Lifter with ultralow mounting distance

An installation distance and lifter technology, applied in the field of lifters, can solve the problems of large installation distance, unsteady lifting process, small stroke, etc., and achieve the effects of stable operation, reduced size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

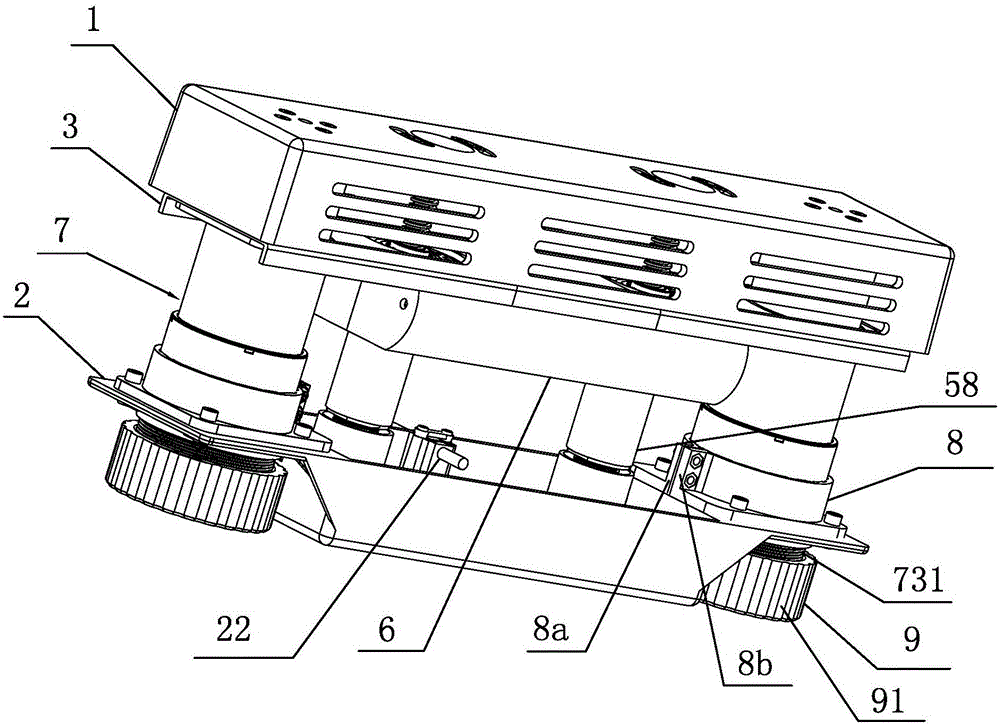

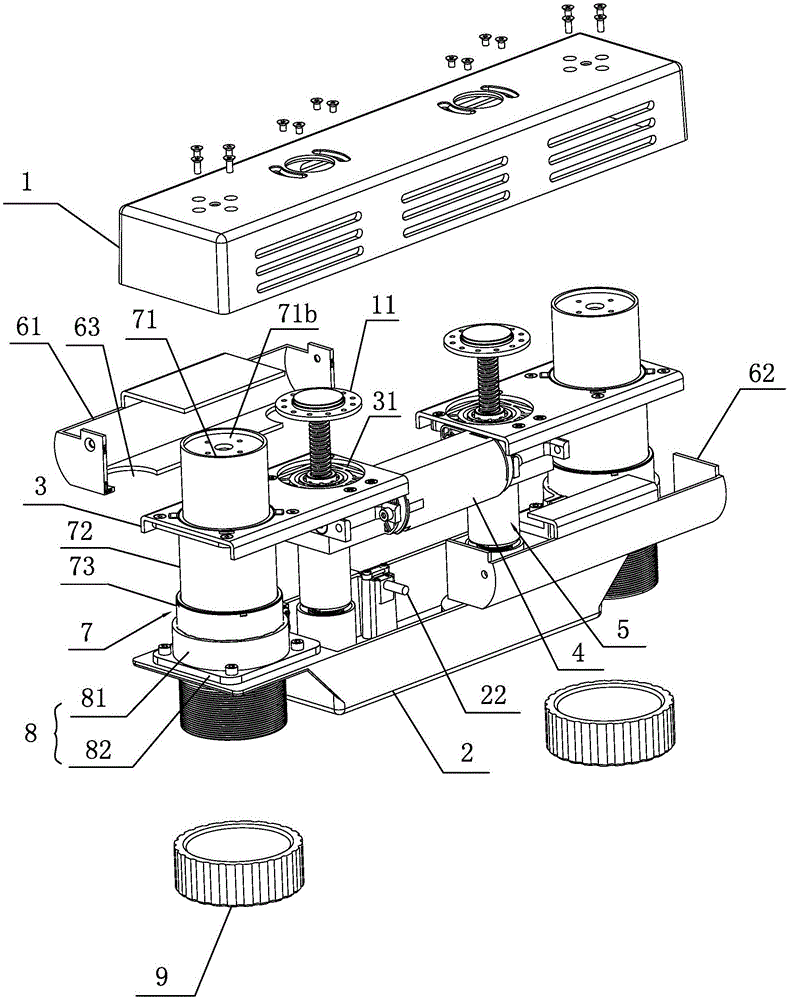

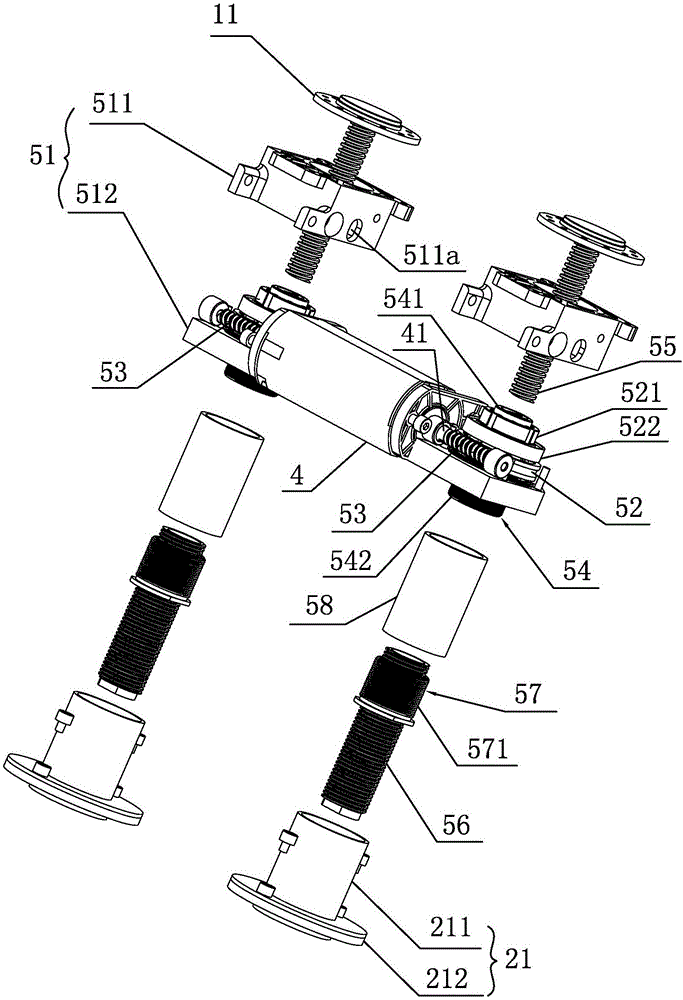

[0021] like Figure 1 to Figure 3 As shown, the present invention provides a lifter with an ultra-low installation distance, including a first installation board 1, a second installation board 2, a third installation board 3 between the first installation board 1 and the second installation board 2 And the driving device that can drive the second mounting plate 2 and the third mounting plate 3 to lift, the driving device includes a driving motor 4 and two driving mechanisms 5 that have output shafts 41 at both ends, and each output shaft 41 of the driving motor 4 is Cooperate with a driving motor 5 in transmission, the driving mechanism 5 includes a gear box 51 installed on the third mounting plate 3, a worm wheel 52 arranged in the gear box 51, an output shaft 41 connected to the driving motor 4 and extending into the gear box 51 The worm 53 meshed with the worm wheel 52, the first drive nut 54 connected to the worm wheel 52, the first screw 55 threaded with the first drive n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com