Sowing machine

A seeding machine and seeding shaft technology, applied in the field of seeding machines, can solve the problems of seeds being blocked, affecting the seeding efficiency, and the seeding cannot be carried out smoothly, so as to achieve good seeding effect and high seeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

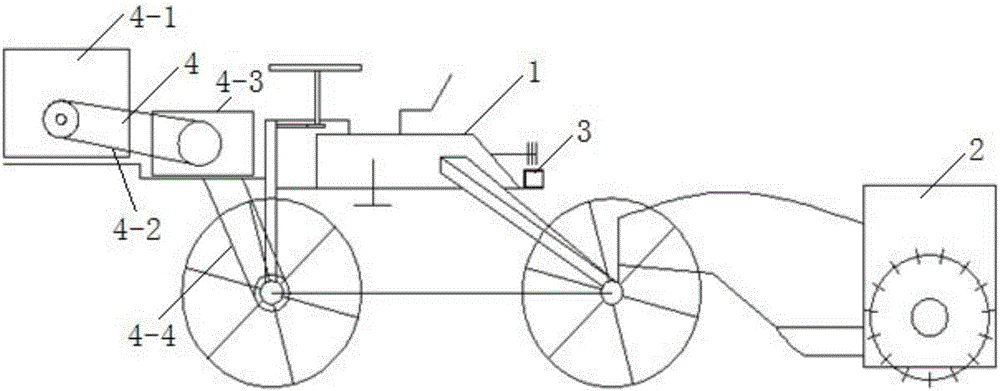

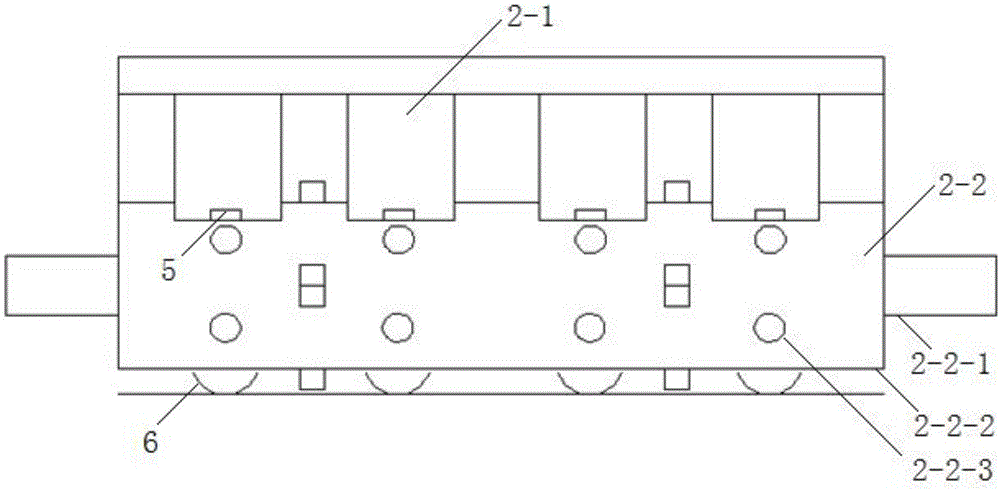

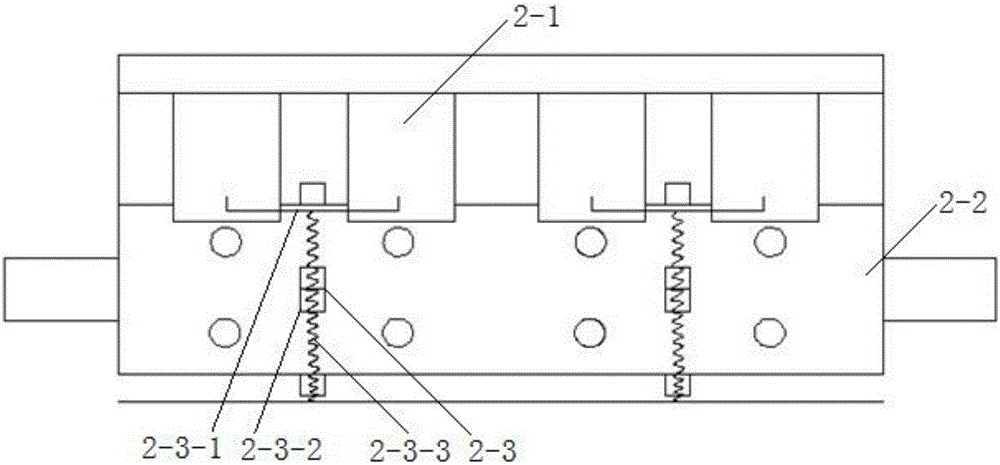

[0020] With reference to accompanying drawing, present embodiment comprises seeder body 1, and described seeder body 1 is provided with sowing device 2 and guiding device 3; Described sowing device 2 comprises sowing box 2-1, sowing shaft 2-2 and seed loose Device 2-3, the sowing box 2-1 is located on the sowing shaft 2-2, the sowing shaft 2-2 includes a rotating shaft 2-2-1, and a sleeve is arranged on the rotating shaft 2-2-1 2-2-2, the sleeve 2-2-2 is provided with a series of grooves 2-2-3 for holding seeds, wherein, in the axial direction of the sleeve 2-2-2, the grooves The grooves 2-2-3 are equidistantly arranged (the distance between two adjacent grooves is determined by the lateral spacing of the seeds), and on the circumference of the sleeve 2-2-2, the grooves 2-2-3 are evenly arranged ; The seed loosening device 2-3 includes a loosening bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com