Visualization device and test method for simulating dynamic closure of discontinuous sand-laying joints

A non-continuous, sand-laying technology, which is applied in the direction of soil material testing and material inspection, can solve the problems that the change of porosity rate cannot be considered, the filtration loss of fracturing fluid cannot be simulated, and the condition of proppant sand column cannot be directly observed. Achieve the effect of simple structure, effective test method and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

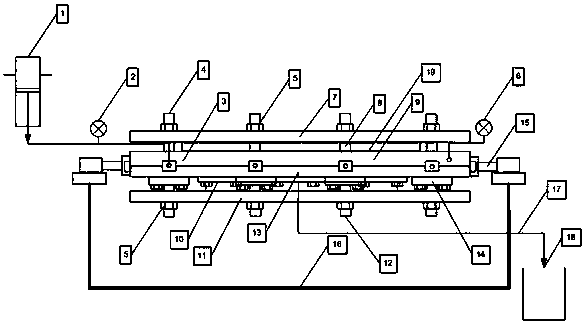

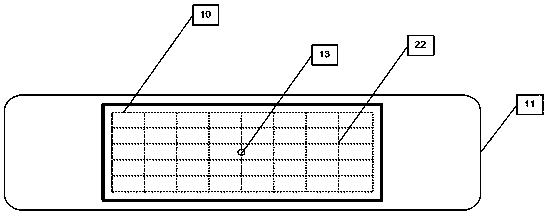

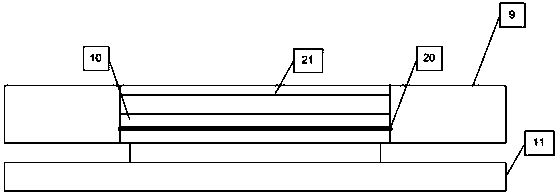

[0035] A visualization device for simulating the dynamic closure of discontinuous sand-spreading seams, including a driving mechanism, a visual mechanism, a casing 9, a movable piston plate 10 and an artificial rock slab 21, the casing 9 is a hollow structure, the upper end is closed and the lower end is open , the artificial rock plate 21 is arranged on the movable piston plate 10, and the movable piston plate 10 is arranged in the housing 9, and the upper surface of the movable piston plate 10 is provided with a filter loss groove 22 and a filter loss hole 13, and the movable piston plate 10 is in sliding and sealing cooperation with the inner cavity of the housing 9 , the driving mechanism is connected with the movable piston plate 10 to drive the movable piston plate 10 to move in the inner cavity of the housing 9 , and the visible mechanism is arranged on the upper surface of the housing 9 .

[0036] The drive mechanism includes a hydraulic pump 1, a tee 3, a piston rod 12...

Embodiment 2

[0054] A method for testing a visualization device for simulating the dynamic closure of discontinuous sand-laying joints, comprising the following steps:

[0055] 1. Place the artificial rock plate 21 on the movable piston plate 10, prepare 2.432L of fiber fracturing fluid, and lay it on the artificial rock plate 21;

[0056] 2. Weigh 120g of proppant and prepare sand concentration of 360kg / m 3 The fiber carrying sand fluid, and the proppant sand column is non-uniformly laid on the upper surface of the artificial rock slab 21;

[0057] 3. Set the first sealing gasket 19 in the sealing groove on the upper surface of the housing 9, and place the visible glass 8 and the upper pressure plate 7 of the window in sequence;

[0058] 4. Fasten the window upper platen 7 and the visible glass 8 through the nut 5 and the screw rod 4; adjust the rotating locking shaft 15 so that the casing 9 and its connected window upper platen 7 and lower platen 11 are in the vertical direction;

[00...

Embodiment 3

[0068] This embodiment describes the device in the present invention with reference to the accompanying drawings.

[0069] Such as figure 1 As shown in -3, a visualization device for simulating the dynamic closure of discontinuous sand-laying seams is mainly composed of a hydraulic pump 1, an upper pressing plate 7 of a window, a lower pressing plate 11, a movable piston plate 10, a housing 9, an artificial rock plate 21, a hydraulic pressure Cylinder 14, piston rod 12, sight glass 8, support base 16, rotation locking shaft 15, first pressure gauge 2, second pressure gauge 6, waste liquid tank 18 are formed. The upper pressing plate 7 of the window and the visible glass 8 are fastened and bonded by the screw rod 4 and the nut 5; the visible glass 8 and the upper surface of the housing 9 are bonded and sealed by the first sealing gasket 19; the movable piston The plate 10 and the inner cavity of the housing 9 are bonded and sealed by the second sealing gasket 20; the housing 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com