Automatic feeding double cylinder lifting device

A lifting device and automatic feeding technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve the problems of unstable single-cylinder lifting device, tilting of the table top, noodle running skew, etc., to optimize production space and resources , Optimized manufacturing, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

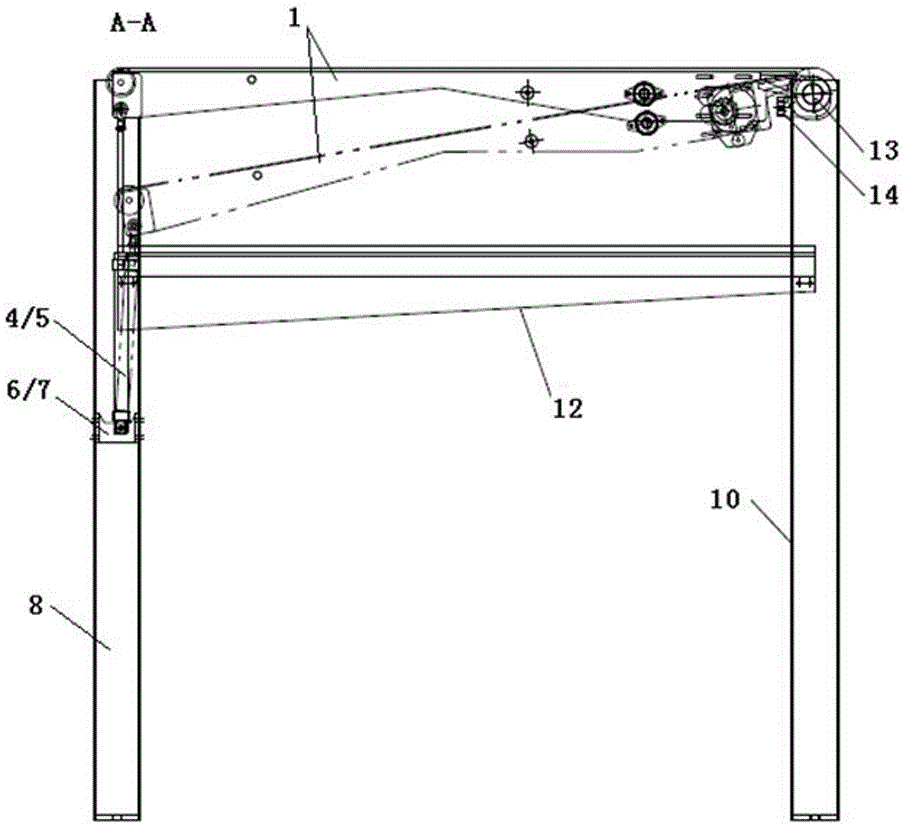

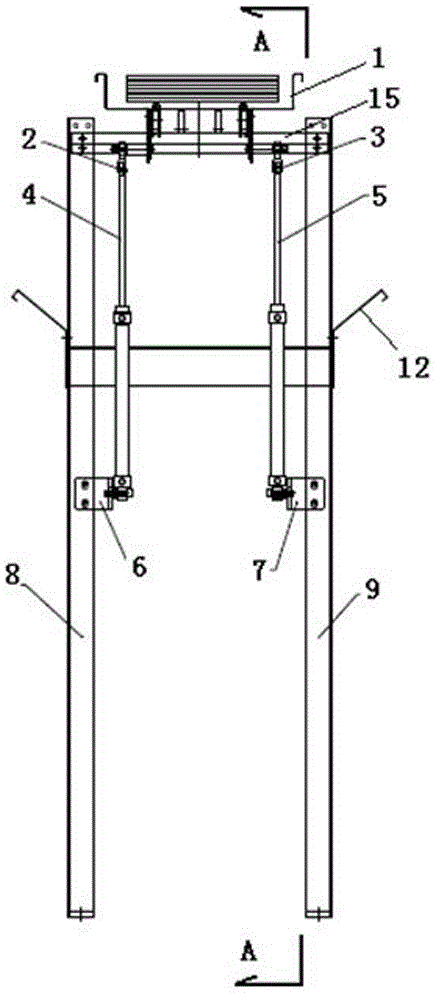

[0009] Depend on figure 1 , figure 2 It can be seen that a kind of automatic feeding double-cylinder lifting device of the present invention includes a conveying table panel 1, a left joint bearing 2, a right joint bearing 3, a left cylinder 4, a right cylinder 5, a left cylinder seat plate 6, a right cylinder seat plate 7, Left front outrigger 8, right front outrigger 9, left back outrigger 10, right back outrigger 11, receiving pan 12, rotating shaft 13, rotating shaft support 14, beam 15, left front outrigging leg 8, right front outrigging leg 9, Left rear support leg 10, right rear support leg 11 and crossbeam 15 form frame (the four jiaos of the rectangular frame that four crossbeams 15 constitute are connected with four support legs respectively; Material receiving tray 12 also can be used as a part of frame, or in The beams are also connected between the lower parts of the four legs). Both sides of the front end of the conveying table panel 1 are respectively fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com