Equipment for automatically picking up cherries

A technology for automatic picking and cherry picking, which is applied in the fields of picking machines, agricultural machinery and implements, and applications, and can solve the problems of small cherries, cumbersome and scattered picking work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

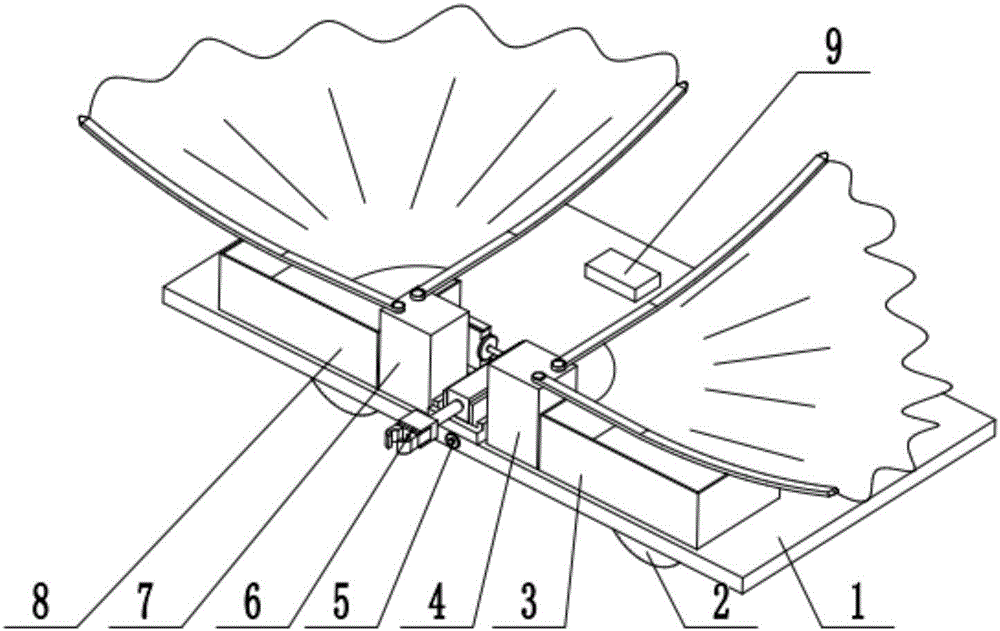

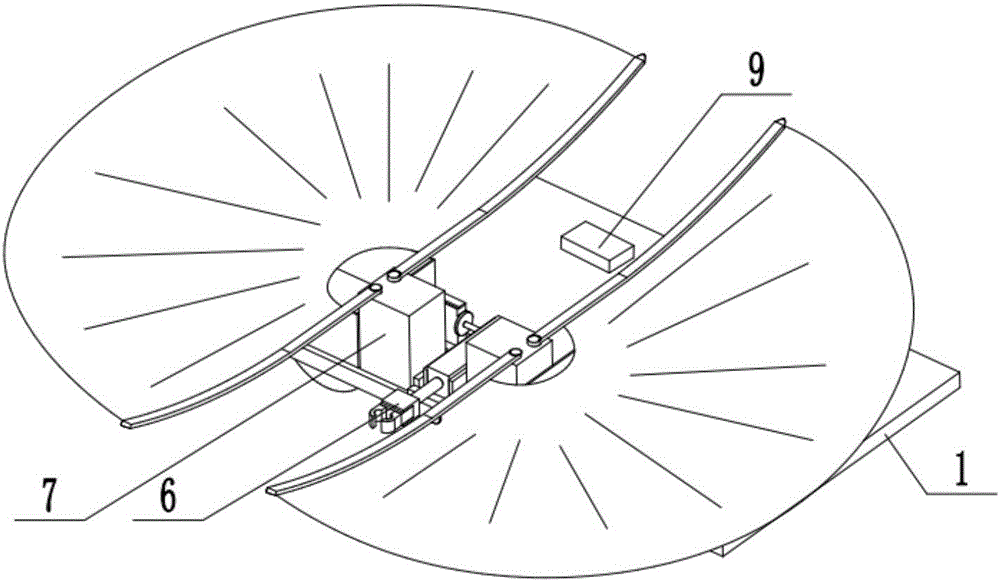

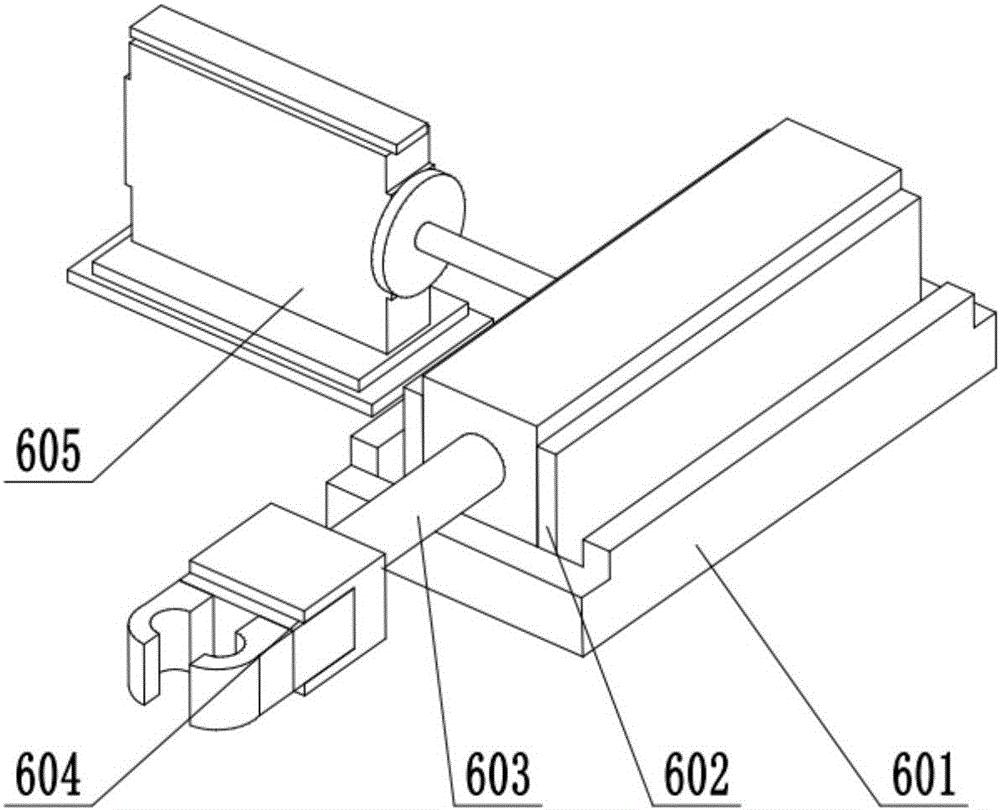

[0014] A device for automatically picking cherries is composed of chassis 1, wheels 2, first cargo box 3, first motor box assembly 4, CCD5, oscillation assembly 6, second motor box assembly 7, second cargo box 8, controller 9. Stepping motor 10, gear 11, sliding sleeve 601, cylinder guard 602, cylinder 603, pneumatic gripper 604, vibration exciter 605, motor housing 701, umbrella rod 702 and umbrella cloth 703 are composed of Four wheels 2 are installed under the chassis 1. The first cargo box 3 and the second cargo box 8 are installed on the upper surface of the chassis 1. The first motor box assembly 4 is installed on the upper surface of the chassis 1 close to the first cargo box 3, and the second The motor box assembly 7 is installed on the upper surface of the chassis 1 close to the second cargo box 8. The vibration assembly 6 is installed on the upper surface of the chassis 1 in the middle of the first motor box assembly 4 and the second motor box assembly 7, and the CCD 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com