Flexible LED lamp strip

An LED light strip and flexible technology, applied in the direction of slender light source, lighting device, light source, etc., can solve the problems of poor contact, easy circuit breakage, and unstable circuit board position, and achieve the effect of simple structure and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

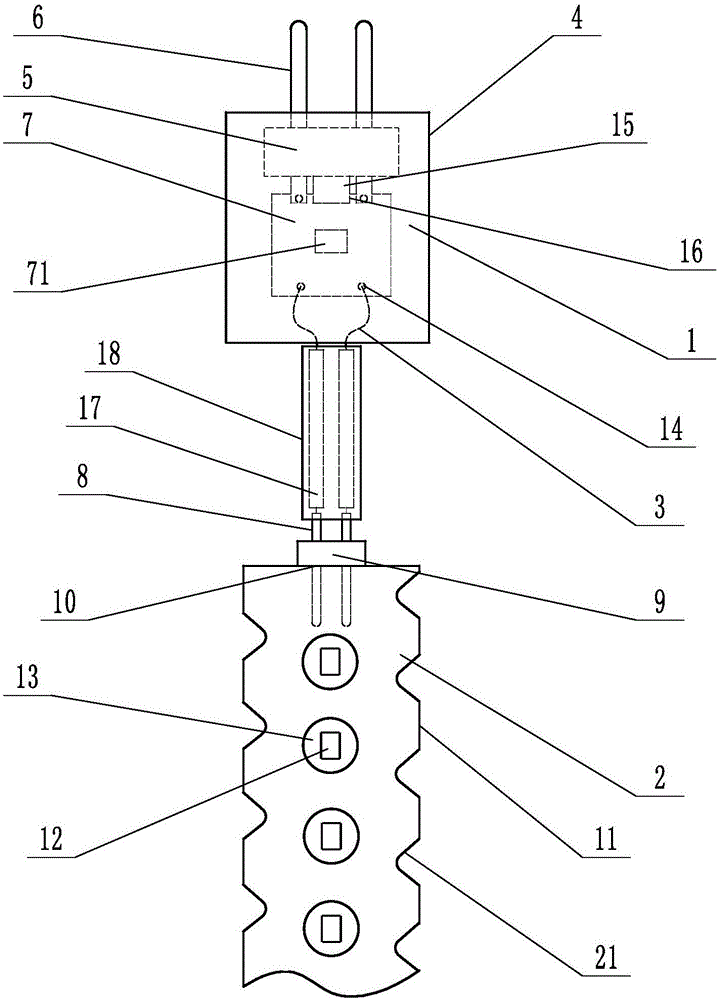

[0017] Such as figure 1 As shown, a flexible LED light strip includes a light strip body 2 and a power plug 1 connected to the light strip body 2. The light strip body 2 includes a strip-shaped FPC soft board 11, and the two sides of the FPC soft board 11 are respectively provided with Several recesses 21, the light strip body 2 adopts the FPC soft board 11 to make the light strip body 2 realize bending and twisting, so that the flexible LED light strip can be laid in various complicated environments. The circuits for electrical connection of several light emitting sources are respectively provided with recesses 21 on both sides of the FPC soft board 11, so that when the FPC soft board 11 is twisted and bent, the circuit arranged on the FPC soft board 11 will not break. The power plug 1 includes two shells 4 that cover each other, a first insulating fixed body 5 fixedly connected with the shells 4, and two conductive pins 6 fixed on the first insulating fixed body 5, which are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com