Overhauling method of steel wire ropes of elevators

A steel wire rope and elevator technology, which is applied in the field of maintenance of elevator steel wire ropes, can solve problems such as work-related injuries or deaths, short time required, and inadequate coordination, and achieve the goal of reducing unsafe factors of elevator steel wire ropes, reducing omissions and negligence, and reducing judgment deviations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

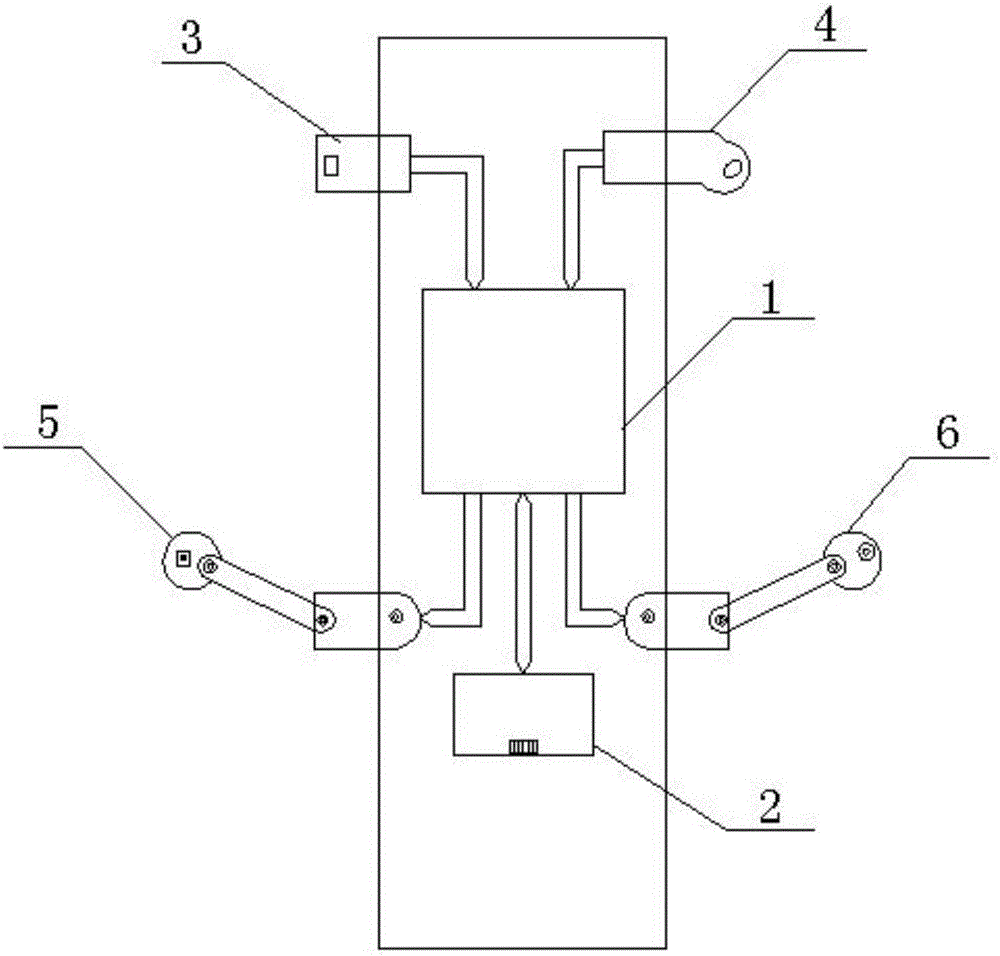

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of these embodiments is used to help understand the present invention, but does not constitute a limitation to the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

[0034] A method for overhauling elevator wire ropes includes the following steps:

[0035] (1) After driving the elevator car to the penultimate floor closer to the top floor without load, stop running;

[0036] (2) Connect the wire ropes on both sides of the top of the elevator car together, and fix the wire ropes through the clamping block and fixing screws;

[0037] (3) Set the elevator to the inspection state in the elevator machine room, and restore the car top inspection and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com