A method for reducing the unqualified rate of crimping of large-section wire tension clamps

A technology of tension-resistant clamp and unqualified rate, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of insufficient levelness of steel cored aluminum wires, improper crimping methods, and large distance differences, etc., to reduce construction quality. The pass rate, the improvement of construction efficiency, and the effect of simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following specific examples further describe the present invention in detail, and the following examples are only descriptive, not limiting, and cannot limit the protection scope of the present invention with this.

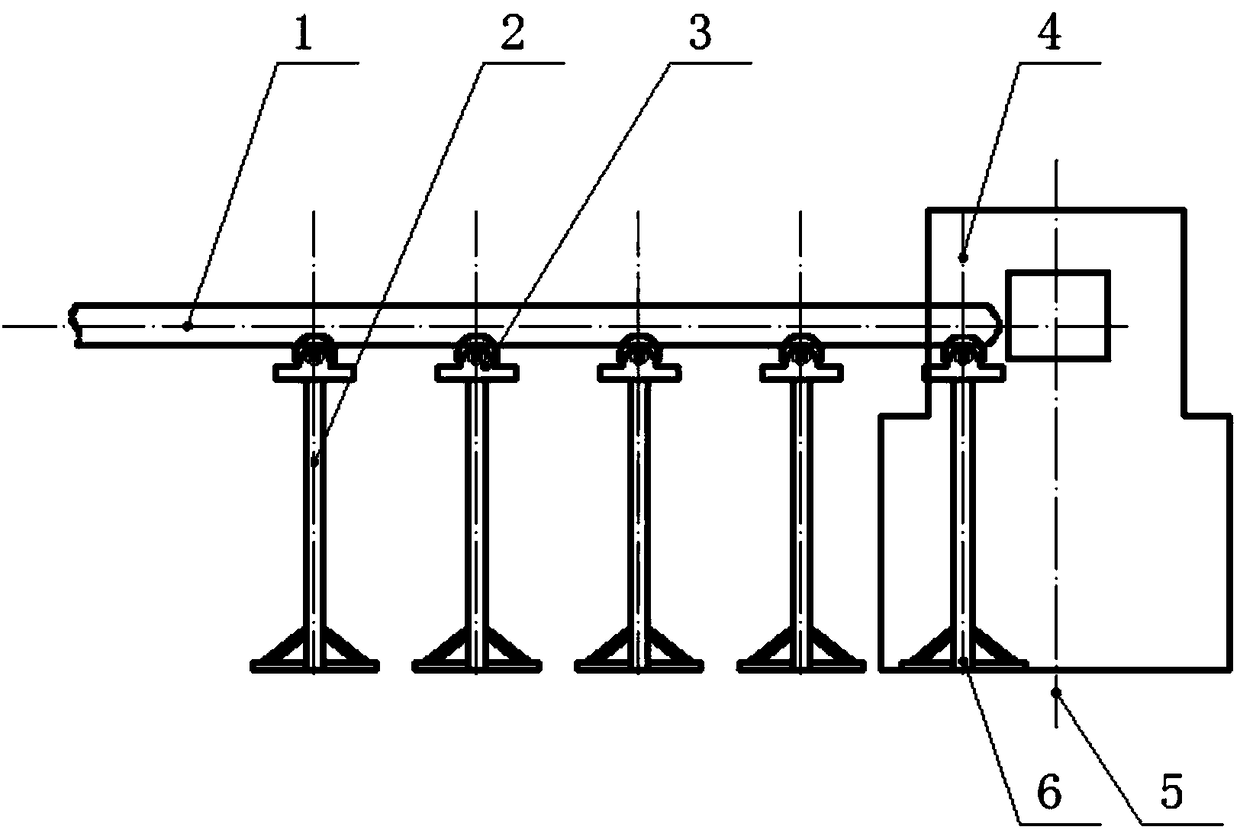

[0025] A method for reducing the unqualified rate of large cross-section wire tension clamp crimping, the steps are: clamp preparation→conductor off-line→clamp cleaning→conducting wire through pipe→steel core crimping→clamp crimping→data measurement, The innovation of this method lies in:

[0026] ⑴Add the following steps to the online clip preparation process:

[0027] Mark the crimping marks on the wire clips; mark the crimping marks on the wire clips according to the standard width size specified for crimping, the number of crimping marks is the same as the number of crimping, the interval between the marks is even, and the lines are clear;

