Electric water valve for automobile air conditioner

An automotive air-conditioning and electric technology, applied in valve details, valve devices, engine components, etc., can solve problems such as inability to precisely control the rotation angle, installation space requirements, and easy failure of electromagnetic coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

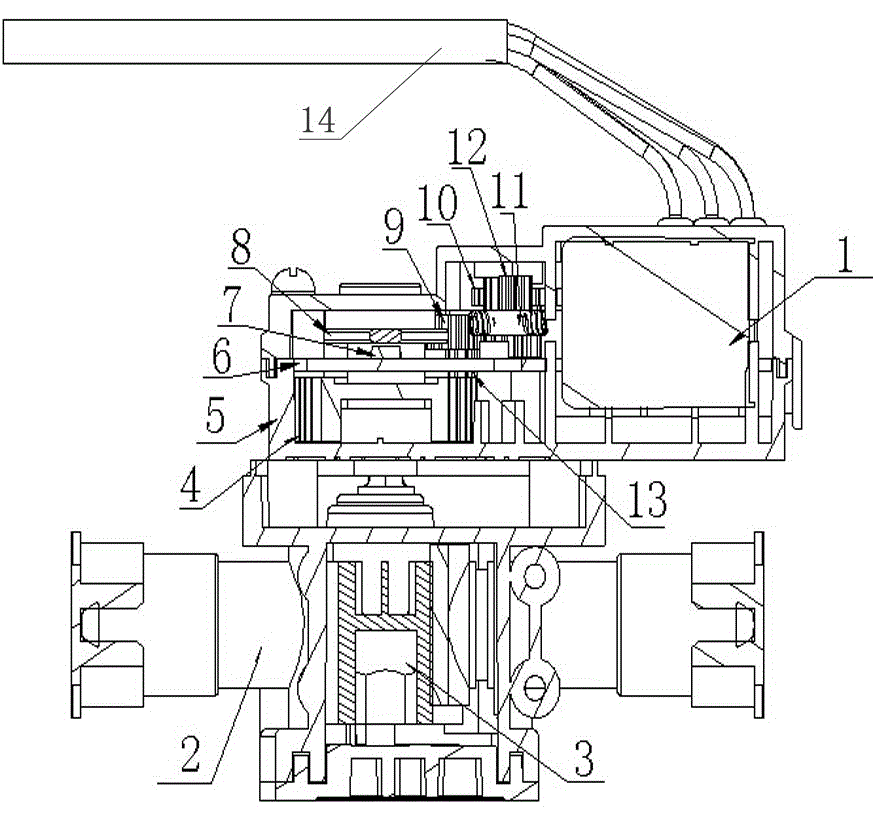

[0016] The present invention as figure 1 , 2 shown.

[0017] Including the micro-motor 1 and the valve body 2, the micro-motor 1 is set on the valve body 2 through the housing 5, wherein the valve core journal passes through the valve body 2 in the housing 5, and the valve core journal passing through the valve body 2 Gear 2 4 is arranged on the top, and a support plate 6 is arranged above the gear 2 4; the journal of gear 2 4 passes through the support plate 6, and an annular magnetic steel 8 is arranged on the journal of gear 2 4, and the annular magnetic steel 8 is lowered The support plate 6 is correspondingly provided with a programmable linear Hall sensor 7; the support plate 6 is provided with a gear one 9, a gear three 10, and a turbine 11, and the gear one 9 meshes with the gear three 10, and the gear three 10 drives the turbine 11, and the turbine 11 Drive the worm 12 to the main shaft of the micro-motor 1; wherein the journal of the first gear 9 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com