An inner bag filling device for block-shaped pressed tea

A charging device and a technology for pressing tea, which are applied in directions such as packaging, can solve the problem of inability to apply a block-shaped pressing tea inner bag device, etc., and achieve the effects of high bagging efficiency, high quality and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described below with reference to the drawings. In order to fully understand the present invention, many details are described below, but for those skilled in the art, the present invention can be implemented without these details.

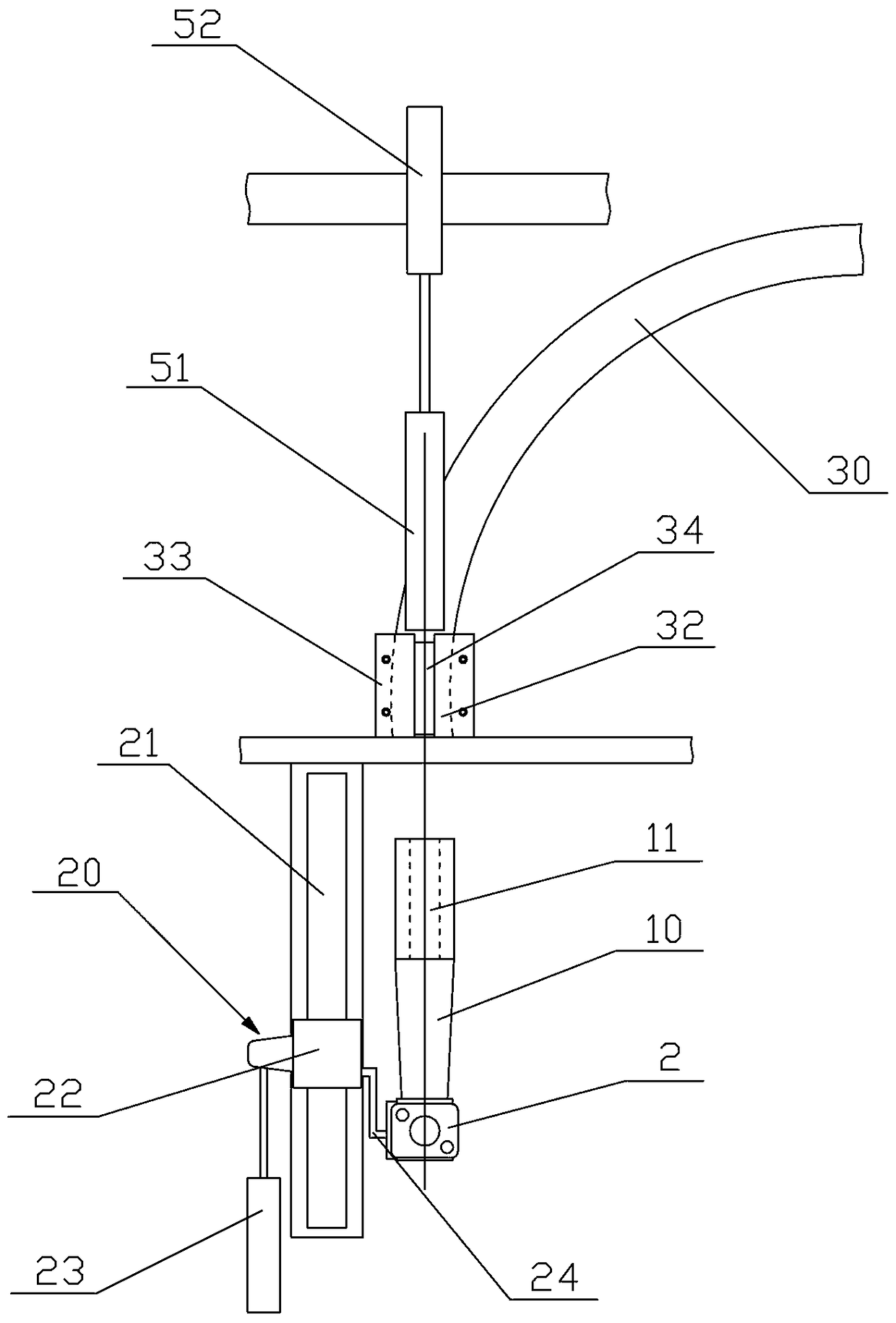

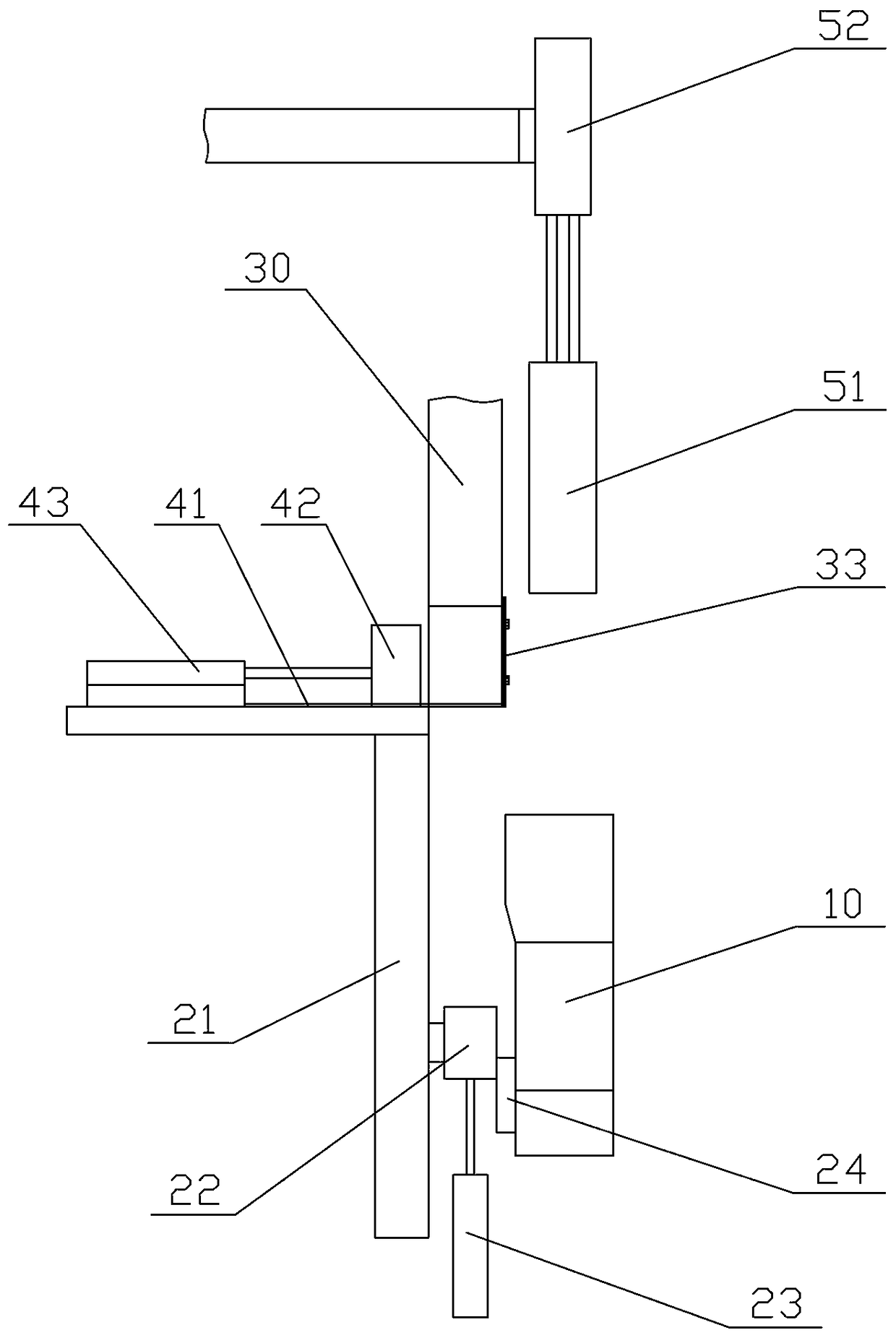

[0018] An inner bag filling device for compacted block tea, refer to figure 1 , Including a feeding hopper 10 that can be raised and lowered up and down, a driving mechanism 20 that drives the feeding hopper 10 up and down, and an inner bag film clamping mechanism 2 installed at the lower end of the feeding hopper 10 and matched with the side wall of the feeding hopper 10, and inner bag film clamping The mechanism is a common mechanism in the field, and the present invention will not be described in detail. The inner bag filling device also includes an arc track 30, a horizontal pushing mechanism and a vertical pushing mechanism. The arc track 30 is preferably a 90° arc track. The top e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com