Catalyst components for preparing polyolefins for fiber, methods for their preparation and use, catalyst systems and uses, and methods for polymerizing olefins

A catalyst and polyolefin technology, applied in the application field of catalyst system, can solve the problems of wide molecular weight distribution of polyolefin, unsuitable for use as fiber material, low catalytic activity, etc., and achieve narrow molecular weight distribution, excellent kinetic performance, high The effect of polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

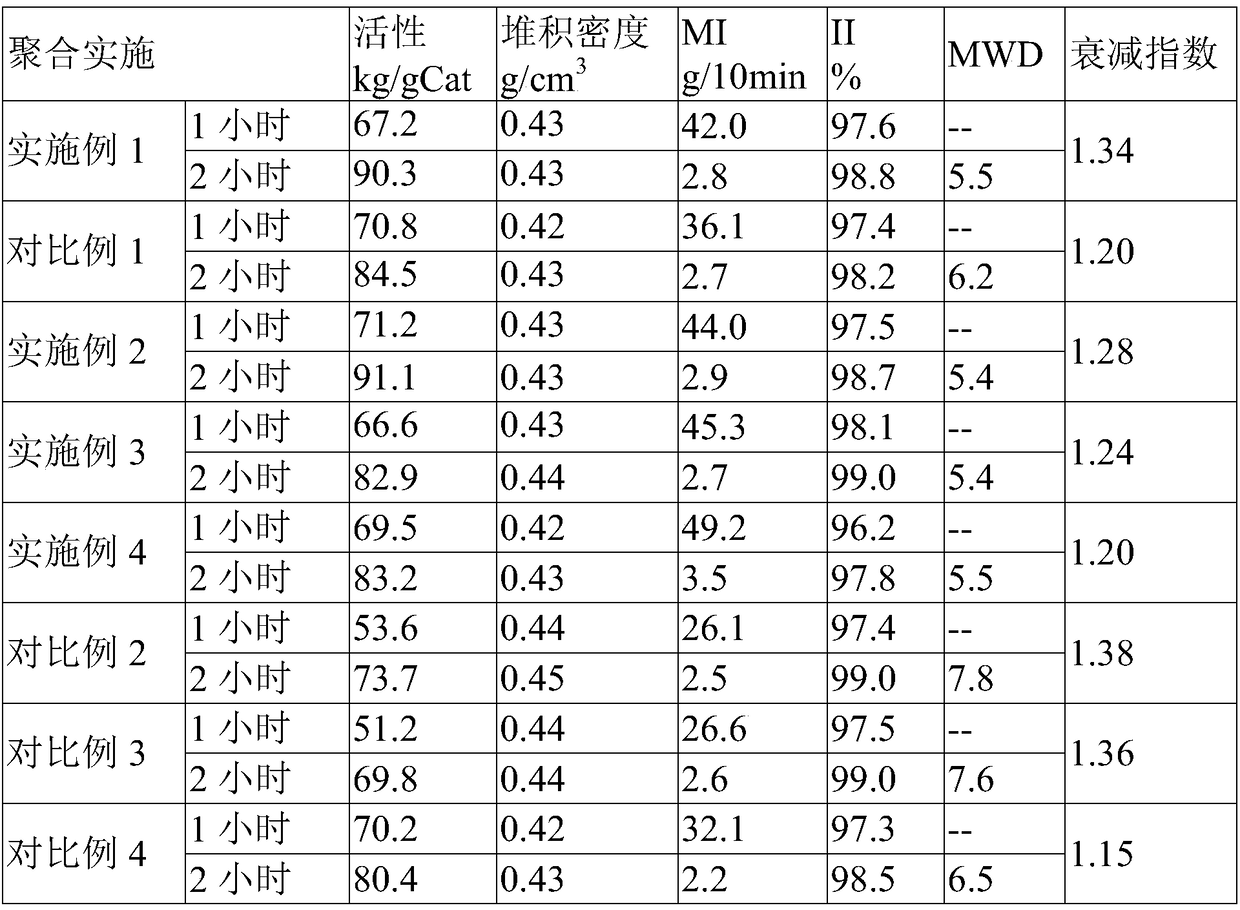

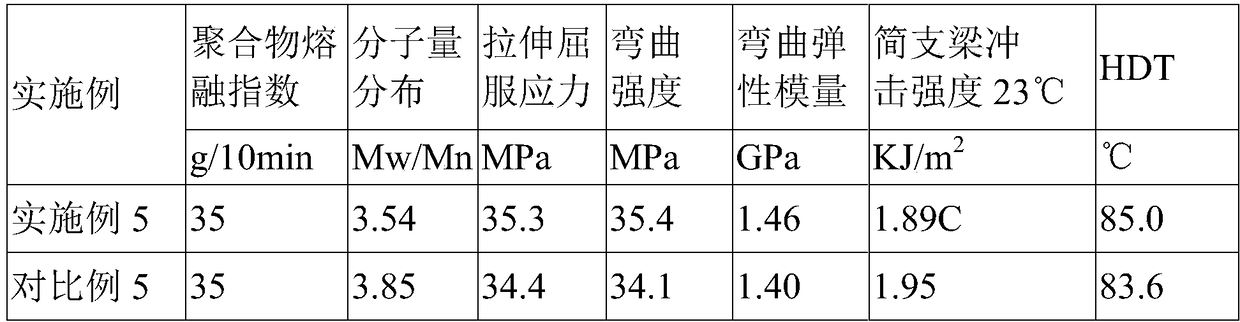

Examples

preparation example Construction

[0031] The invention provides a method for preparing a catalyst component for preparing polyolefin fibers, which may include the following steps: (1) performing a first contact reaction with a magnesium halide and an alcohol compound in the presence of a hydrocarbon solvent to form homogeneous solution; (2) in the presence of a precipitation aid, the homogeneous solution obtained in step (1) is subjected to a second contact reaction with a titanium compound to obtain a mixture containing solid precipitation; (3) the mixture obtained in step (2) is Carry out the third contact reaction with the electron donor compound d in the first part to obtain a suspension; (4) carry out the solid component obtained by solid-liquid separation of the suspension obtained in step (3) and the second part of the titanium compound, the second part The internal electron donor compound d is subjected to the fourth contact reaction, and then the liquid is filtered to obtain a solid product; (5) the so...

Embodiment approach

[0061] According to a preferred embodiment of the present invention, the method for preparing the catalyst solid component of polyolefin for fiber provided by the present invention can be carried out according to the following steps:

