Optical cable pigtail separated type telescopic optical fiber coiling device

A separate, telescopic disc technology, which is applied in the field of optical cable laying, can solve the problems of no tail fiber loop, irregularity, mechanical damage, etc., and achieve the effect of preventing looseness, tidy wiring, and preventing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

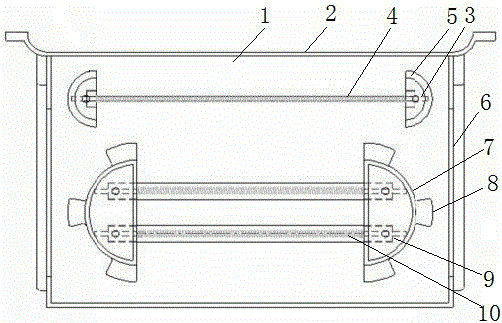

[0015] Such as figure 1 The shown a kind of optical fiber pigtail separation telescopic coiling device includes a separate storage tray composed of a rectangular bottom plate 1 and a frame 2 connected to the four sides of the bottom plate 1. The outline of the separate storage tray is consistent with the ODF unit box The plug-in modules are the same; the frame 2 on the side of the separate storage tray is provided with an optical cable pigtail inlet and outlet 6; the bottom plate 1 is provided with a telescopic fiber mechanism and a large-capacity telescopic storage mechanism, and the The mechanism consists of a guide rod 3 fixedly connected to the bottom plate 1, two openings that are relatively slidably connected to the fiber arcs 5 at both ends of the guide rod 3, and a telescopic telescopic arm that is sleeved on the guide rod 3 and connected to two fiber arcs 5 at both ends. Composed of spring 4, the outer wall of the winding fiber arc 5 is provided with wire grooves; the...

Embodiment 2

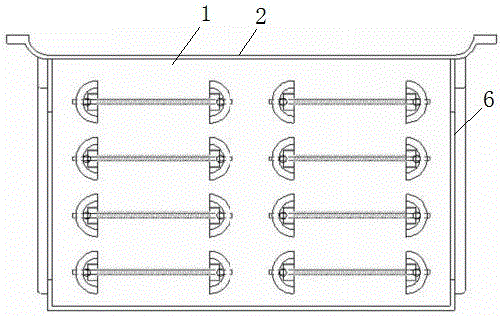

[0018] Such as figure 2 The shown a kind of optical fiber pigtail separation telescopic coiling device includes a separate storage tray composed of a rectangular bottom plate 1 and a frame 2 connected to the four sides of the bottom plate 1. The outline of the separate storage tray is consistent with the ODF unit box The plug-in modules are the same; the frame 2 on the side of the separate storage tray is provided with an optical cable pigtail inlet and outlet 6, and the bottom plate 1 is provided with a plurality of telescopic fiber mechanisms, and the telescopic fiber mechanisms are fixedly connected On the guide rod 3 of the bottom plate 1, two openings are slidably connected to the fiber arcs 5 at both ends of the guide rod 3, and a telescopic spring 4 sleeved on the guide rod 3 and connected to two fiber arcs 5 at both ends. The outer wall of the fiber arc 5 is provided with wire slots.

[0019] A plurality of optical fiber pigtails are coiled on the telescopic fiber co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com