Fiber paste spraying and conveying device

A technology for conveying device and fiber paste, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc., which can solve the problems of large floor area, fiber paste coating, electrical insulation short circuit, etc., and reduce the replacement of fiber The number of paste hoppers, avoiding the accumulation of fiber paste, and preventing the effect of valve blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

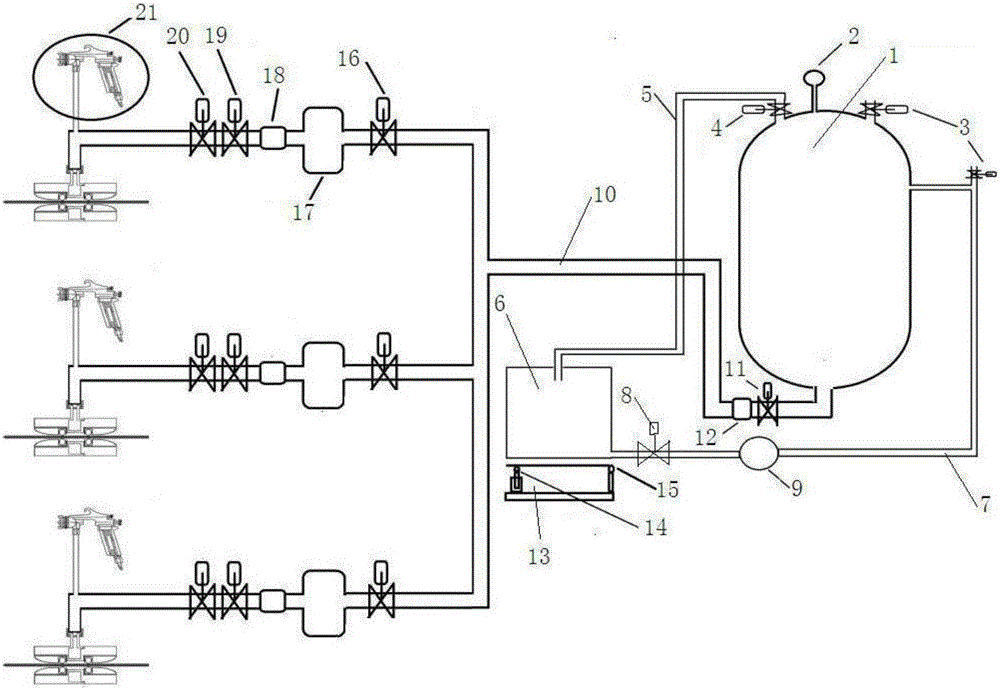

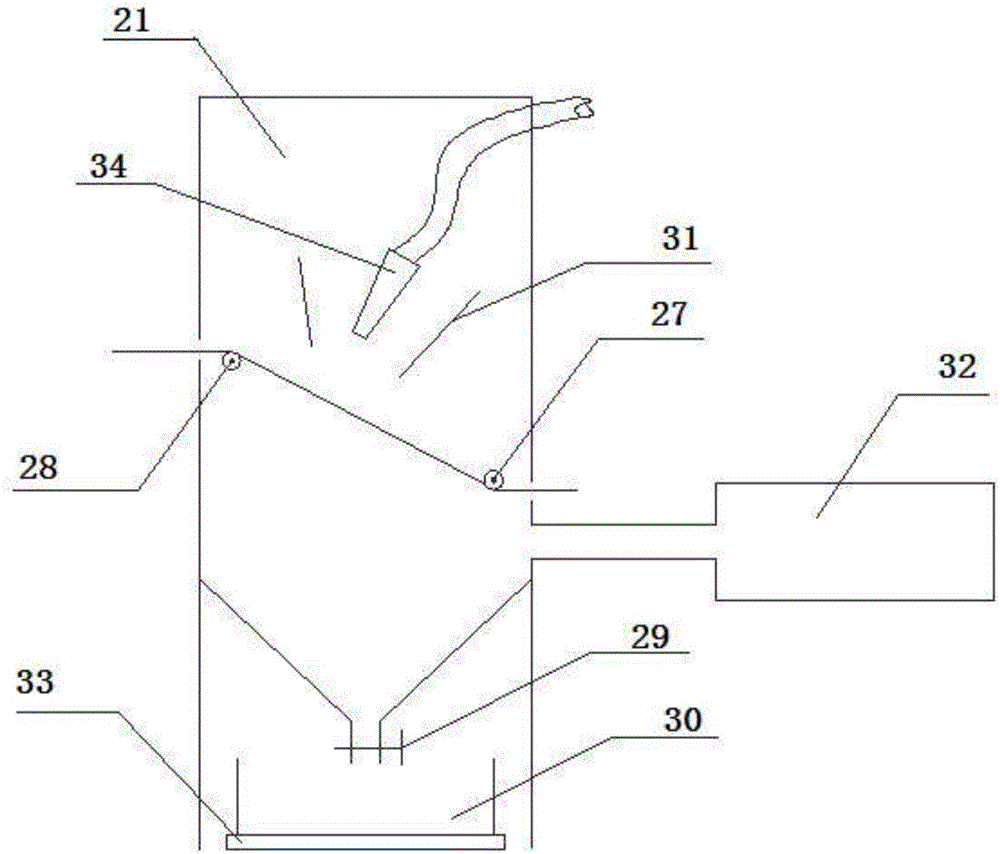

[0025] As shown in the figure, a fiber paste spraying and conveying device of the present invention includes a fiber paste conveying part and a fiber paste spraying part; it is characterized in that:

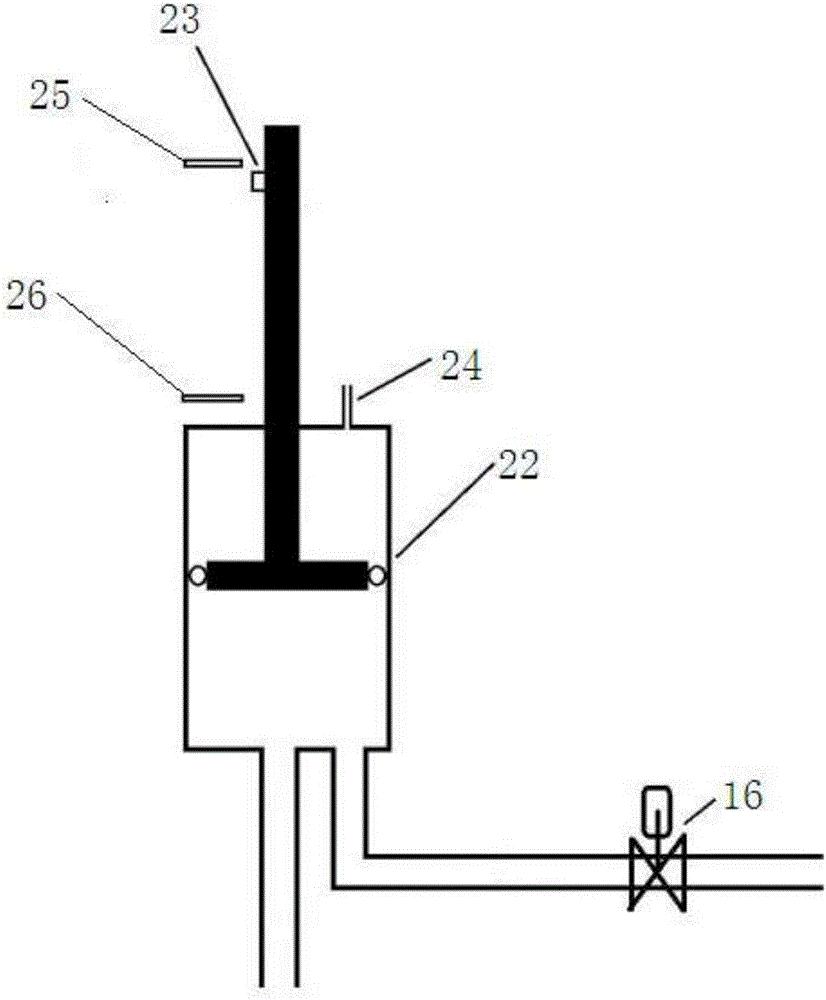

[0026] The fiber paste conveying part is as follows: a pressure gauge and a first controller 2 are connected to the upper part of the fiber paste pressure tank 1, and an exhaust valve 3 is connected to the tank body on one side of the pressure gauge to discharge the gas in the tank; An overpressure relief valve 4 is installed on the upper part of the tank body on the other side, and is connected with a first pipeline 5. The other end of the first pipeline is connected to the top of the fiber paste barrel. When the fiber paste pressure in the tank is greater than the set pressure, the overflow The flow valve is opened, and the fiber paste is guided into the fiber paste bucket by the pipeline; the second pipeline 7 is also connected to the tank body of the fiber paste pressure tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com