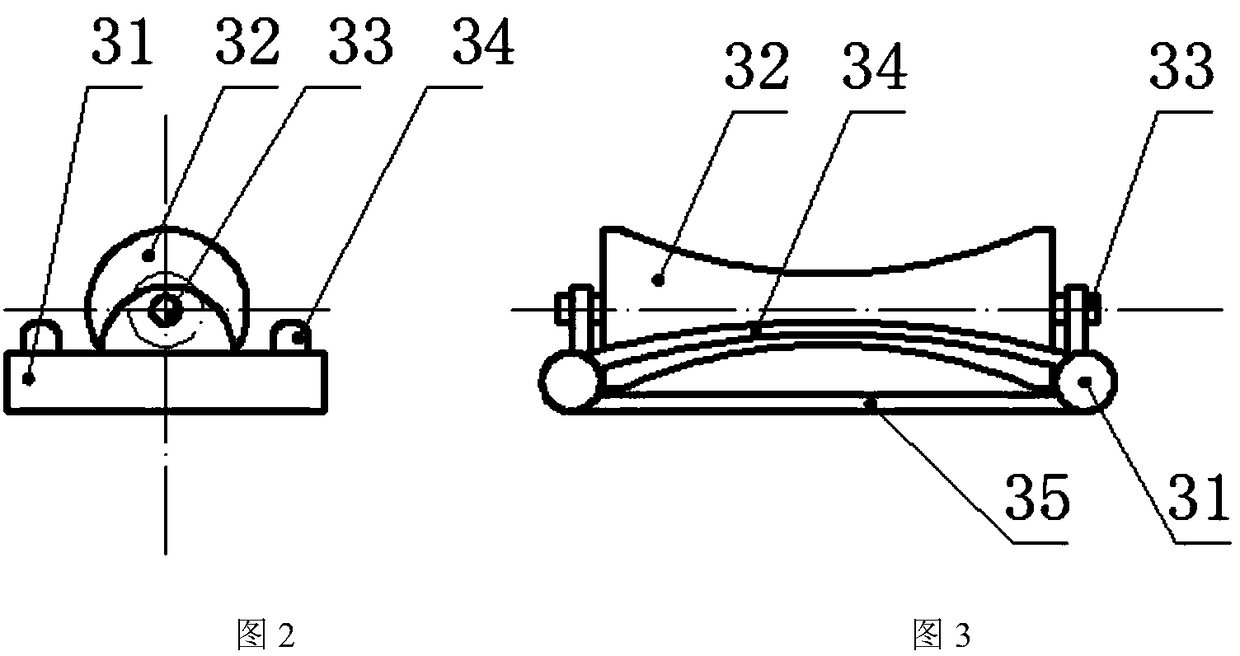

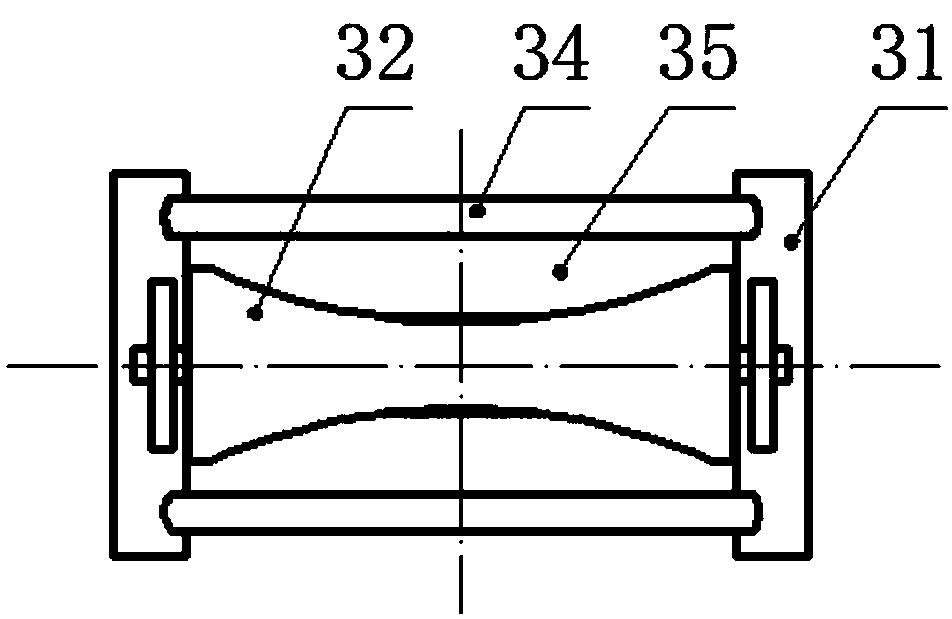

[0028] In this embodiment, the length of the clamp is 760mm, and the crimping width of the steel mold G32 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com