Mine steel wire rope automatic collecting device with rope discharging function

A technology of wire rope and rope arrangement, which is used in transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problems of time-consuming and laborious, large disassembly space, and disordered wire ropes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. ⅡⅢⅠ

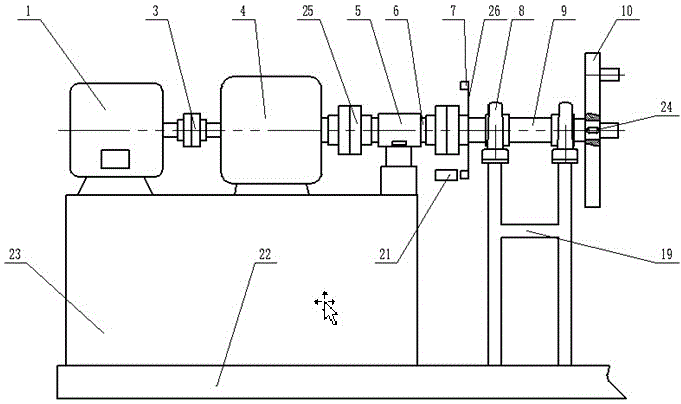

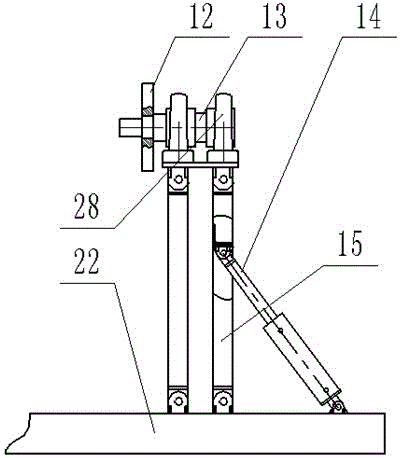

[0033] as attached figure 1 , attached figure 2 And attached image 3 As shown in the figure, a mine-used steel wire rope automatic rope-receiving device with the function of arranging ropes is implemented. The device is that the power of the explosion-proof motor 1 is decelerated by the reducer 4 and then output to the intermediate shaft 6, and the torque sensor 5 is installed on the shaft 6. The shaft 6 is connected with the drive shaft 9 through the shaft coupling II 25 , and the drive shaft 9 is installed on the drive support frame 19 through the bearing seat 8 . The driving lever 10 is installed on the drive shaft 9 through the key 24, so that the power is transmitted to the driving lever 10 through the key 24. A speed-measuring turntable 26 is installed on the intermediate shaft 6, and 12 speed-measuring distance blocks 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com