[0062] (1) Under a hydrocarbon solvent, anhydrous magnesium chloride and an alcohol compound are subjected to the first contact reaction at 30-150° C. (preferably 60-140° C.) for 0.5-10 hours (preferably 0.5-6 hours) to obtain a uniform Alcohol solution, wherein the molar ratio of anhydrous magnesium chloride to alcohol compounds is 1:2-4 (preferably 1:2.5-3.5);

[0063] (2) Add diol ester compound (separation aid a), aliphatic or aromatic carboxylic acid ester compound (separation aid b) and titanate compound (separation aid c) to the above alcohol In the compound solution, the molar ratio of anhydrous magnesium chloride to the glycol ester compound is 1:0.005-0.1 (preferably 1:0.01-0.05), and the molar ratio of anhydrous magnesium chloride to ...

Embodiment 1

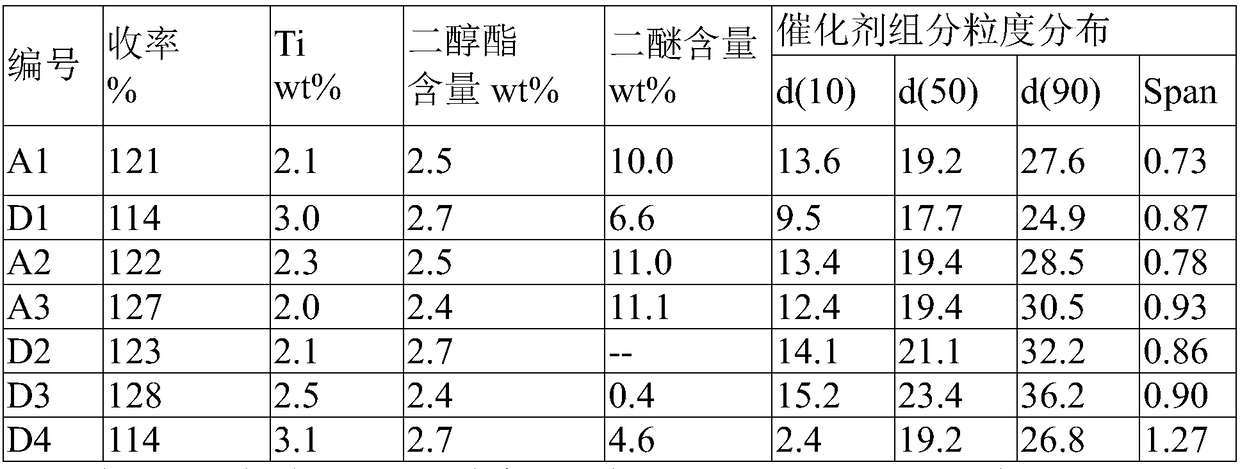

[0108] (1) Preparation of Catalyst Component A1

[0109] (1) In the reactor that has been repeatedly replaced with high-purity nitrogen, add 3.150mol (300.0g) of anhydrous magnesium chloride, 19.68mol (2.1L) of toluene, and 8.4mol (1.1L) of 2-ethylhexanol in sequence , under the conditions of a stirring speed of 450rpm and a temperature of 110°C, the reaction was carried out for 3.0 hours to obtain a stable and uniform alcoholate solution;

[0110] (2) Add 3,5-heptanediol dibenzoate 48mmol (24ml), diisobutyl phthalate 336mmol (90ml) and tetrabutyl titanate 132mmol (45ml) to the above alcoholate solution , stirred for 60 minutes, cooled to room temperature to obtain a homogeneous solution; the above homogeneous solution was added to fully replaced by nitrogen, and equipped with 60mol (6.6L) of titanium tetrachloride and 11.4mol (1.2L) of toluene at -20°C In the reactor, they were fully contacted at -20°C by stirring. After 5 hours, the temperature was raised to 100°C. During t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com