Thermally activated delayed fluorescence material

A technology of heat-activated delayed and fluorescent materials, applied in the direction of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of low efficiency, high price, and unresolved lifespan of blue light materials, and achieve simple synthesis and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

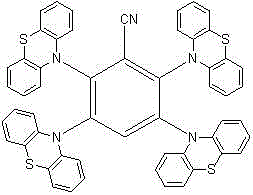

[0089] Synthesis of C1. Under a nitrogen atmosphere, dissolve 1 mol of potassium tert-butoxide into 20 ml of DML and stir for 1 hour, then add 1 mol of carbazole in the DML solution dropwise, and stir for 1 hour after all the addition is complete. Then, a DMF solution in which 0.2 mol of 2,3,4,5,6-pentafluorobenzonitrile was dissolved was added dropwise and stirred for 5 hours. Then the reaction solution was poured into water and filtered to obtain a solid. Separation with a chromatographic column. C1 was obtained with a yield of 90%.

[0090] Mass spectrum: 929.

[0091] Elemental analysis: C: 86.60, H: 4.35, N: 9.05.

Embodiment 2

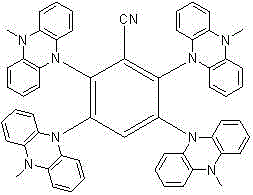

[0093] Synthesis of C2. The reactant carbazole was replaced by tert-butyl carbazole, and C2 was obtained through the same synthesis method as in Example 1, with a yield of 91%.

[0094] Mass spectrum: 1490.

[0095] Elemental analysis: C: 86.20, H: 8.16, N: 5.64.

Embodiment 3

[0097] Synthesis of C3. The reactant carbazole was replaced by phenylcarbazole, and C3 was obtained through the same synthesis method as in Example 1, with a yield of 91%.

[0098] Mass spectrum: 1689.

[0099] Elemental analysis: C: 90.20 H: 4.83 N: 4.97.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com