Vertical axis fan

A technology of vertical axis and fan, applied in the directions of wind turbines, wind motor combinations, and wind turbines at right angles to the wind direction, etc. It can solve the problems of high wind speed at start-up, difficulty in starting power generation, and large volume, so as to achieve large total power generation and increase Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

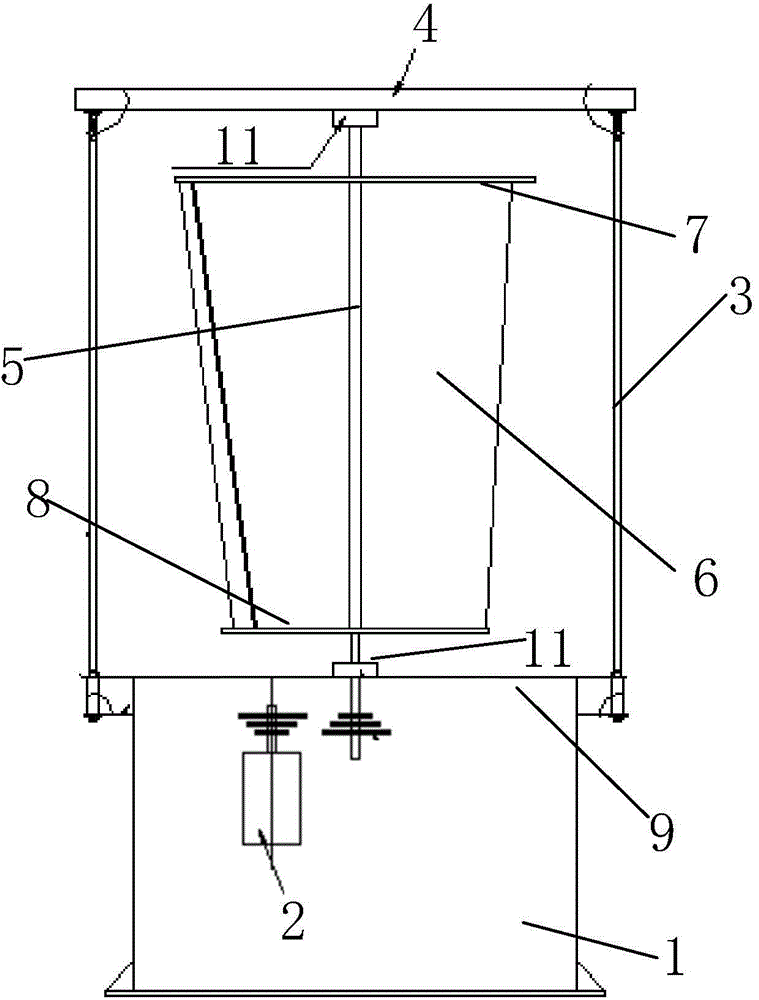

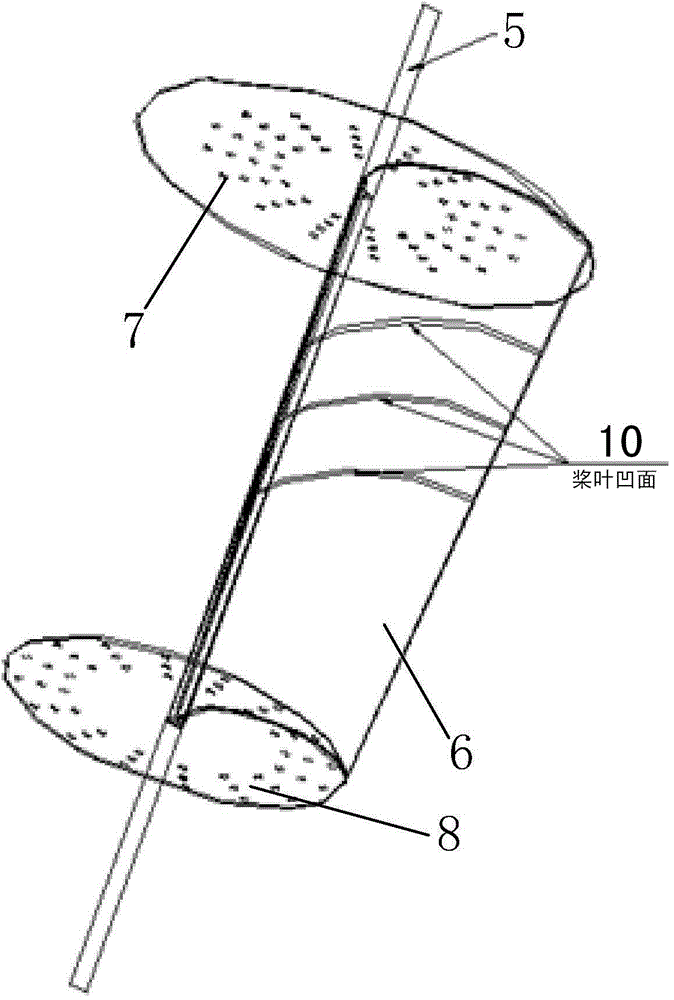

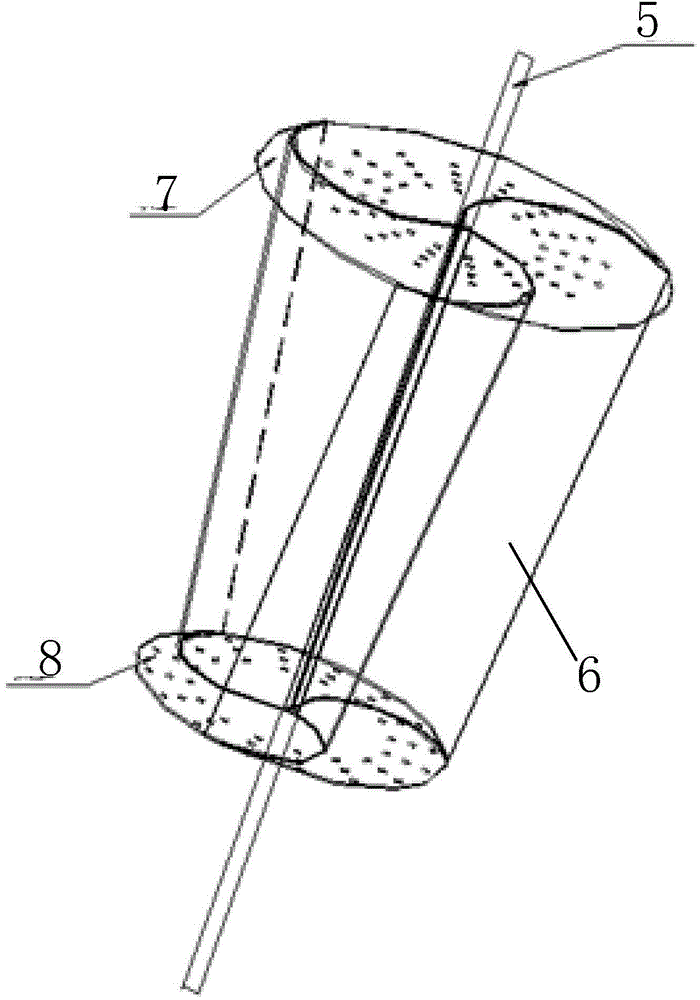

[0025] Such as Figure 1 to Figure 3 As shown, the vertical axis fan according to the embodiment of the present invention includes a chassis 1, a generator 2, two pulling steel rods 3, a fixed beam 4, a main shaft 5 and three blades 6, wherein:

[0026] The three paddles 6 are evenly distributed along the circumference of the main shaft 5 and are fixedly connected with the main shaft 5. The paddles 6 are a curved surface and the radius of curvature gradually increases from bottom to top. Above the paddles 6 A top plate 7 and a chassis 8 are respectively installed on the bottom and bottom, and the top plate 7 and the chassis 8 are both sleeved on the main shaft 5 and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com