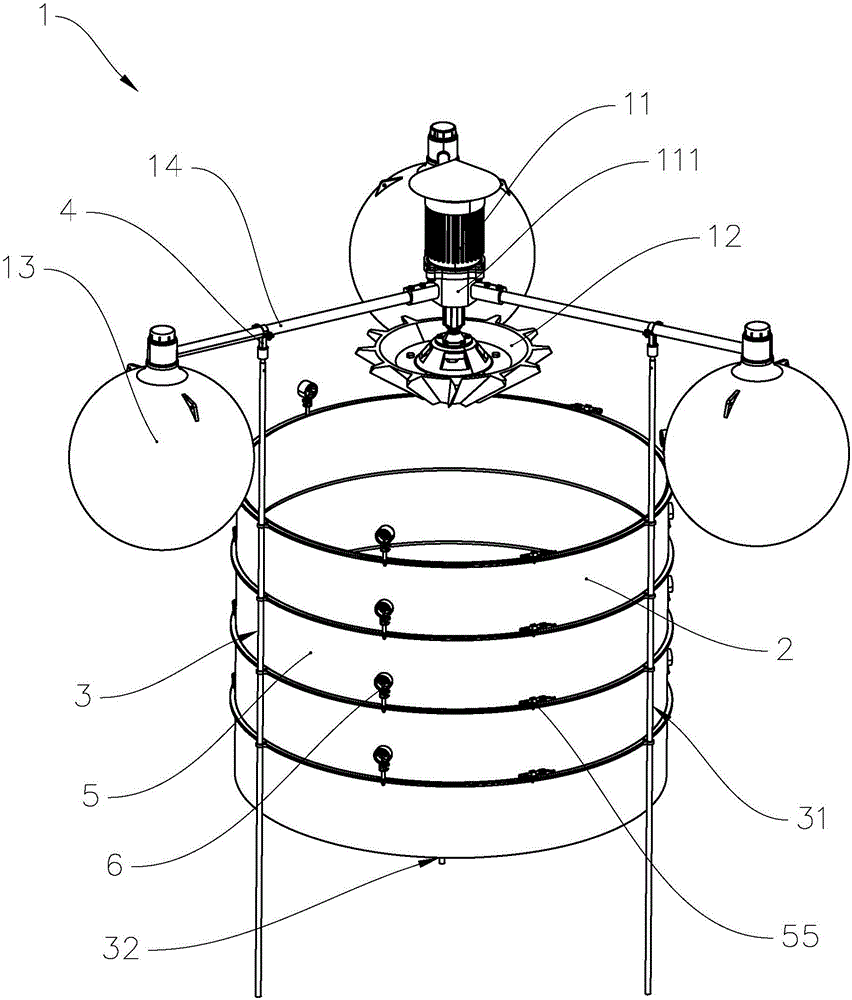

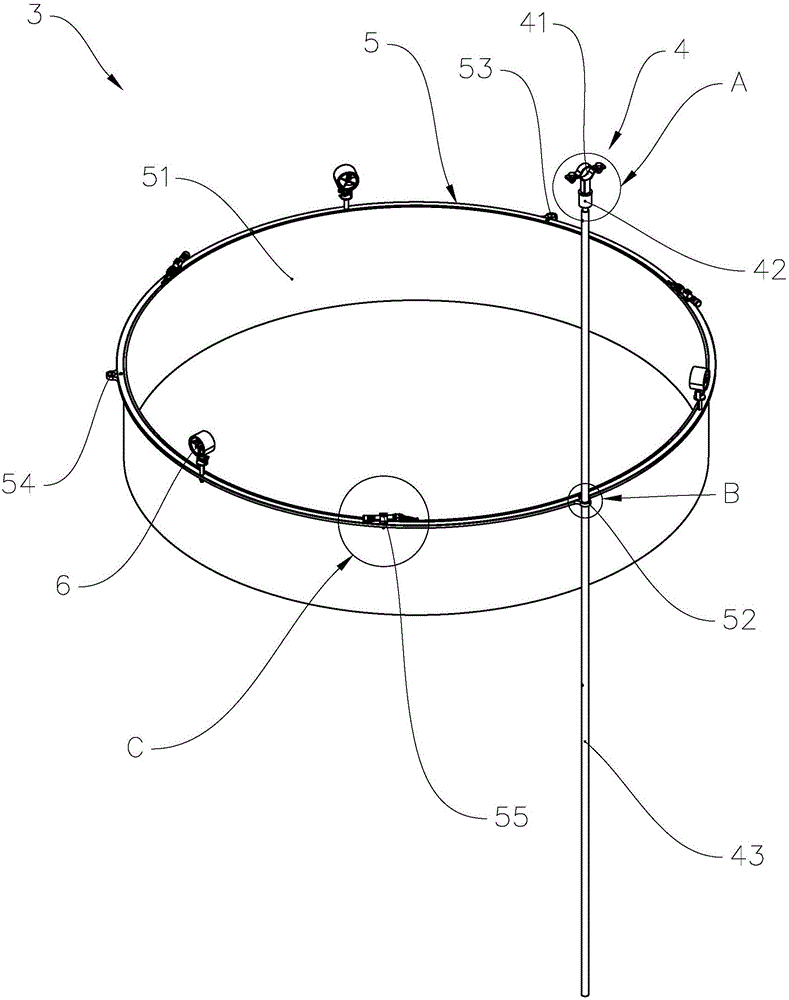

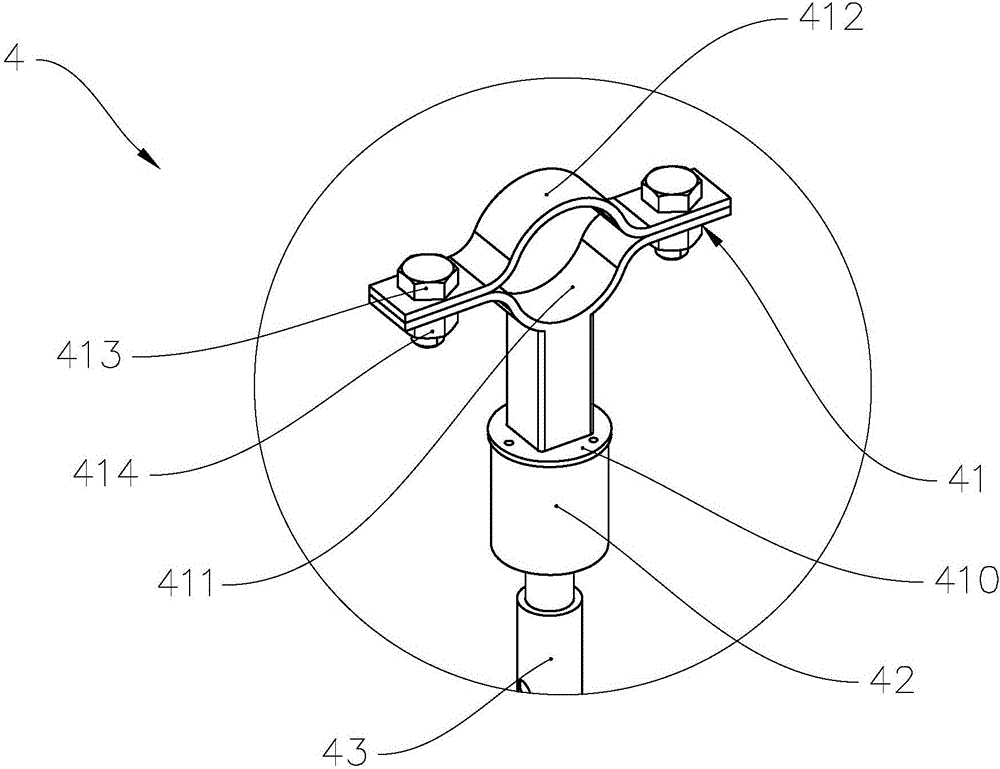

[0030] refer to figure 1 and figure 2 , figure 1 It is a structural diagram of an embodiment of the impeller type aerator of the present invention. figure 2 It is a structural diagram of the drainage unit of the embodiment of the impeller type aerator of the present invention. The impeller type aerator 1 includes a motor 11, an impeller 12, a floating body 13, a connecting rod 14, a drainage ring 2, a drainage unit 3, a drainage unit 31, a drainage unit 32 and a control module.

[0031] The motor 11 is provided with a connecting seat 111, the first end of the connecting rod 14 is fixedly connected to the connecting seat 111, the second end of the connecting rod 14 is fixedly connected to the floating body 13, the output shaft of the motor 11 is fixedly connected to the impeller, and the control module passes to the motor The first control signal output by 11 controls the start and stop of the motor 11 . Specifically, the number of floating bodies 13 is three, the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com