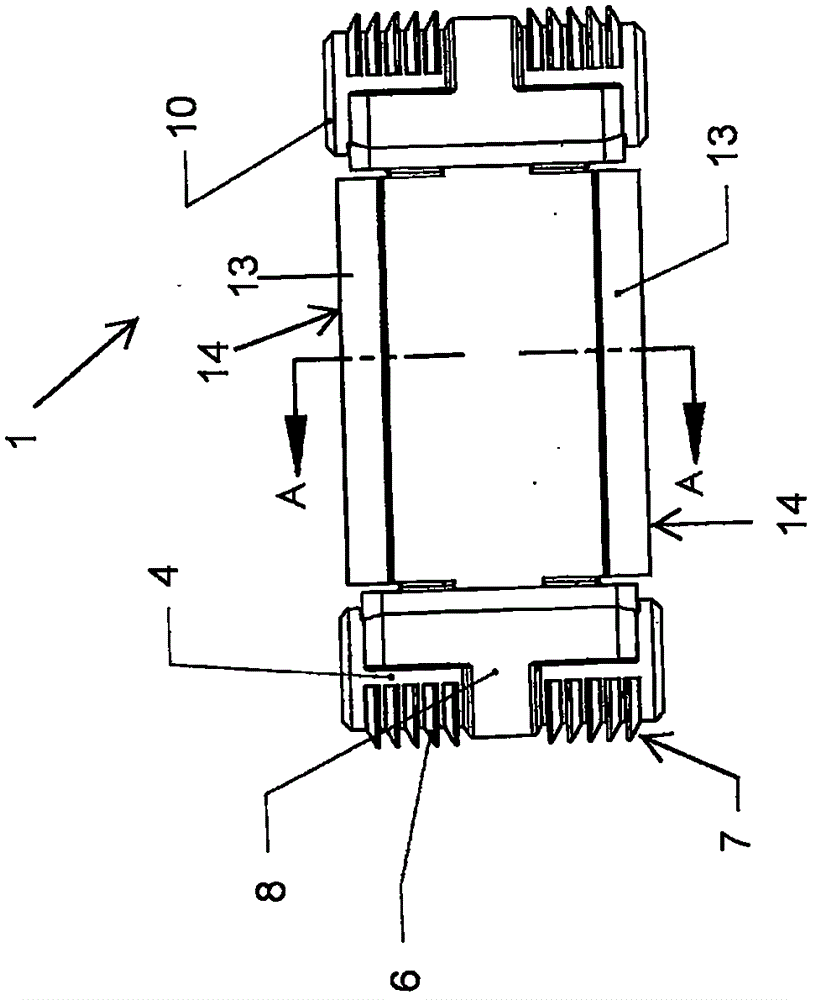

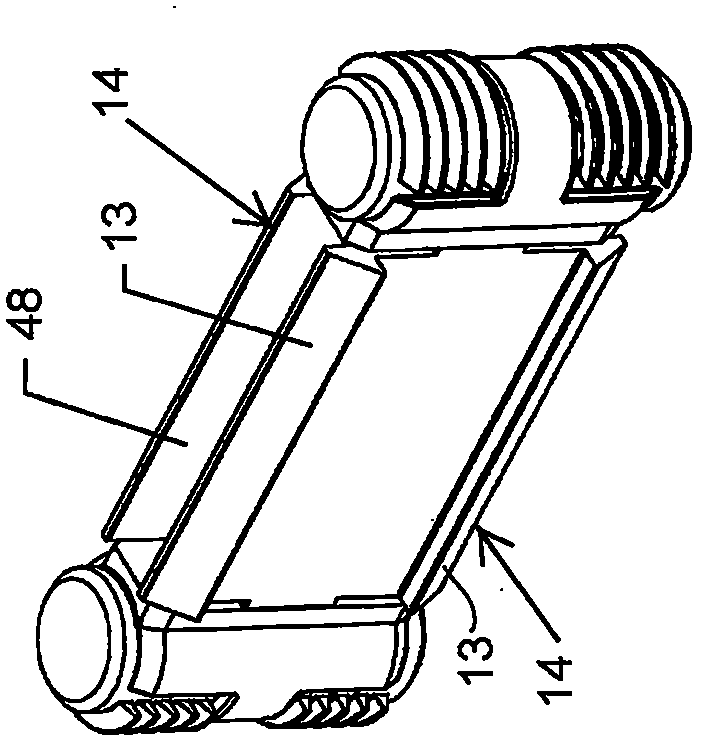

Clip lock fasteners and fastening system

A fastener and fastening technology, applied in the direction of connecting components, cabinets, detachable cabinets, etc., can solve problems such as cam lock failure, furniture falling off, and complicated processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

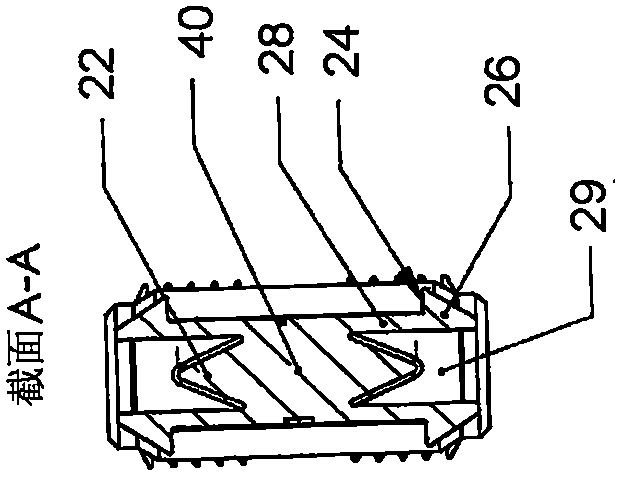

[0063] The description above and below and the drawings in this document focus on one or more currently preferred embodiments of the invention, and also describe some exemplary optional features and / or alternative embodiments. The description and drawings are for purposes of illustration and not limitation. Those of ordinary skill in the art will recognize variations, modifications and substitutions. Such variations, modifications and substitutions are also within the scope of the present invention. Some headings are general and are for convenience only.

[0064] The embodiment of the invention may be a piece of solid material. The embodiments of the present invention are ideally made of plastic or metal composite materials. Aluminum or steel can be used to build sheet metal type designs. The metal embodiment is used when shear strength is required for a specific structure, or in a higher temperature environment, so the fastener will not be plasticized. The objects to which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com